Motive power machine closed loop inclinable polygonal excitation gear box testbed

A power machinery and polygonal technology, applied in the field of rail vehicle drive train parameter detection test platform, can solve problems such as energy waste, gearbox shell cracking, bearing cracking, etc., to ensure rationality and accuracy, and reduce structural complexity , the effect of reducing power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is described in detail below in conjunction with accompanying drawing:

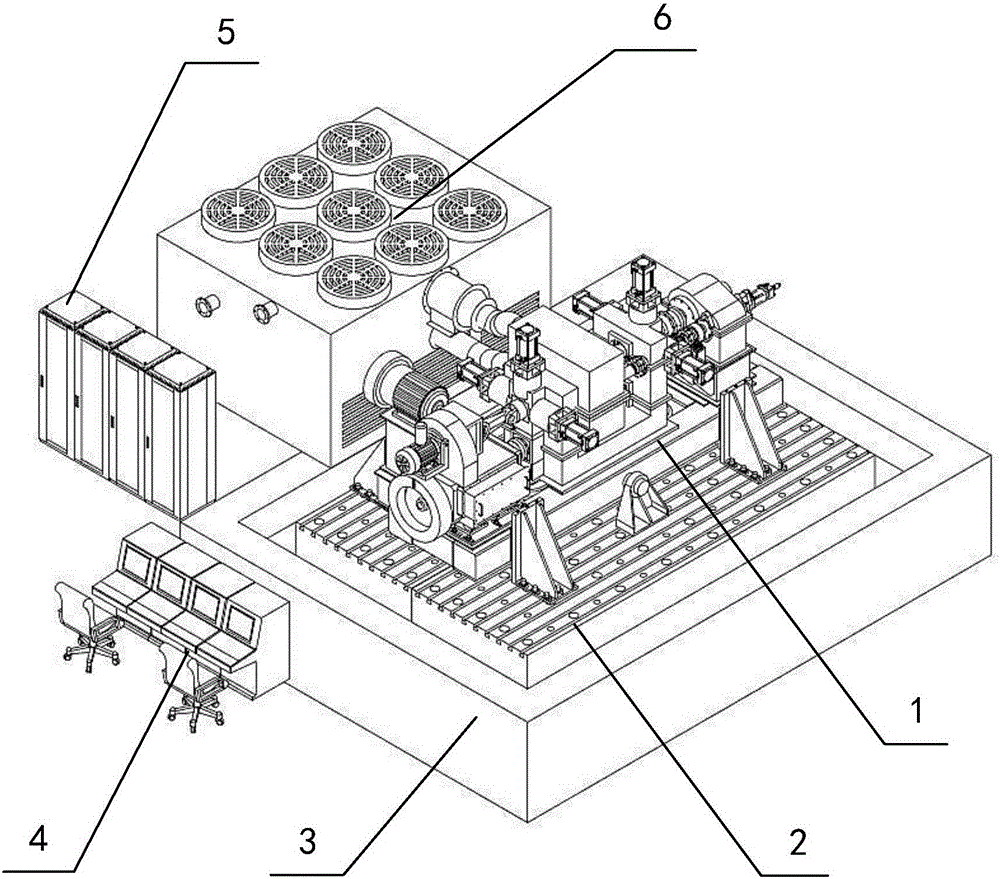

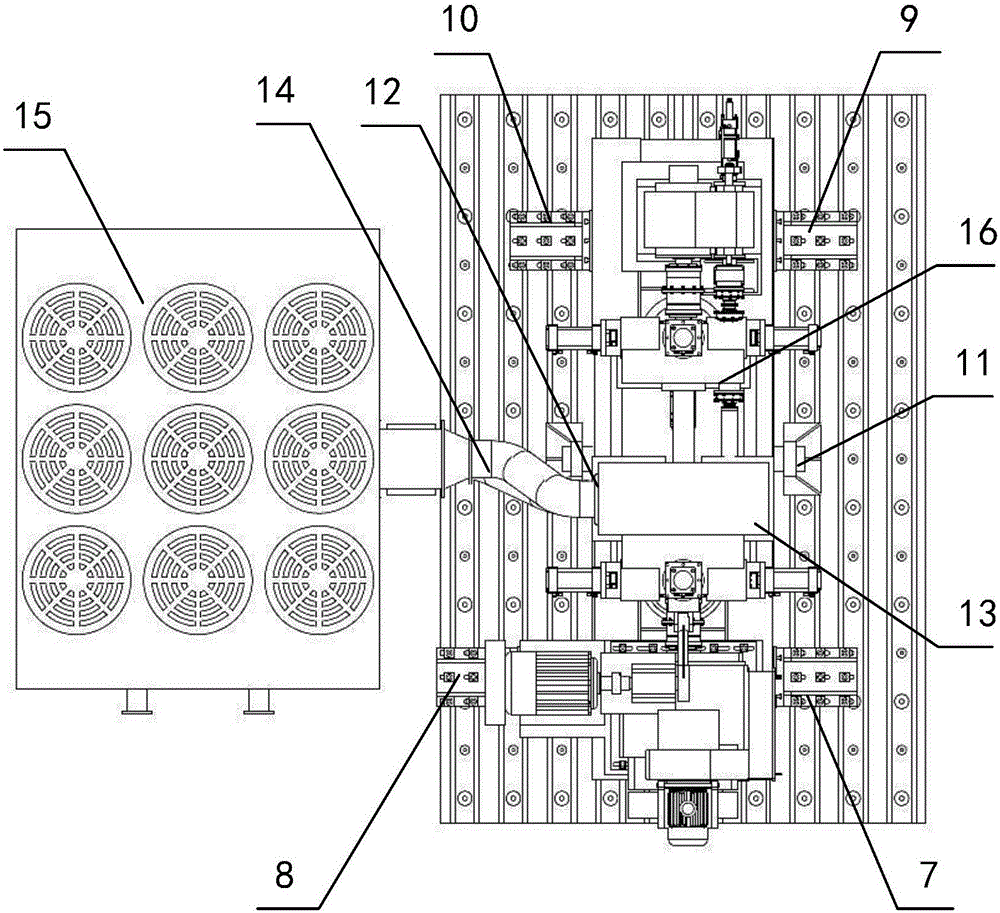

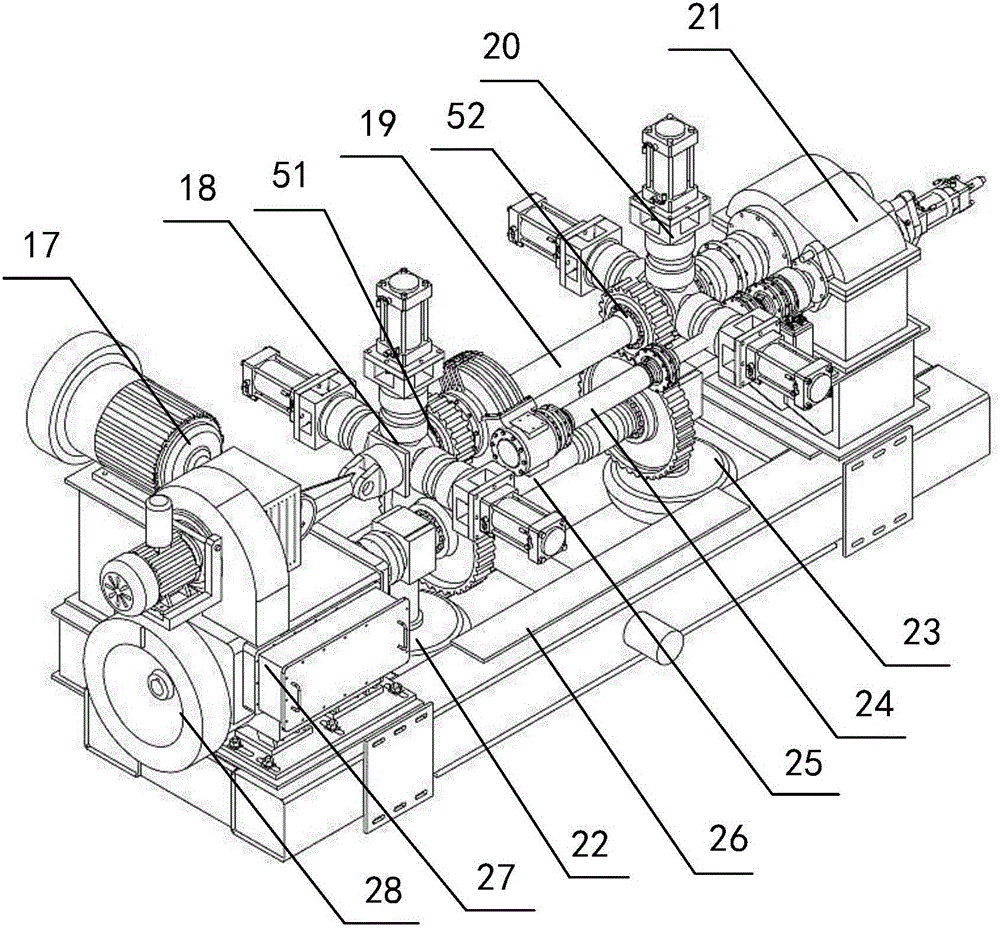

[0048] The power machinery closed-loop tiltable polygonal excitation gearbox test bench of the present invention adopts polygonal excitation to simulate the working environment of the gearbox in the actual operation of the train, and solves the problem that it is difficult to conduct reliability tests on the gearbox under the actual working conditions of rail vehicles. The problem is to meet the reliability detection of rail vehicles under various operating conditions. The power machinery closed-loop tiltable polygonal excitation gearbox test bench uses cylindrical gears to simulate the polygonal wheels and uneven wheel-rail contact surfaces in actual operation, and uses the mechanical impact of the gears to vertically excite the axle of the gearbox under test. At the same time, the electric eccentric cam mechanism of the motor is used to axially vibrate the axle of the tested...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com