Automatic crimping device and press-fitting method for fusion-matching integrated tray of optical fiber distribution frame

A technology of optical fiber distribution frame and crimping device, which is applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as time-consuming and labor-intensive, improper installation of adapters, and inaccurate control of the focus point, so as to avoid damage and reduce Effects on labor costs, increased productivity and assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

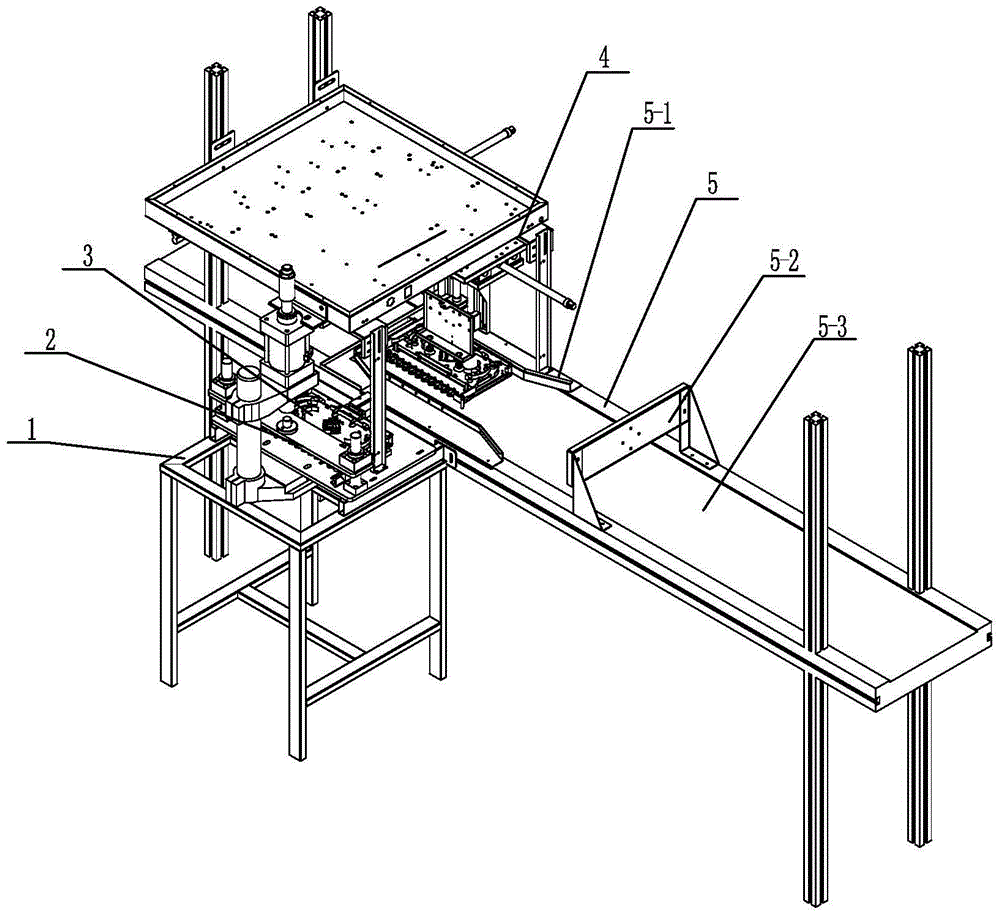

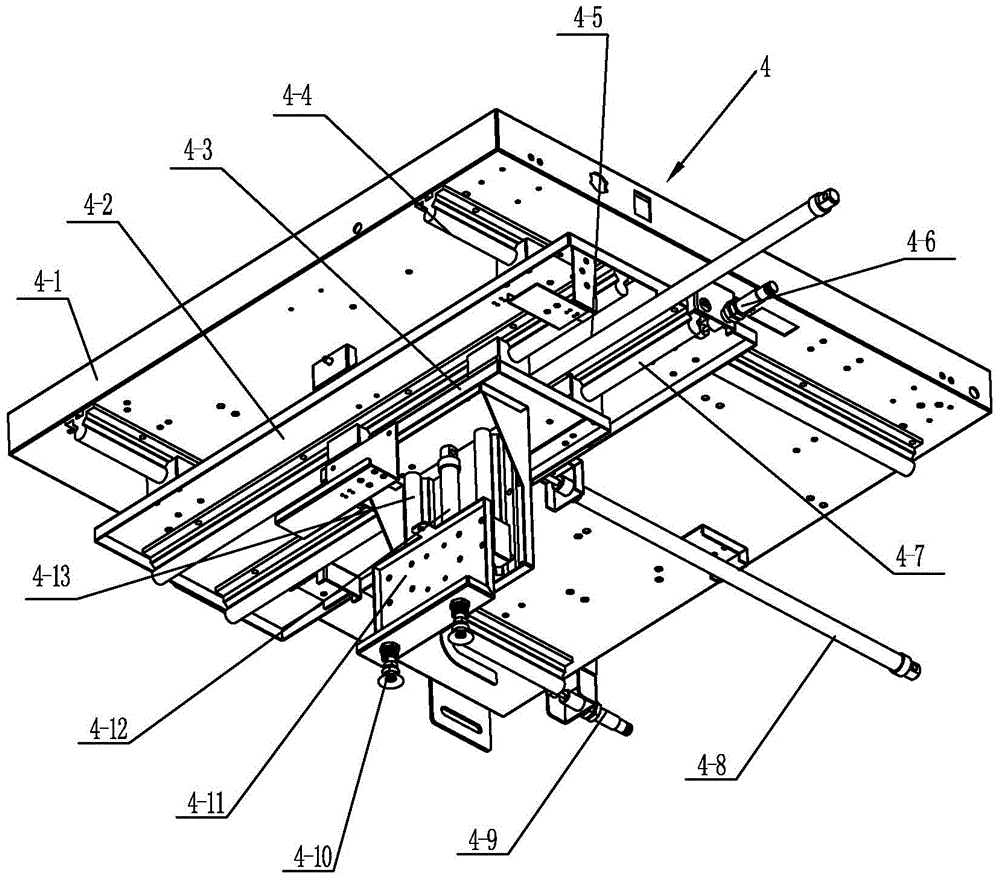

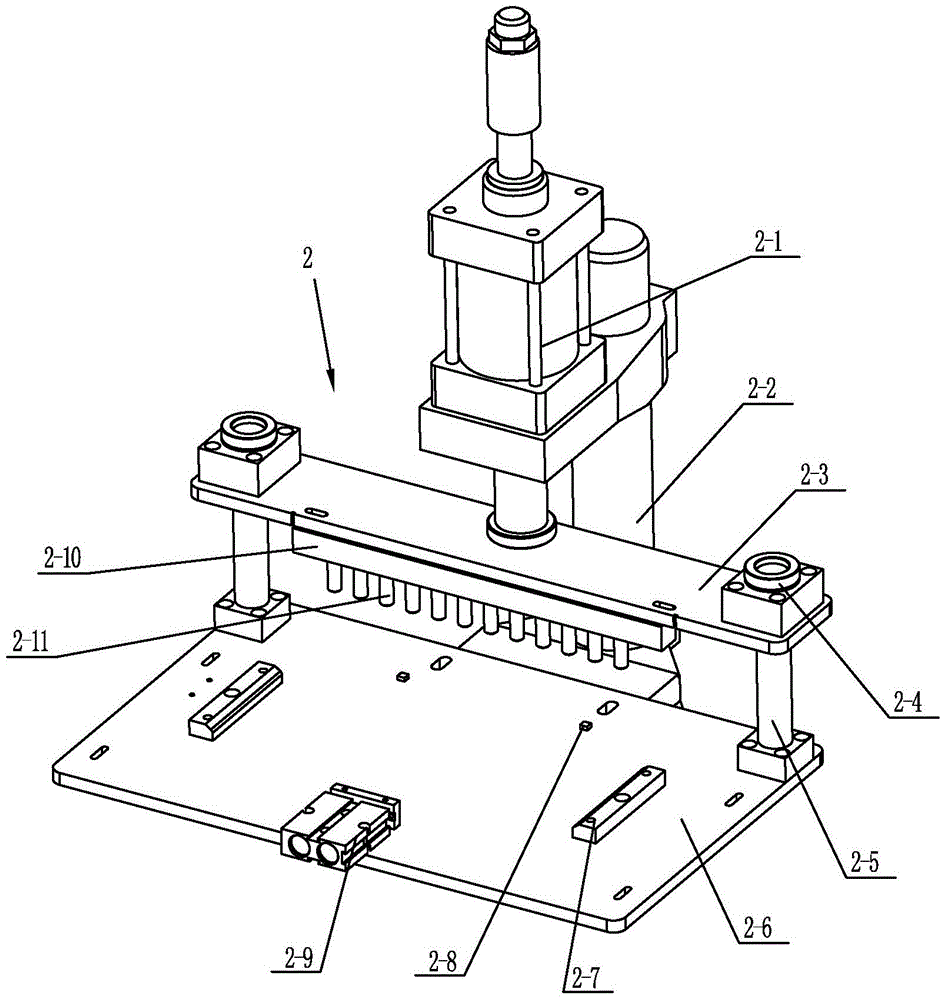

[0021] See figure 1 As shown, the automatic crimping device of the optical fiber distribution frame of the present invention includes a frame 1 , a feeding mechanism 4 , a crimping mechanism 2 and a conveying mechanism 5 . The conveying mechanism 5 of the present invention includes a conveying frame, a motor installed on the conveying frame, and a transmission mechanism. The conveying frame of the present invention can be connected to the frame 1, or set independently. The first position sensor of the integrated disk 3, the position sensor adopts a photoelectric sensor and a travel switch, etc., and the transmission mechanism includes a driving wheel, a driven wheel and a conveyor belt 5-3 installed on the conveyor frame, and the conveyor belt 5-3 is installed on the driving wheel. On the wheel and the driven wheel, the motor drives the driving wheel to drive the conveyor belt 5-3 to move forward. See figure 1 As shown, a guide plate 5-1 is installed on the conveying frame o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com