Testing device for rock three-axis external pressure and hole internal hydraulic pressure coupling loading and unloading

A technology of hydraulic coupling and test device, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problem of easy intrusion into rock pores or micro-cracks, and even seepage from rock samples, and cannot simulate excavation and surrounding rock unloading. It can solve the problems of load response process and difficult to achieve strong unloading of various stress paths, so as to achieve the effects of simple operation, low manufacturing and experimental costs, and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

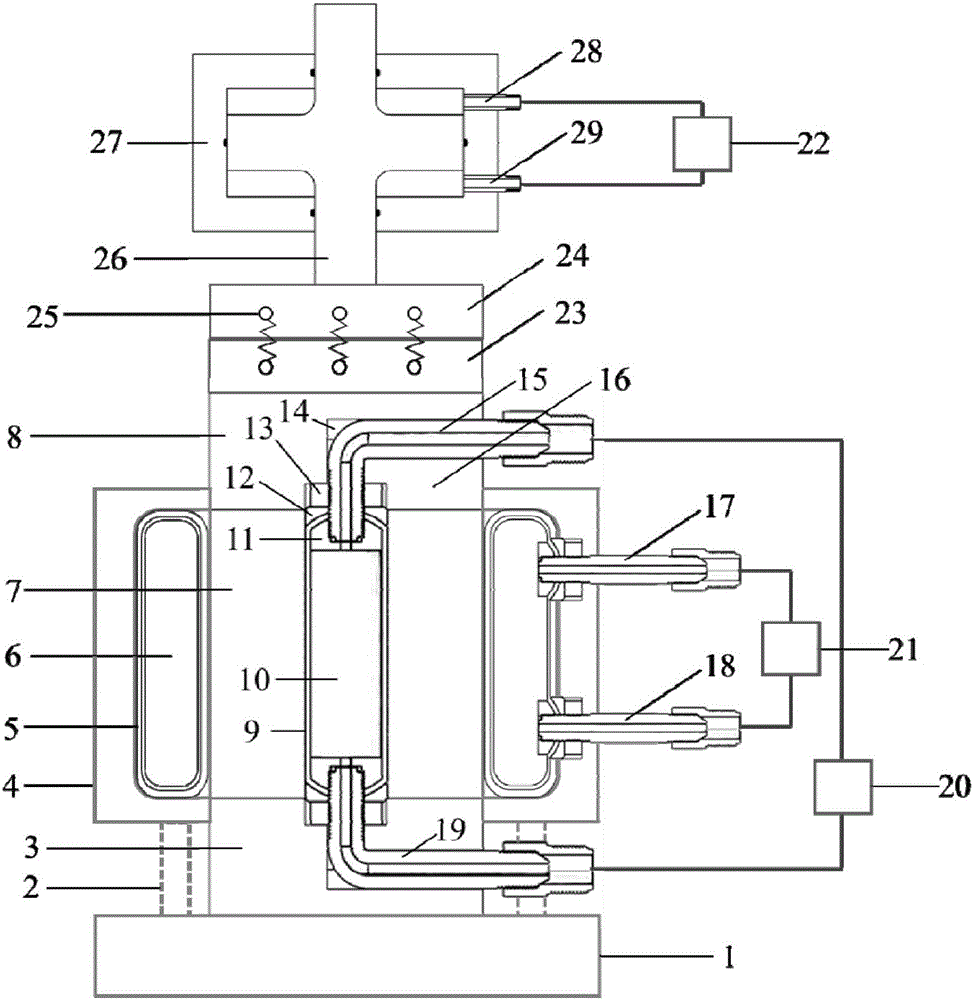

[0037] Below in conjunction with accompanying drawing, the present invention is further described, see accompanying drawing.

