Mechanical gripping anchor for carbon fiber plate and reinforcing device

A technology of carbon fiber boards and reinforcement devices, which is applied in the direction of building reinforcements, structural elements, building components, etc., can solve problems such as bonding and falling off, and achieve the effects of uniform force, shortening the construction period, and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example of Mechanical Clamping Anchor for Carbon Fiber Plate

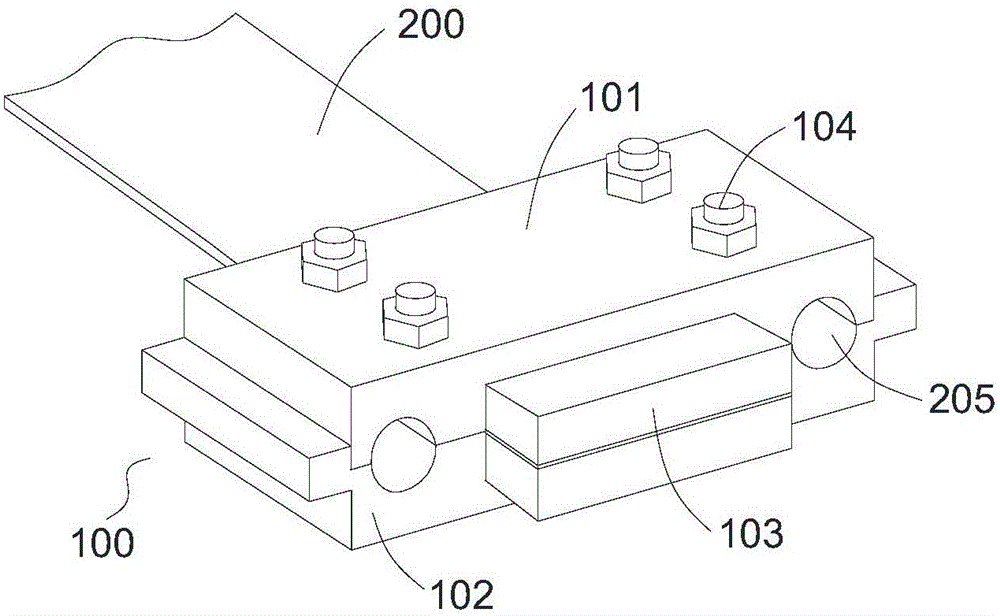

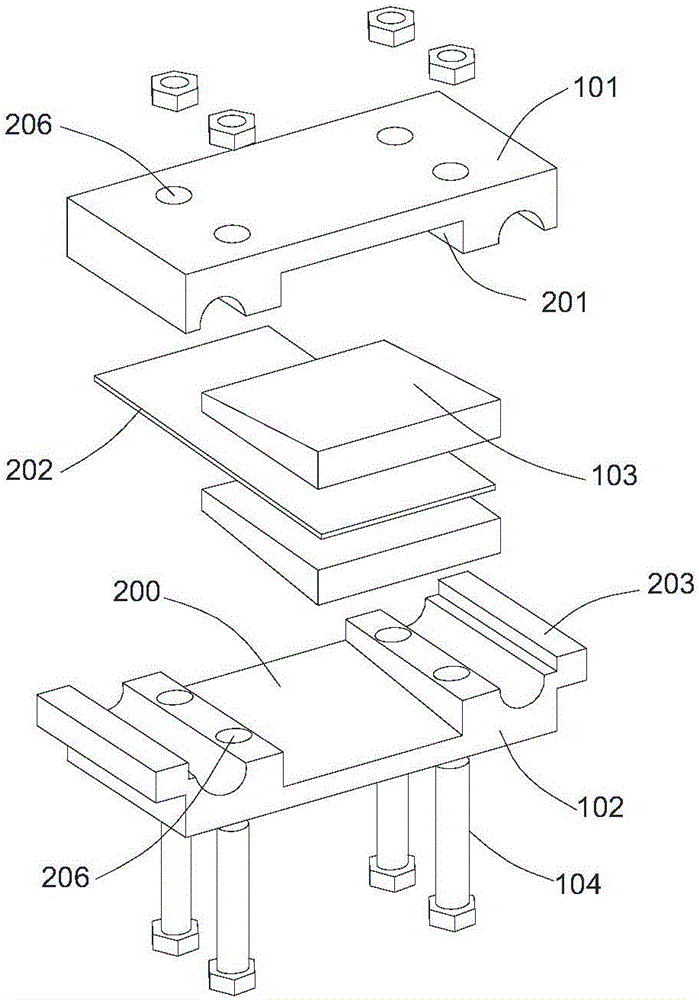

[0048] see Figure 1-2 , the embodiment of the present invention provides a carbon fiber plate mechanical clamping anchor, including an anchor unit 100 .

[0049] The anchor unit 100 is used to clamp the carbon fiber plate 200. When in use, the carbon fiber plate 200 is clamped on the two anchor units 100, and the two anchor units 100 realize the tension of the carbon fiber plate 200, and the carbon fiber plate 200 has tension. Prestressed, able to withstand external compressive stress, and then realize its function. Therefore, two anchor units 100 are provided, and each anchor unit 100 is clamped at one end of the carbon fiber plate 200 , and the two anchor units 100 are arranged opposite to each other, thereby realizing the tension of a carbon fiber plate 200 . In actual processing, the carbon fiber plate 200 is set as a rectangular plate. The rectangular plate has two opposite plate surfaces and two set...

Embodiment 2

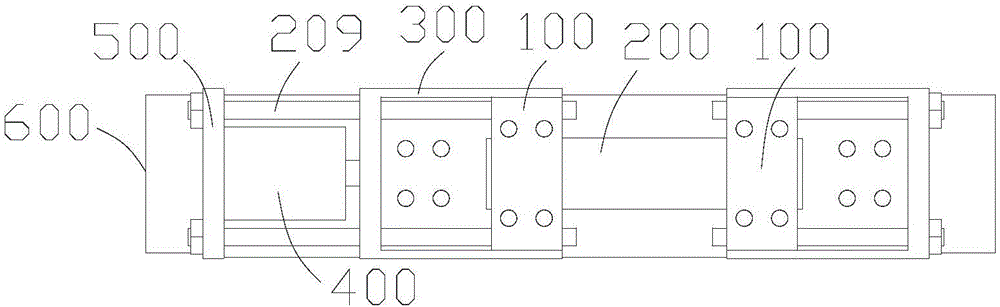

[0061] Example of a reinforcement device

[0062] see Figure 3-6 , this embodiment provides a reinforcement device, including the carbon fiber plate mechanical clamping anchor of embodiment 1, a carbon fiber plate 200 , a jack 400 , a tension baffle 500 and two fixing devices 300 arranged in pairs.

[0063] The fixing device 300 is used to fix the anchor on the object to be reinforced. In this embodiment, the steel beam 600 is taken as an example, and the reinforcing device is used to strengthen the steel beam 600 . There are two fixing devices 300, and each fixing device 300 corresponds to one anchor unit 100, and the anchor unit 100 can slide in the corresponding fixing device 300, that is, after the two anchor units 100 fix the carbon fiber plate 200, the anchor The anchor unit 100 is installed on the corresponding fixing device 300. By adjusting the positions of the anchor unit 100 and the fixing device 300, the tension of the carbon fiber plate 200 is realized. The tens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com