Reaction device, and vanillin production equipment and production method

A reaction device and technology of vanillin, applied in chemical methods, feeding devices, chemical instruments and methods for reacting liquids with liquids, etc., can solve problems affecting the selectivity of condensation reactions, complex condensation reactions, and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

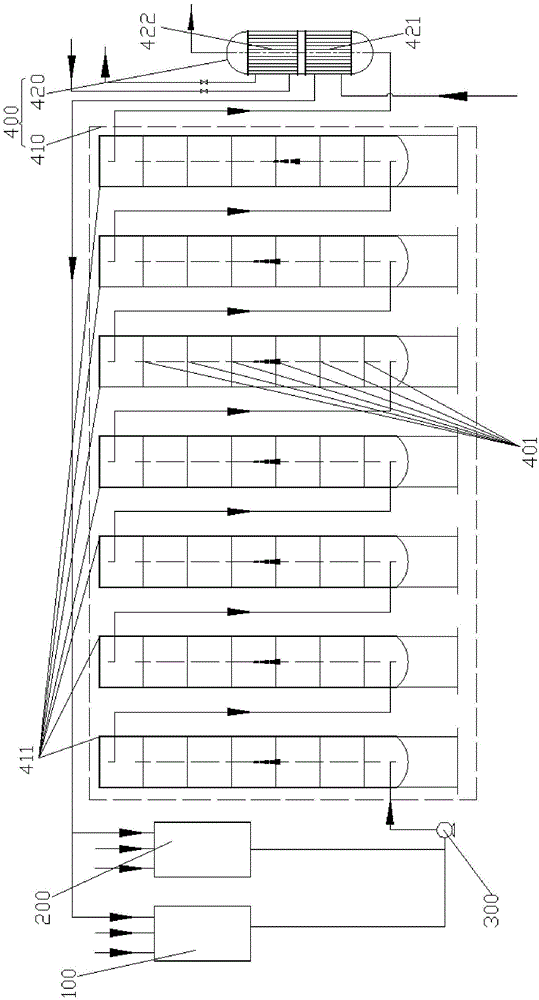

[0056] In the third embodiment, the diameter of the reaction tower is still 2 meters, but the sieve plate 401 is a circular plate with a diameter of 1.2 meters, and the through holes are evenly arranged on the sieve plate 401 . The center of the sieve plate 401 is located on the centerline of the reaction tower 411 , and there is a distance of 0.4 meters between the periphery and the inner wall of the reaction tower 411 .

[0057] When adopting the vanillin production equipment that embodiment three provides and the vanillin production method that above-mentioned embodiment provides, the production data that obtains is as follows:

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com