Nano-composite packaging material capable of inhibiting generation of endogenous formaldehyde in lentinula edodes

A nano-composite, packaging material technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of insufficient cold chain system conditions, unsatisfactory performance of packaging materials, limited practical scope, etc. The production of shiitake mushrooms, the inhibition of endogenous formaldehyde production in shiitake mushrooms, and the effects of low equipment and technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Preparation of embodiment 1 nanocomposite packaging material

[0044] Nano silver Nanjing Hitech Nano Materials Co., Ltd., model: HTB-032;

[0045] Nanometer titanium dioxide Nanjing Haitai Nano Material Co., Ltd., model: HTTi-03;

[0046] Low-density polyethylene Qilu Branch of China Petrochemical Corporation, model: TN26;

[0047] Low-density linear polyethylene Qilu Branch of China Petrochemical Corporation, model: 7042;

[0048] Anti-fogging agent masterbatch Nanjing Institute of Plastics, model: YFW-P;

[0049] SHR-10A high-speed mixer Zhangjiagang Sanxing Jiangfan Machinery Co., Ltd.;

[0050] ZC-65D co-rotating parallel twin-screw extrusion granulator Nanjing Xinhui Machinery Co., Ltd.;

[0051] PEVA double-layer co-extrusion casting machine Quanzhou Nuoda Machinery Co., Ltd.

[0052] SDD-A500 / 1200 high-speed bag making machine Shandong Zhaoyuan Plastic Printing and Packaging Machinery Factory.

[0053] 1) Nanocomposite powder

[0054] The nanocomposite powd...

Embodiment 2

[0066] Use low-density linear polyethylene (Qilu Branch of China Petrochemical Corporation, model: 7042) and low-density polyethylene (Qilu Branch of China Petroleum and Chemical Corporation, model: TN26) according to the mass ratio of 3:1 Mixing, carrying out blown film and bag making with the same specifications as the nano-packaging material, and making ordinary fresh-keeping film.

[0067] 1. Determination of physical properties

[0068] According to the test method in GB10457-2009 "Plastic self-adhesive plastic wrap for food", the physical properties of the nanocomposite plastic wrap are tested. The test indicators include tensile strength, nominal strain at break, light transmittance, right-angle tear strength, and oxygen permeability. Rate, carbon dioxide permeability, moisture permeability, self-adhesive and anti-fog. Results Table 1 shows that the mechanical toughness and strength of the nanocomposite plastic wrap have been greatly improved compared with the ordinary...

Embodiment 3

[0077] The packaging application of nanocomposite packaging materials to shiitake mushrooms and the effect of inhibiting the production of endogenous formaldehyde.

