Nano expanding type transparent fireproof paint and preparation method thereof

An intumescent technology for fire-resistant coatings, applied in fire-resistant coatings, coatings, etc., can solve the problems of increasing the covering power of fire-resistant coatings, poor decorative effects of transparent fire-resistant coatings, and poor product transparency, so as to improve the fire protection effect and improve fire protection Protective effect, the effect of a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] In the present embodiment, the preparation method of nano-expansive transparent fireproof coating comprises the following steps:

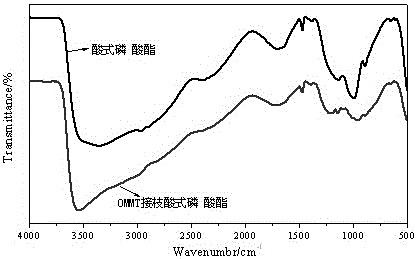

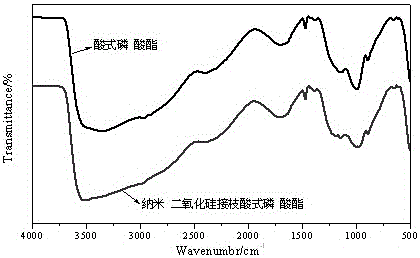

[0055] (1) Preparation of nano-organic montmorillonite grafted acid phosphate

[0056] In a 1L three-necked flask, 100g of nano-montmorillonite Na + -MMT is placed in 200g of deionized water to make a suspension of montmorillonite, and then 2 times the mass of nanometer montmorillonite, that is, 200g of cetyltrimethylammonium bromide CTAB, is completely dissolved in deionized water to prepare a solution 1. Heat the suspension in a constant temperature water bath at 90°C and stir for 0.5 hours, then add solution 1 to react, after 3 hours of reaction, stop heating, and after standing for 24 hours, the product after removing the upper solution is suction-filtered and washed several times until the product No Br in - After that (no light yellow precipitate was detected by AgNO3), it was dried at 80°C for 72 hours, and ground into 150-mesh powd...

Embodiment 2

[0063] In the present embodiment, the preparation method of nano-expansive transparent fireproof coating comprises the following steps:

[0064] (1) Preparation of nano-organic montmorillonite grafted acid phosphate

[0065] In a 1L three-necked flask, 100g of nano-montmorillonite Na + -MMT is placed in the deionized water of 300g to make the suspension of montmorillonite, then the hexadecyltrimethylammonium bromide CTAB of 3 mass times of montmorillonite is dissolved in deionized water completely and is prepared into solution one of 300g , heat the suspension in a constant temperature water bath at 70°C and stir for 1 hour, then add solution 1 to react, after reacting for 5 hours, stop heating, and after standing for 24 hours, the product after removing the upper solution is suction filtered and washed several times until there is no Br - After that (no light yellow precipitate was detected by AgNO3), it was dried at 80°C for 72 hours, and ground into a 300-mesh powder with...

Embodiment 3

[0072] In the present embodiment, the preparation method of nano-expansive transparent fireproof coating comprises the following steps:

[0073] (1) Preparation of nano-organic montmorillonite grafted acid phosphate

[0074] In a 1L three-necked flask, 100g of nano-montmorillonite Na+-MMT was placed in 250g of deionized water to make a suspension of montmorillonite, and then 200g of hexadecyltrimethyl Ammonium bromide CTAB was completely dissolved in deionized water to prepare solution 1. Heat the suspension in a constant temperature water bath at 80°C and stir for 1 hour, then add solution 1 to react. After 4 hours of reaction, stop heating, and after standing for 24 hours, remove the upper layer The product after the solution is suction filtered and washed several times until there is no Br in the product - After that (no light yellow precipitate was detected by AgNO3), it was dried at 80°C for 72 hours, and ground into 200-mesh powder with a ball mill to make nano-organic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com