Fixed three-layer composite shock absorber

A shock absorbing device and layer compounding technology, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of poor resetting after earthquakes, easy aging of rubber, large vertical bearing capacity, etc., and achieve the effect of convenient restoration and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

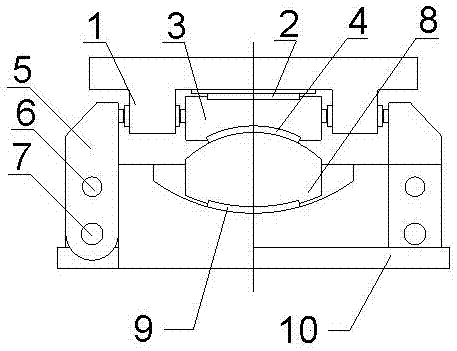

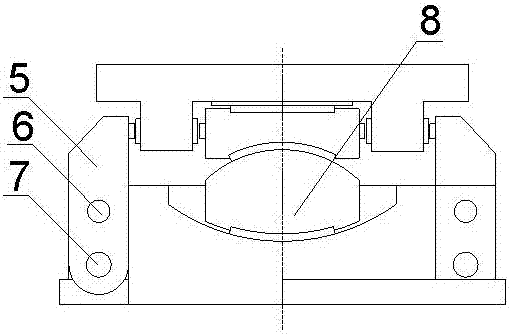

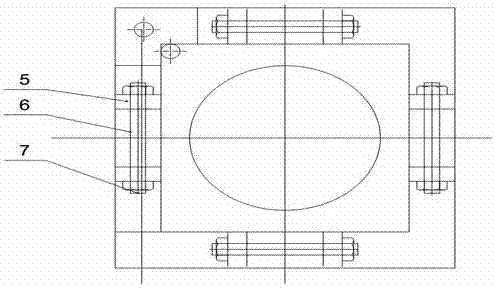

[0033] The fixed three-layer composite damping device of the present invention includes an upper seat plate 1, a flat slide plate 2, an upper pendulum 3, an upper spherical slide plate 4, a block assembly 5, a shear pin 6, a connecting hinge shaft 7, a ball pendulum 8, and a lower spherical slide plate 9 and hem 10, the upper and lower surfaces of the ball pendulum 8 are arc-shaped surfaces, and the left and right surfaces are planes. The upper pendulum 3 and the upper seat plate 1 slide relatively to form a plane sliding layer; the upper pendulum 3 and the ball pendulum 8 rotate relatively to form a rotating layer; the ball pendulum 8 and the lower pendulum 10 relatively swing to form a swing layer; The upper seat plate 1 and the upper pendulum 3, the upper pendulum 3 and the ball pendulum 8, and the ball pendulum 8 and the lower pendulum 10 form a three-layer composite movement. In order to make the relative sliding between the upper seat plate 1 and the upper pendulum 3, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com