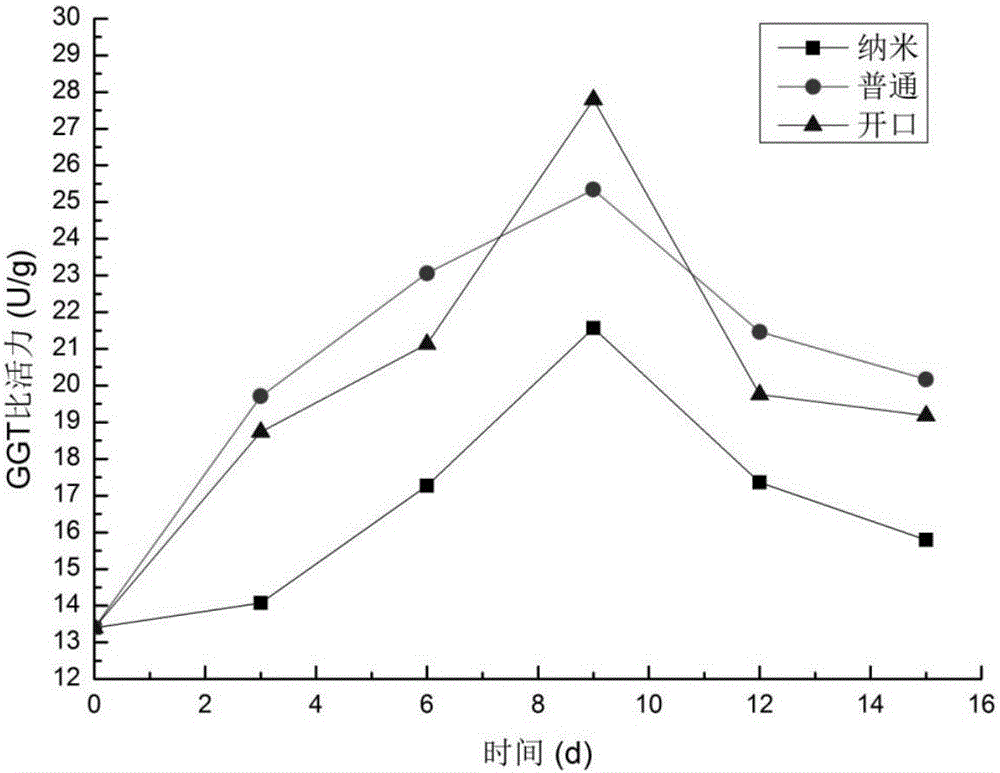

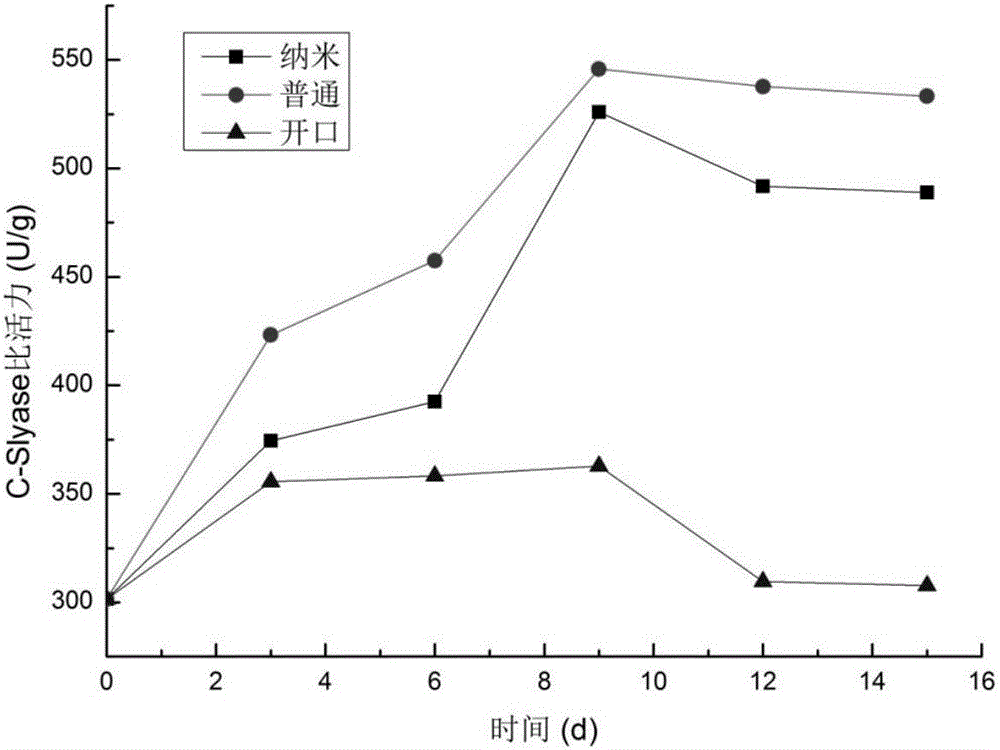

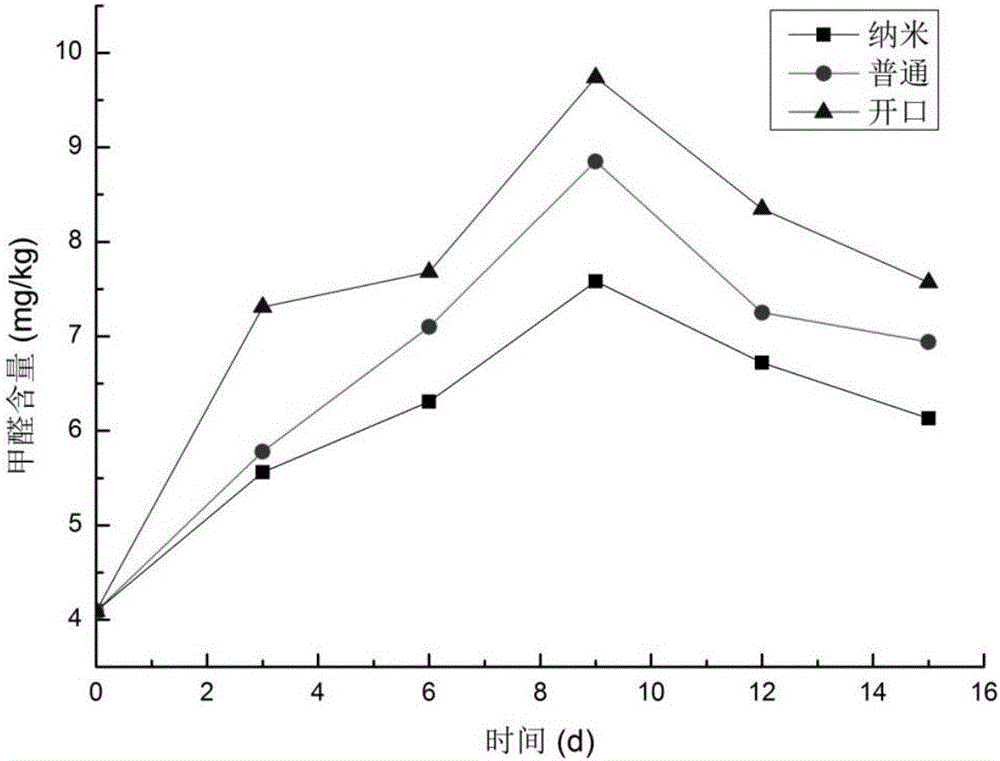

[0078] Select freshly harvested shiitake mushrooms that are free from diseases and insect pests, and cut off inedible mycelia and cultures. Place the shiitake mushrooms in a cold storage at 4°C for 24 hours, and select shiitake mushrooms with basically the same size and no mechanical damage for packaging. The packaging bags are nano-composite packaging bag sealed packaging and ordinary packaging bag sealed packaging respectively. The opening treatment of ordinary packaging bags is used as a comparison. The specifications of the three bags are 40cm long, 15cm wide, and 70cm high. Each bag contains 150g of shiitake mushrooms. Store at 4°C for 15 days. Because the mushroom cap is the main edible part of shiitake mushrooms, and the activities of GGT and C-Slyase enzymes directly affect the content of formaldehyde, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com