Manufacturing process for hot-melt textured adhesive tape

A technology of masking tape and manufacturing process, which is applied in the direction of adhesives, film/sheet adhesives, etc., can solve problems such as environmental pollution, adhesive tape is not strong enough, and the thickness of hot-melt masking tape is not thick enough, so as to reduce Effects of production cost, increased thickness and adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

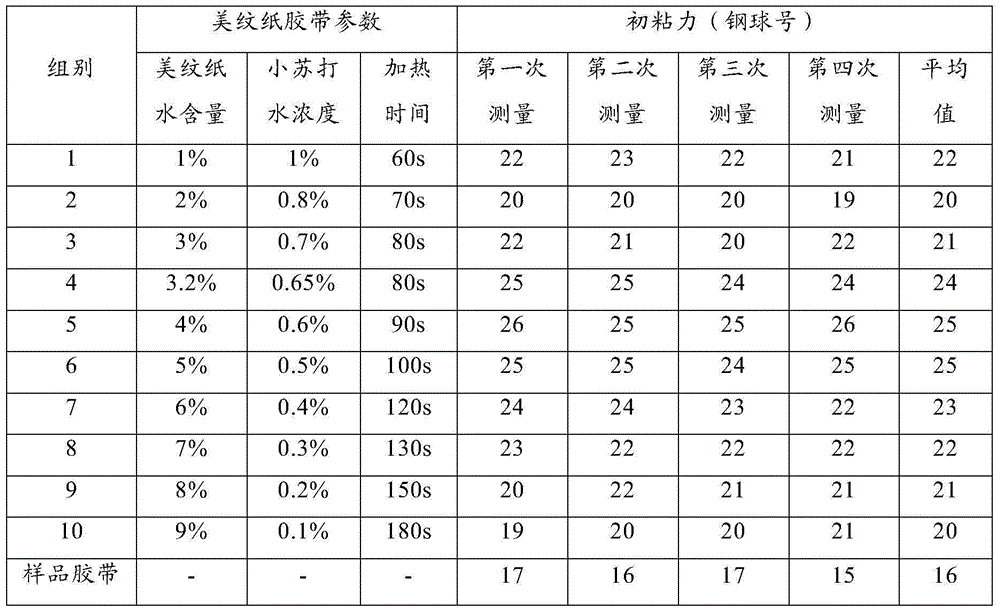

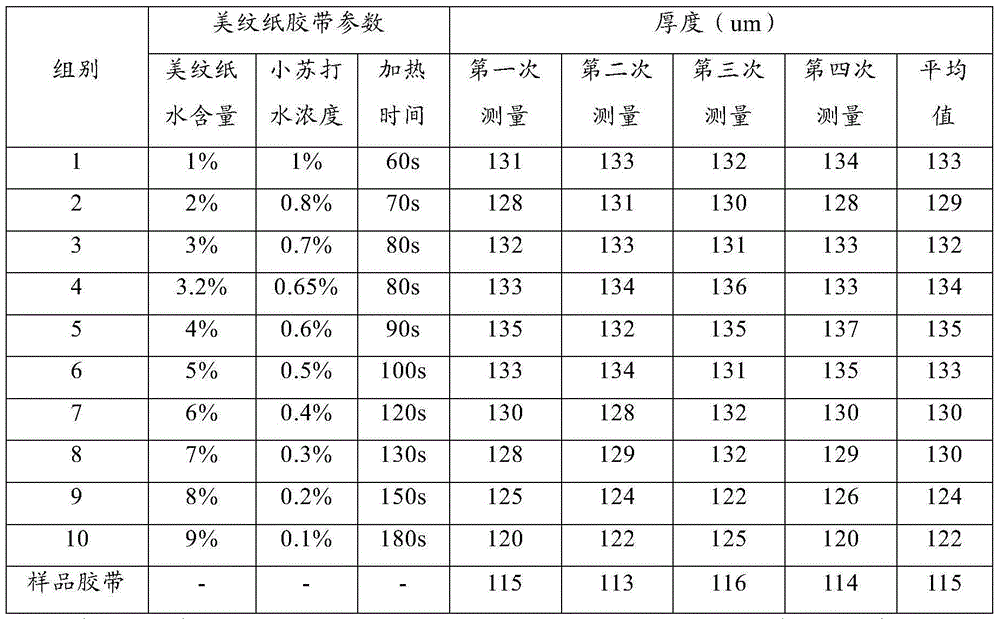

[0023] a. Using impregnated and release-treated masking paper as the base, and controlling the water content in the masking paper to 1% by adjusting the humidity of the space;

[0024] b. Spray baking soda water on the surface of the textured paper to be glued, and use a humidity controller to form a layer of baking soda water vapor film on the surface of the textured paper to be glued. The amount of baking soda used is 0.8g / m 2 ;

[0025] c. Control the temperature at 100-220°C, apply the hot melt adhesive on the surface of the textured paper containing the baking soda water vapor film by extrusion, and control the humidity in the textured paper by adjusting the humidity of the space. The water content is 1%, and the concentration of baking soda aqueous solution is 1%;

[0026] d. Heat the masking paper substrate after gluing for 60s, and the temperature is controlled within the range of 100-250°C. Using the principle that baking soda is preheated and easy to decompose, the ...

Embodiment approach 2

[0028] a. Using impregnated and release-treated masking paper as the base, and controlling the water content in the masking paper to 3.2% by adjusting the humidity of the space;

[0029] b. Spray baking soda water on the surface of the textured paper to be glued, and use a humidity controller to form a layer of baking soda water vapor film on the surface of the textured paper to be glued. The amount of baking soda used is 1.2g / m 2 ;

[0030] c. Control the temperature at 100-220°C, apply the hot melt adhesive on the surface of the textured paper containing the baking soda water vapor film by extrusion, and control the humidity in the textured paper by adjusting the humidity of the space. The water content is 3.2%, and the concentration of baking soda aqueous solution is 0.65%;

[0031] d. Heat the masking paper substrate after gluing for 80s, and the temperature is controlled within the range of 100-250°C. Using the principle that baking soda is preheated and easy to decompos...

Embodiment approach 3

[0033] a. Using impregnated and release-treated masking paper as the base, and controlling the water content in the masking paper to 7% by adjusting the humidity of the space;

[0034] b. Spray baking soda water on the surface of the textured paper to be glued, and use a humidity controller to form a layer of baking soda water vapor film on the surface of the textured paper to be glued. The amount of baking soda used is 1.2g / m 2 ;

[0035] c. Control the temperature at 100-220°C, apply the hot melt adhesive on the surface of the textured paper containing the baking soda water vapor film by extrusion, and control the humidity in the textured paper by adjusting the humidity of the space. The water content is 7%, and the concentration of baking soda aqueous solution is 0.25%;

[0036] d. Heat the masking paper substrate after gluing for 120s, and the temperature is controlled within the range of 100-250°C. Using the principle that baking soda is preheated and easy to decompose, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com