Multi-segment temperature sensor and preparation method thereof

A temperature sensor and sensor technology, applied to thermometers, thermometers and instruments using directly heat-sensitive electric/magnetic elements, can solve the problems of high cost, troublesome layout, poor reliability, etc., to achieve simple layout and reduce construction difficulty and cost, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described below in conjunction with the accompanying drawings.

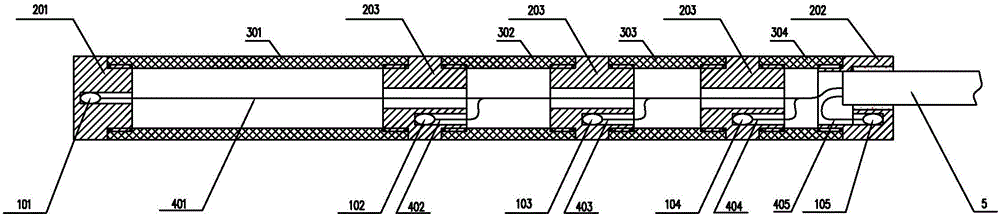

[0026] The invention discloses a multi-section temperature sensor, which includes more than two thermistors and sensor seats corresponding to each thermistor, and also includes a hollow spacer made of temperature isolation material, and each thermistor is arranged on the In the corresponding sensor seats, the sensor seats are arranged side by side at intervals, and the adjacent sensor seats are connected through spacers, and the output signal lines of each thermistor are merged through the hollow parts of the sensor seats and the spacers and finally connected from the sensor at one end. seat leads.

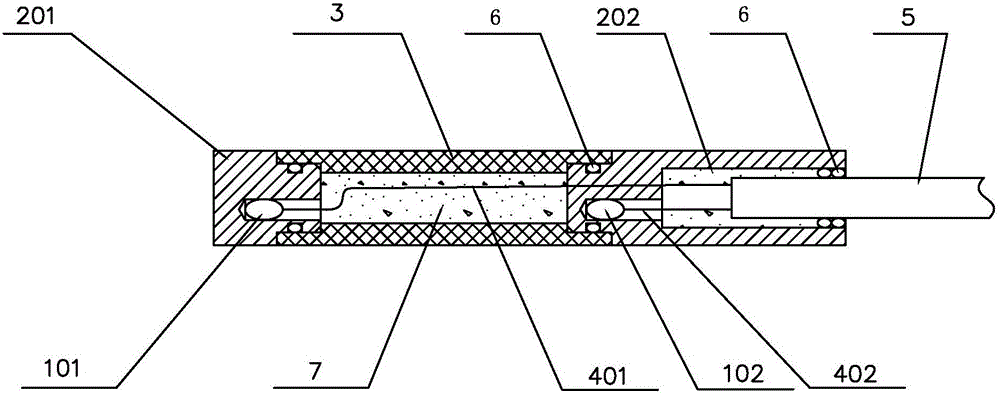

[0027] The thermistor in the multi-section temperature sensor of the present invention can adopt two according to actual needs, as figure 1The first preferred structure shown includes two thermistors: the first thermistor 101 and the second thermistor 102, and two sensor seats re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com