Multifunctional additives for water-based anticorrosion coatings, anticorrosion coatings and their applications

A multi-functional additive, anti-corrosion coating technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, epoxy resin coatings, etc., can solve the problems of limited use, poor water solubility, poor compatibility, etc. The effect of improved anti-corrosion effect and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

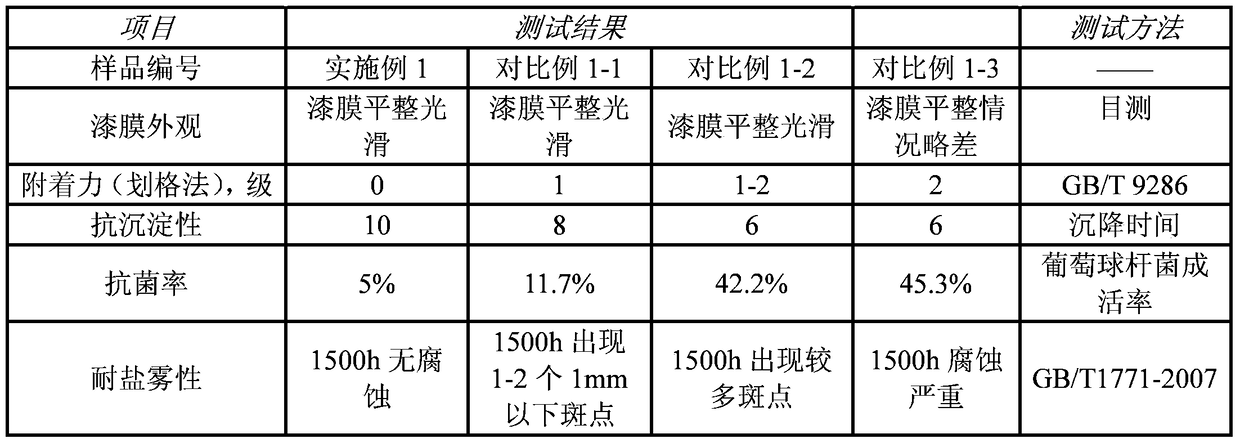

Embodiment 1

[0039] (1) Preparation of multifunctional auxiliary agent: Weigh 30 g of polyvinylpyrrolidone, dissolve it in 10 g of ethylene glycol, slowly add dimethyl sulfate 5 times its molar mass under stirring, and react at room temperature for 12 hours. The product was vacuum-dried at room temperature for 24 hours to obtain modified polyvinylpyrrolidone. Then, the modified polyvinylpyrrolidone and the water-soluble benzotriazole are mixed according to the ratio of 5:1 and dissolved in water to form a multifunctional auxiliary agent, which is packaged for future use.

[0040] (2) Weigh 40g of water-based epoxy emulsion, add 4g of the multifunctional additive for stirring and mixing, add 2g of BYK-154 dispersant, 0.3g of BYK-025 defoamer, 0.3g of MH6000 thickener, triethylenetetramine 3g of curing agent, mixed evenly, coated on the surface of the substrate, performance test after complete curing.

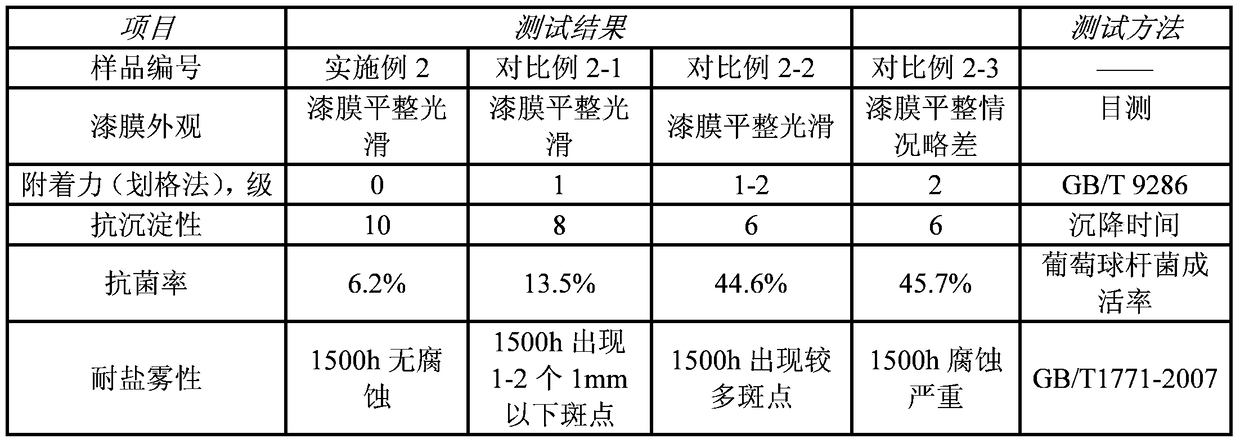

Embodiment 2

[0051] (1) Preparation of multifunctional additives: Weigh 30 g of polyacrylamide, dissolve it in 10 g of ethylene glycol, slowly add benzyl chloride 5 times its molar mass under stirring, and react at room temperature for 12 hours. Remove impurities from the product and dry it in vacuum at room temperature for 24 hours to obtain modified polyacrylamide. Then, the modified polyacrylamide and mercaptobenzothiazole are mixed according to the ratio of 3:1 and dissolved in water to form a multifunctional additive, which is packaged for later use.

[0052] (2) Weigh 60g of water-based polyurethane emulsion, add 4g of the multifunctional additive for stirring and mixing, add 2g of BYK-155 dispersant, 0.3g of BYK-094 defoamer, 0.3g of HS6000YP2 thickener, and XC-205 curing agent 6g, mixed evenly, coated on the surface of the substrate, performance test after complete curing.

Embodiment 3

[0063] (1) Preparation of multifunctional additives: Weigh 30 g of hydroxyethyl cellulose, dissolve it in 10 g of ethylene glycol, slowly add dimethyl sulfate 5 times its molar mass under stirring, and react at room temperature for 12 hours. The product was vacuum-dried at room temperature for 24 hours to obtain modified hydroxyethyl cellulose. Then, the modified hydroxyethyl cellulose and the water-soluble benzotriazole are mixed according to the ratio of 4:1 and dissolved in water to form a multifunctional auxiliary agent, which is packaged for later use.

[0064] (2) Weigh 70g of water-based acrylic emulsion, add 6g of the multi-functional additive for stirring and mixing, add 4g of BYK-102 dispersant, 0.2g of BYK-018 defoamer, 0.1g of MH10000 thickener, and DowXL-29SE curing agent 7g, after mixing evenly, apply on the surface of the substrate, and perform performance test after it is completely cured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com