Preparation method of rare earth metal

A technology of rare earth metals and rare earth salts, applied in the field of rare earths, can solve the problems of high price, high energy consumption, and high cost of rare earth metals, and achieve the effects of reducing outgassing, saving energy consumption, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

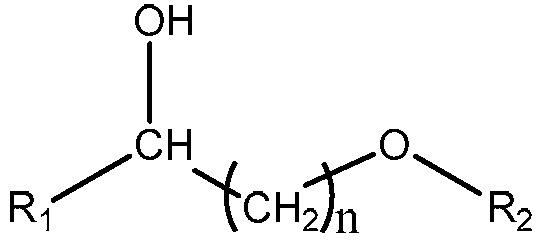

[0030] It can be seen from the background technology that the existing methods for preparing rare earth metals using ionic liquids have disadvantages such as high cost, high energy consumption, cumbersome operation due to the use of solid additives, and the need to operate in a glove box, which limits its industrial application. The inventors of the present invention have conducted research on the above problems and provided a method for preparing rare earth metals. The preparation method includes the following steps: mixing rare earth salts, ionic liquids, and hydroxyl ether solvents to form an electrolyte, and placing the electrolyte in In the electrolytic cell; the electrolytic solution is electrolyzed to form rare earth metals; wherein, the structural formula of the hydroxy ether solvent is:

[0031]

[0032] Among them, R 1 is any of hydrogen, methyl, ethyl, n-propyl, isopropyl, n-butyl, isobutyl and tert-butyl; R 2 Any one of methyl, ethyl, n-propyl, isopropyl, n-but...

Embodiment 1

[0045] This embodiment provides a method for preparing rare earth metals, comprising the following steps:

[0046] First, the LaCl 3 , ionic liquid and 2-hydroxypropyl methyl ether are mixed to form an electrolyte, and the electrolyte is placed in an electrolytic cell, wherein the volume ratio of the ionic liquid to 2-hydroxypropyl methyl ether is 10:1, and the rare earth salt The content in the electrolyte is 5g / L, and the anion of the ionic liquid is BF 4 - , the cation of the ionic liquid is 1-ethyl-3-methylimidazolium cation;

[0047] Then, the serpentine tube feeds nitrogen gas into the electrolytic cell to aerodynamically stir the electrolyte, and pre-electrolyze the electrolyte, wherein the current density is preferably 10A / m 2 , the time of pre-electrolysis is preferably 10min.

[0048] Finally, with the inert electrode as the working electrode and the inert electrode as the counter electrode, the electrolyte is electrolyzed by constant current electrodeposition, a...

Embodiment 2

[0050] This embodiment provides a method for preparing rare earth metals, comprising the following steps:

[0051] First, the LaCl 3 , ionic liquid and 2-hydroxypropyl ethyl ether are mixed to form an electrolyte, and the electrolyte is placed in an electrolytic cell, wherein the volume ratio of the ionic liquid to 2-hydroxypropyl ethyl ether is 5:1, and the rare earth salt The content in the electrolyte is 15g / L, and the anion of the ionic liquid is BF 4 - , the cation of the ionic liquid is 1-ethyl-3-methylimidazolium cation;

[0052] Then, the serpentine tube feeds nitrogen gas into the electrolytic cell to aerodynamically stir the electrolyte, and pre-electrolyze the electrolyte, wherein the current density is preferably 10A / m 2 , the time of pre-electrolysis is preferably 20min.

[0053] Finally, with the inert electrode as the working electrode and the inert electrode as the counter electrode, the electrolyte is electrolyzed by constant current electrodeposition, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com