Oil stain removing polishing cream for metal stainless steel and preparation method thereof

A stainless steel and degreasing technology, which is applied in the field of degreasing polishing cream and its preparation, can solve the problems of impracticality and no decontamination effect, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

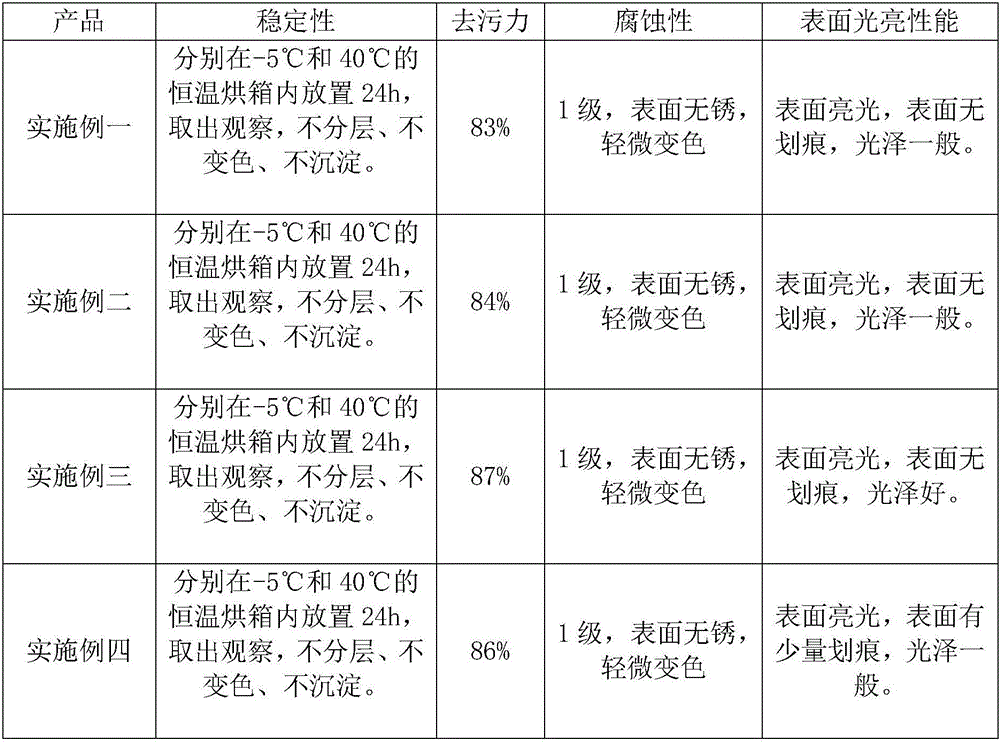

Examples

Embodiment 1

[0021] Weigh 20g of palm wax, 10g of glycerin, and 35g of white oil in container A, melt at 92°C and add 2g of oily dispersant. Stir well, add 10g nano-Al 2 o 3 Powder.

[0022] In container B, weigh 20g of deionized water, add 2g of glyceryl stearate and 5g of NP-10 emulsifier, add 1g of sodium gluconate and 1g of tetrasodium edetate, and stir well.

[0023] Pour the solution in container B into container A, stir for 10 minutes, and obtain the desired cream after cooling.

Embodiment 2

[0025] Weigh 20g of palm wax, 10g of glycerin, and 25g of white oil in container A, melt at 92°C and add 5g of oily dispersant. Stir well, add 10g nano-Al 2 o 3 Powder.

[0026] In container B, weigh 25g of deionized water, add 2g of glyceryl stearate and 5g of NP-10 emulsifier, add 1g of sodium gluconate and 1g of tetrasodium edetate, and stir well.

[0027] Pour the solution in container B into container A, stir for 10 minutes, and obtain the desired cream after cooling.

Embodiment 3

[0029] Weigh 25g of palm wax, 10g of glycerin, and 25g of white oil in container A, and add 4.5g of oily dispersant after melting at 92°C. Stir well, add 15g nano-Al 2 o 3 Powder.

[0030] In container B, weigh 20g of deionized water, add 2g of glyceryl stearate and 5g of NP-10 emulsifier, add 2g of sodium gluconate and 3g of tetrasodium edetate, and stir evenly.

[0031] Pour the solution in container B into container A, stir for 10 minutes, and obtain the desired cream after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com