Dry-wet circulating direct shear device for structural surface of rock mass

A dry-wet cycle and structural surface technology, which is applied to instruments, scientific instruments, and the use of stable shear force to test the strength of materials, etc., can solve disturbances, cannot achieve saturated shear, and cannot obtain dry-wet cycle shear mechanics nature and other issues to achieve the effect of improving connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, and the content of the present invention is not limited to the following embodiments.

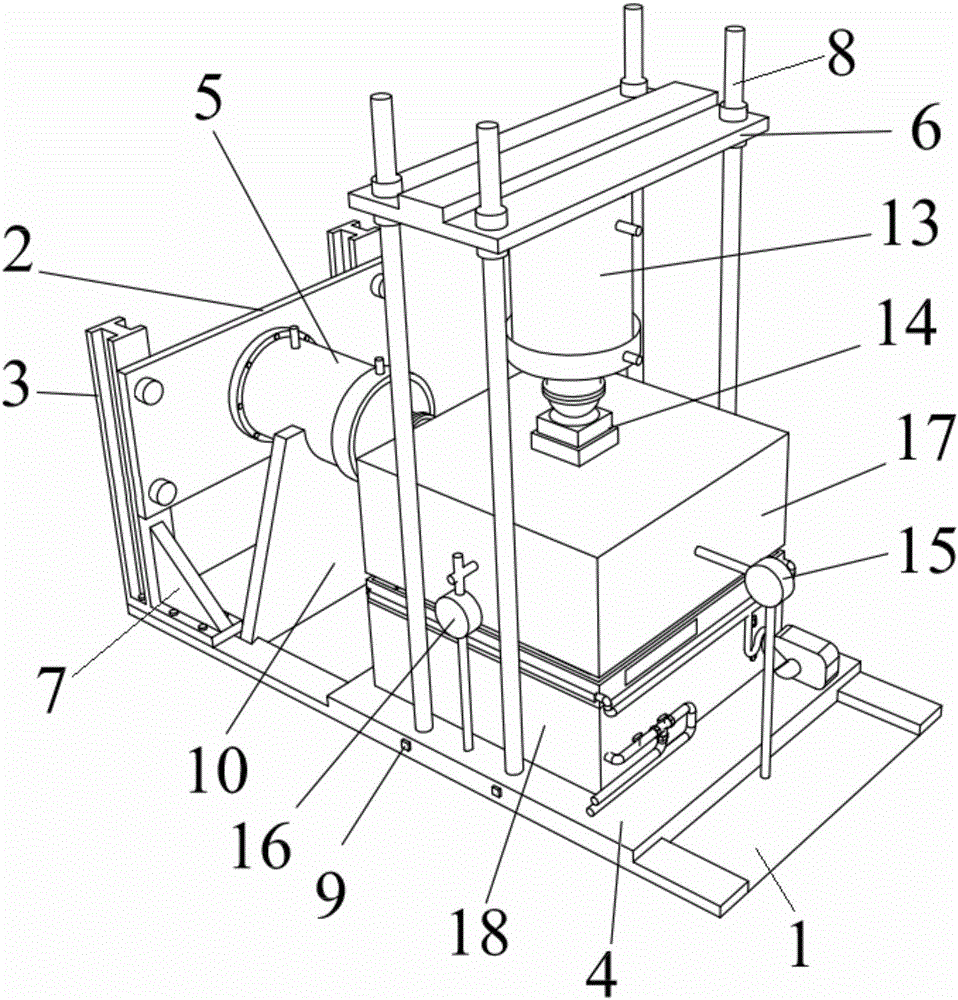

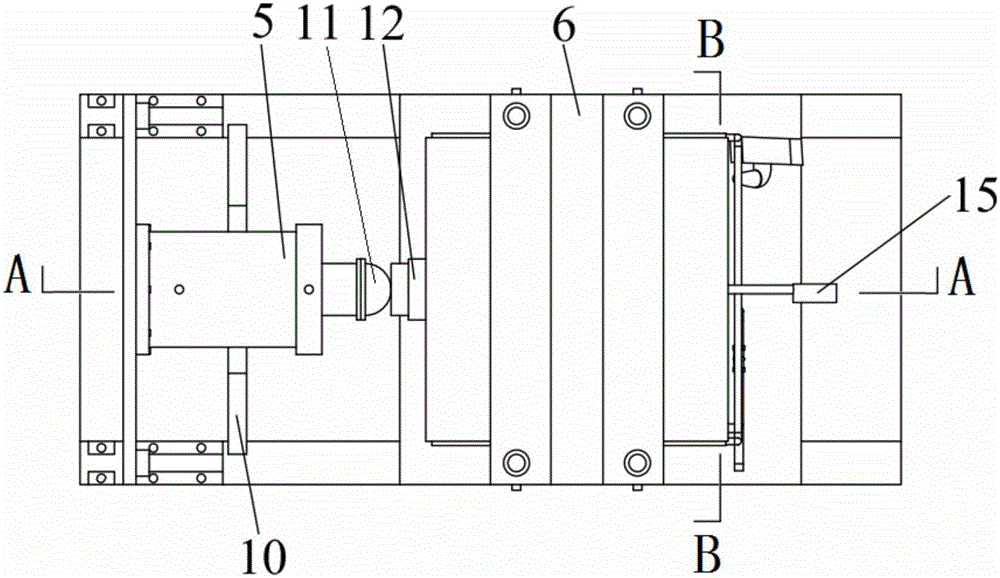

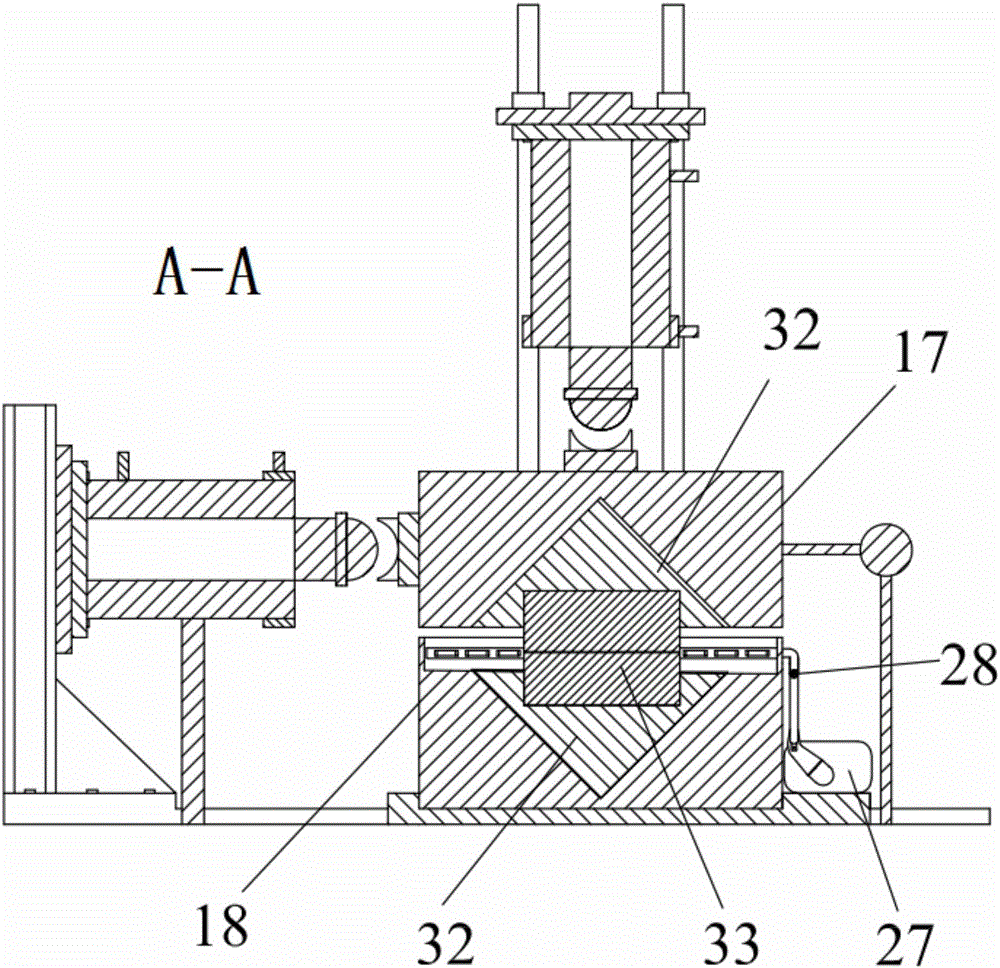

[0027] The dry-wet cycle direct shear instrument for the rock mass discontinuity surface provided by the present invention has a structure such as figure 1 shown, including rack, shear box unit and loading unit;

[0028]The frame includes a base 1 and a horizontal reaction frame, a horizontal jack guide support 10 and a vertical reaction frame installed sequentially on the base 1 along the horizontal direction; the middle part of the base 1 is provided with a square frame 4, and the bottom The shear box 18 is fixed in the square frame 4; the horizontal reaction frame includes a horizontal pressure bearing plate 2, a cantilever column 3 and a reinforcement element 7, the section of the cantilever column 3 is "I" type, and the cantilever column is installed on the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com