A kind of tobacco additive derived from fresh tobacco leaves and its preparation method and application

A technology of fresh tobacco leaves and additives, applied in the field of cigarette flavors and fragrances, can solve the problems of inability to alcoholize tobacco leaves, long purification cycle, occupying warehouse space and human resources, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

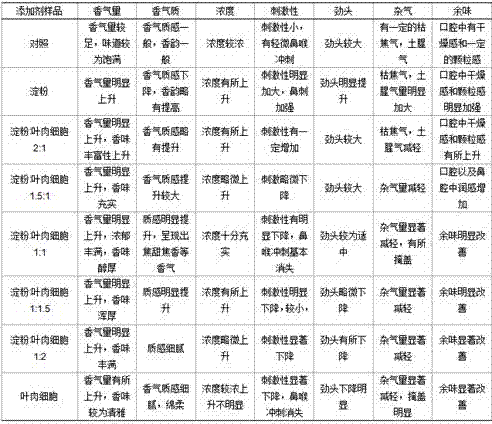

Examples

Embodiment 1

[0052] A method for preparing a tobacco additive derived from fresh tobacco leaves includes the following steps:

[0053] Pick the mature middle tobacco leaves, wash the surface of the tobacco leaves and remove the main veins of the tobacco leaves, and then mix the tobacco leaves from which the main veins have been removed with a phosphate buffer solution at a temperature of 6°C in a mass-volume ratio of 1:8 to obtain a mixture; the phosphoric acid The pH of the buffer is 7, and the concentration is 0.03M;

[0054] Afterwards, the mixture is crushed by a crusher at 6°C until the diameter of the crushed residue is less than 2mm;

[0055] The crushed mixture is filtered through 5 layers of sterile gauze and the residue is discarded. The filtrate is filtered and concentrated with a 0.22um hollow fiber column, and concentrated to 18% of the original volume;

[0056] Then the concentrate is naturally settled at 3°C for more than 10 hours until it is divided into 3 layers. The middle laye...

Embodiment 2

[0060] A method for preparing a tobacco additive derived from fresh tobacco leaves includes the following steps:

[0061] Pick the mature middle tobacco leaves, wash the surface of the tobacco leaves and remove the main veins of the tobacco leaves, and then mix the tobacco leaves with the main veins removed with a phosphate buffer solution at a temperature of 10°C in a mass-volume ratio of 1:8 to obtain a mixture; the phosphoric acid The pH of the buffer is 7, and the concentration is 0.05M;

[0062] Afterwards, the mixture is crushed by a crusher at 10°C until the diameter of the crushed residue is less than 2mm;

[0063] The crushed mixture is filtered through 5 layers of sterile gauze and the residue is discarded. The filtrate is filtered and concentrated with a 0.22um hollow fiber column, and concentrated to 22% of the original volume;

[0064] Then the concentrate is naturally settled at 8°C for more than 8 hours until it is divided into 3 layers. The middle layer material and th...

Embodiment 3

[0068] A method for preparing a tobacco additive derived from fresh tobacco leaves includes the following steps:

[0069] Pick the mature middle tobacco leaves, wash the surface of the tobacco leaves and remove the main veins of the tobacco leaves, and then mix the tobacco leaves with the main veins removed with a phosphate buffer solution at a temperature of 4°C in a mass-volume ratio of 1:12 to obtain a mixture; the phosphoric acid The pH of the buffer is 7, and the concentration is 0.01M;

[0070] Afterwards, the mixture is crushed by a crusher at 4°C until the diameter of the crushed residue is less than 2mm;

[0071] The crushed mixture is filtered through sterile gauze and the residue is discarded. The filtrate is filtered and concentrated with a 0.22um hollow fiber column, and concentrated to 20% of the original volume;

[0072] Then the concentrate is naturally settled at 4°C for more than 5 hours, and then it is divided into three layers by natural settlement. The middle laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com