Weathering resistant steel structure and high-strength bolt anti-sliding connecting method based on press-in particles

A technology of high-strength bolts and connection methods, which is applied in building structures and constructions, can solve the problems of easily destroying protective films, reducing service life, and inability to take into account weather resistance, and achieves simplified construction technology, reduced service life, and excellent anti-slip. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

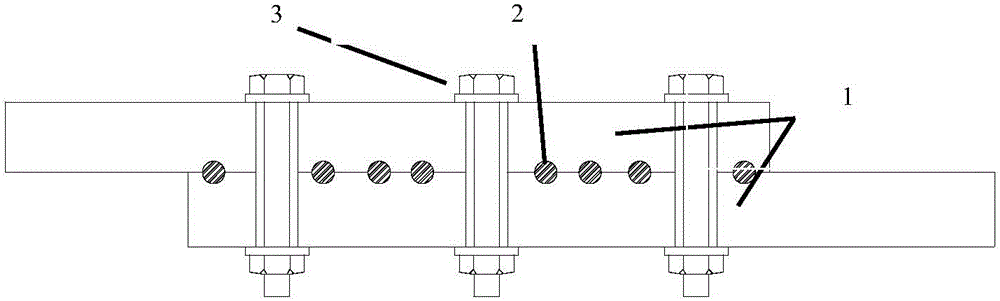

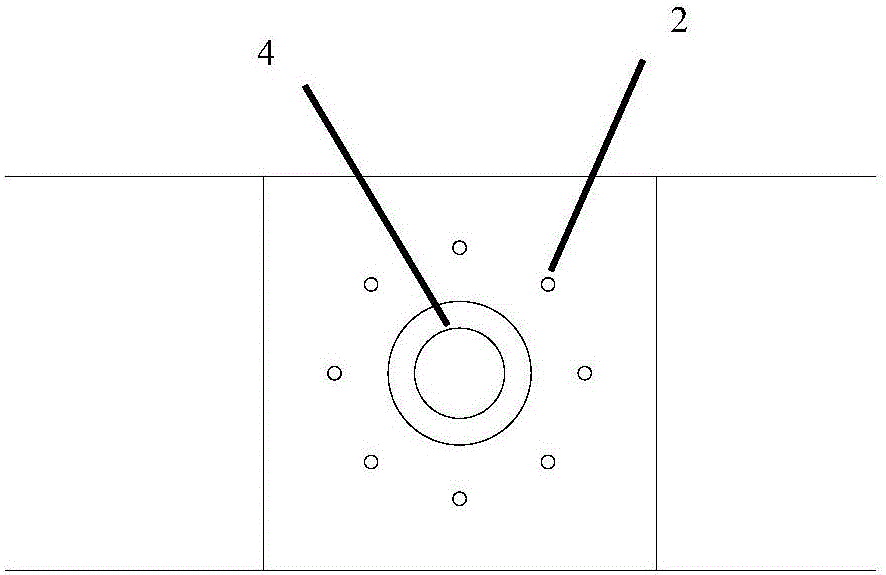

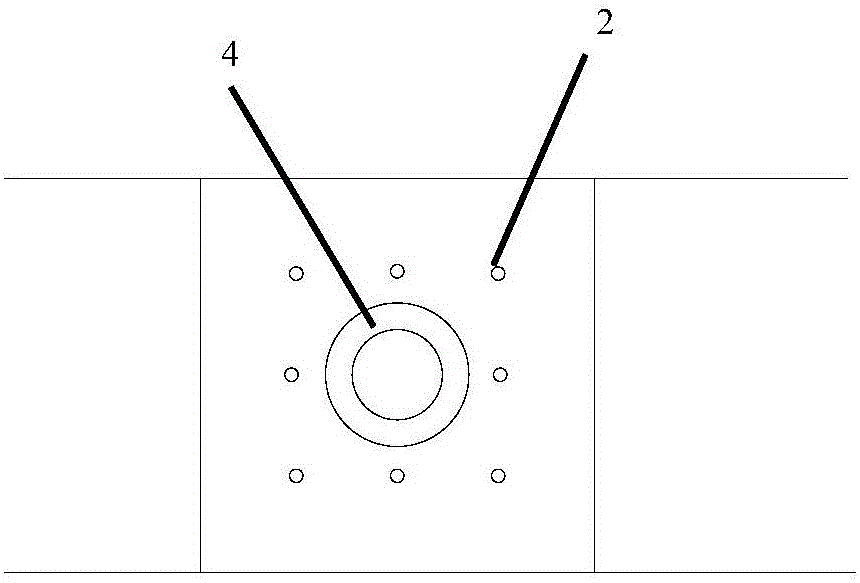

[0026] Such as Figure 1-3 As shown, a method for anti-slip connection of high-strength bolts in weathering steel structures based on pressed particles, the method includes steel connecting plates 1, pressed particles 2 and high-strength bolts 3;

[0027] The steel connecting plate 1 and the high-strength bolt 3 are made of weather-resistant steel; the pressed particles 1 are made of a corrosion-resistant metal material with high hardness, high rigidity and good toughness, and the hardness of the particles is more than 1.5 times that of the weather-resistant steel plate;

[0028] The two steel connecting plates 1 are connected together by high-strength bolts 3, and the contact surfaces of the two steel connecting plates are provided with pressed particles to form an anti-slip surface, and the pressed particles surround the bolts on the steel co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com