A non-destructive measurement system for fat/lean meat thickness of pork half-carcass based on near-infrared light

A near-infrared light and measurement system technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems affecting the measurement accuracy of fat and lean meat thickness, meat dragging deformation, large volume, etc., to achieve low power consumption and easy operation Convenience and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The implementation of the present invention will be further described in detail below with reference to the accompanying drawings.

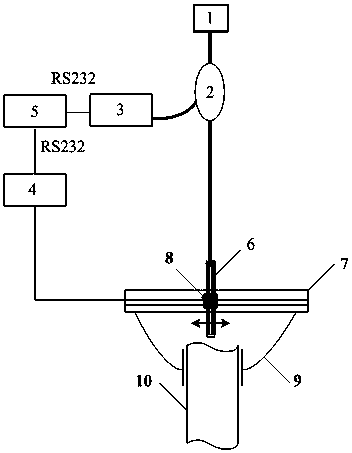

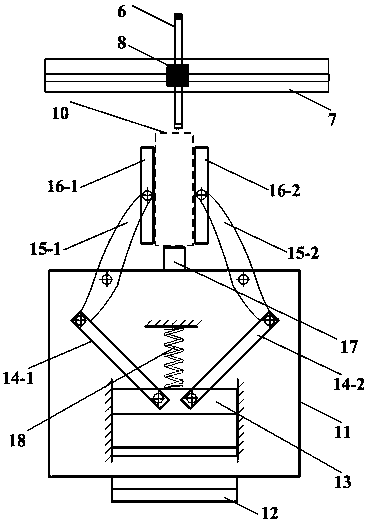

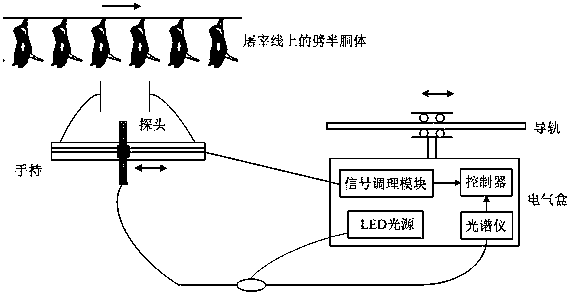

[0032] attached figure 1 Schematic diagram of the pig carcass fat / lean thickness measurement system.

[0033] It includes a near-infrared emission light source 1, a spectrometer 3, a conductive fiber 2, a probe 6, a pig carcass clamping device 9, a displacement detection device 7, a signal conditioning module 4, and a controller 5. 10 is the half-split pig carcass to be measured.

[0034] The near-infrared emission light source 1 is an LED single light source with a wavelength of 800 nm.

[0035] The spectrometer 3 is an EQ2000 spectrometer with a wavelength range of 380nm-960nm and an optical resolution of 1.58nm. The spectrometer 3 inputs the spectral signal to the controller 5 through the RS232 serial port. The spectral signal is the reflection intensity value of each wavelength.

[0036] The conducting fiber 2 is a Y-shaped dual-mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com