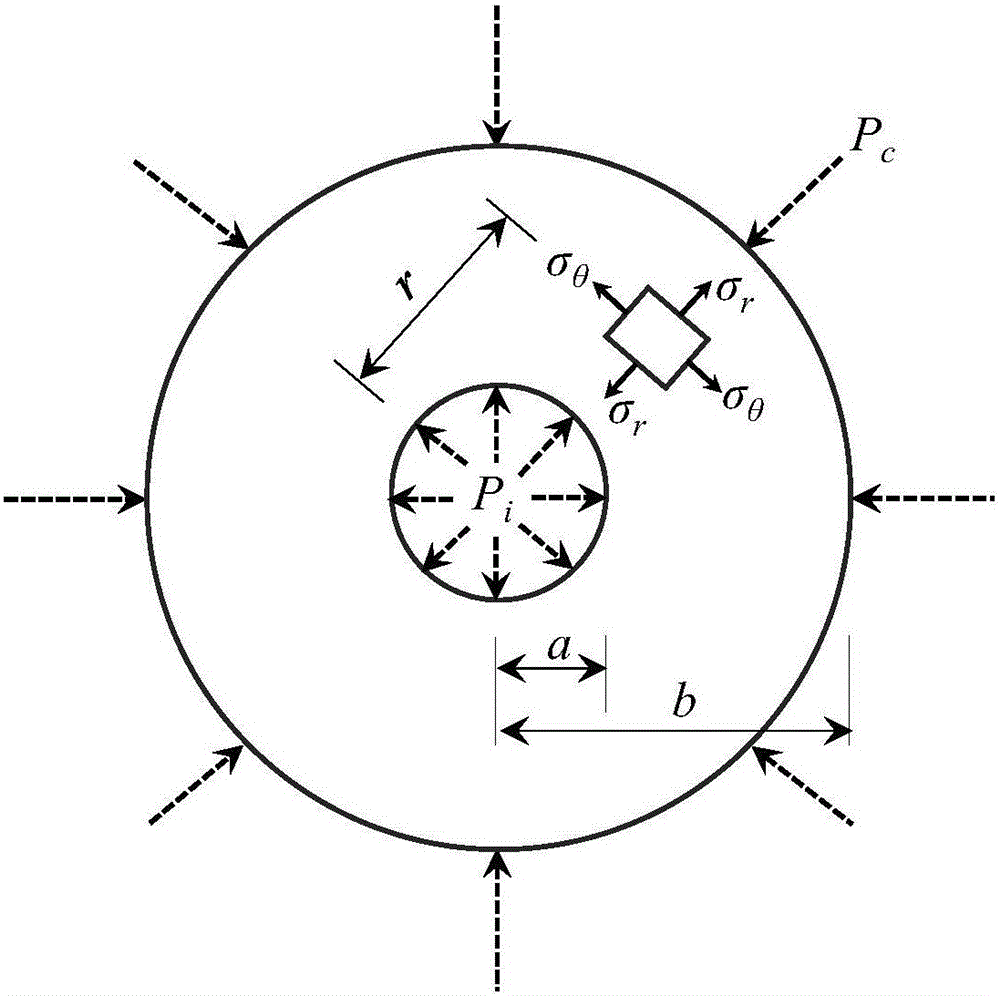

[0038] The invention relates to a rock triaxial external pressure and hole hydraulic coupling loading and unloading test device, which mainly includes four parts: a base, a confining pressure loading and unloading system, an in-hole hydraulic loading and unloading system, and an axial pressure loading and unloading system.

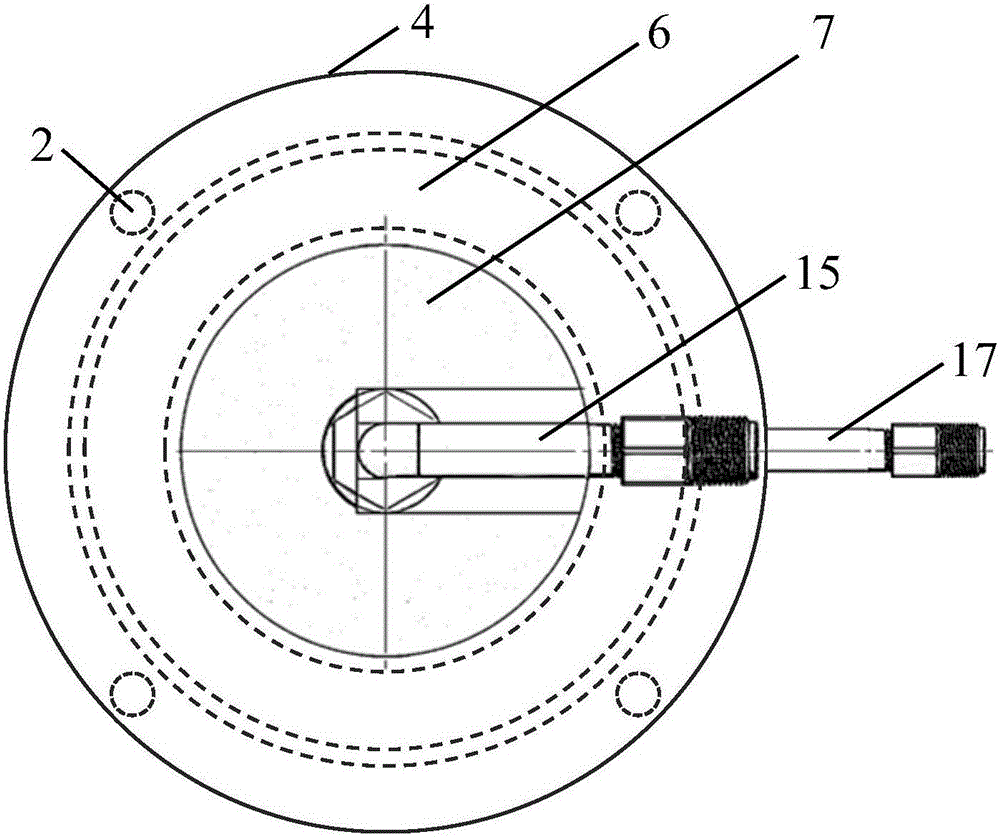

[0039] The base includes a base plate 1 for supporting the hydraulic loading and unloading system in the hole and four cylindrical pillars 2 for supporting the confining pressure loading and unloading system.

[0040] The confining pressure loading and unloading system consists of a pressure chamber 4, a confining pressure bag 6 for storing the hydraulic oil of the confining pressure loading and unloading system, and a confining pressure bag installed between the confining pressure bag 6 and the inner wall of the pressure chamber 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com