Large air volume composite muffler

A technology of muffler and large air volume, applied in muffler devices, machines/engines, engine components, etc., can solve the problems of small channel area, large thickness of inserts, and unsatisfactory noise reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

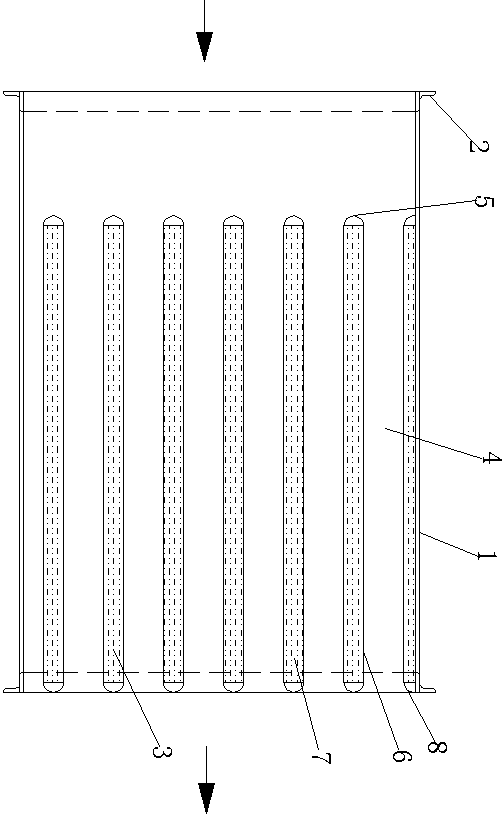

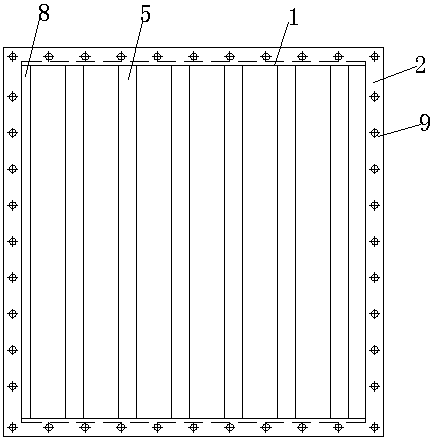

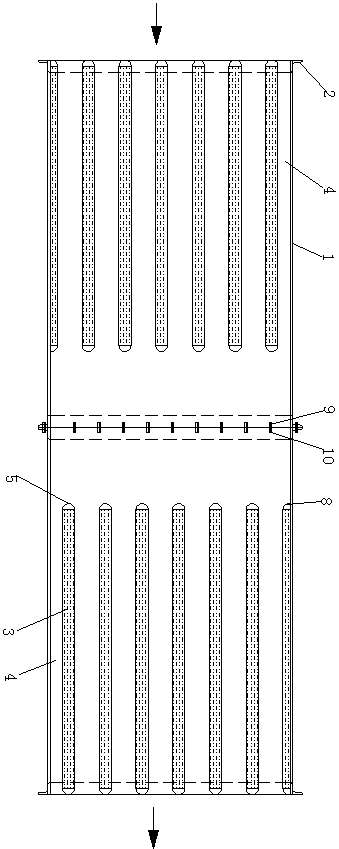

[0105] exist figure 1 , 2 In the first embodiment shown, a large air volume and high-efficiency composite muffler is composed of a straight-pipe muffler shell (1), two-end flanges (2), muffler inserts (3) and an airflow channel (4) , the inner wall of the muffler shell (1) is not provided with sound-absorbing material; the muffler inserts (3) are A muffler insert (3), B muffler insert (3), B The thickness of the insert (3) is 1 / 2 of the thickness of the A muffler insert (3), and several pieces of A muffler inserts (3) and one piece of B muffler inserts ( 3), the airflow channel (4) between the muffler inserts (3) is consistent, and the airflow channel (4) between the side of the muffler shell (1) and the A muffler insert (3) is the muffler insert (3) 1 / 2 of the airflow channel (4) between ); the length of the muffler insert (3) is 80% of the length of the muffler shell (1), and the muffler insert (3) is close to the muffler flange (2) Installed at one end.

[0106]The thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com