Blocking valve, grouting sleeve and prefabricated component connecting method

A grouting and sleeve technology, which is applied to building components, valve shell structures, lift valves, etc., can solve problems such as the inability to ensure the saturation of the cavity slurry, and the inability to evaluate the effect of sleeve grouting, so as to improve construction efficiency and strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

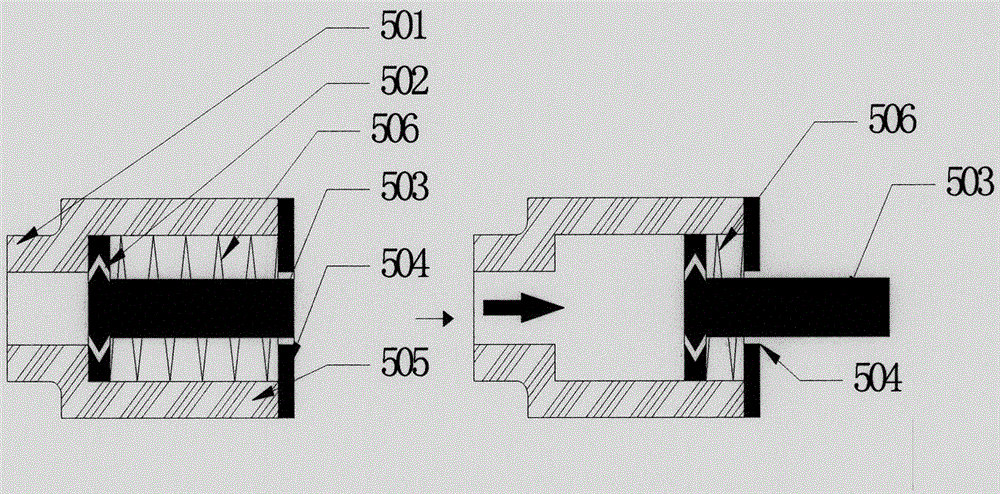

[0041] Example 1 see image 3 , image 3 Shown is the blocking valve 5 whose blocking body is a T-shaped blocking body 503 . The figure on the left shows the initial state of the check valve, the figure on the right shows the state of the check valve when it is filled with slurry, and the arrow at the connection end 501 in the figure on the right indicates the flow direction of the slurry. As shown in the figure, the blocking valve 5 in this embodiment includes a housing 505 , a T-shaped blocking body 503 , and a spring 506 . The casing 505 has a tubular cavity, one end of which extends outward to form a connection end 501 connected to the exhaust hole of the grouting sleeve, and the other end shrinks inward to the casing 505 to prevent the body from sliding out and the filling of the slurry in the tubular cavity can be observed. The limit observation port 504. The T-shaped blocking body 503 is located in the casing 505 between the connecting end 501 and the limit observati...

Embodiment 2

[0042] See Example 2 Figure 4 , Figure 4 Shown is the blocking valve 5 in which the blocking body is a spherical blocking body 507 . The figure on the left shows the initial state of the check valve 5, the figure on the right shows the check valve state when it is filled with slurry, and the arrow at the connection end 501 in the figure on the right indicates the flow direction of the slurry. Compared with the first embodiment, the main difference between this embodiment and the first embodiment is that the shape of the blocking body is different. Since the shape of the blocking body in this embodiment is spherical, it has good moving performance under the push of the slurry pressure. There is no connection between the body and the housing 505. Of course, in the specific implementation, this embodiment can also refer to the first embodiment to set a pressure scale.

Embodiment 3

[0043] See Example 3 Figure 5 , Figure 5 Shown is a blocking valve in which the blocking body is a sheet blocking body 508 . The figure on the left shows the initial state of the check valve, the figure on the right shows the state of the check valve when it is filled with slurry, and the arrow at the connection end 501 in the figure on the right indicates the flow direction of the slurry. The sheet-like blocking body 508 is connected with the inner wall of the casing 505 near the limit observation port 504 through the rotating shaft 509. The process is similar to the opening and closing process of the door. In the initial state, the sheet-like blocking body 508 is located in the cavity of the casing 505. , under the push of the slurry pressure, the sheet-like blocking body 508 rotates around the shaft 509. When the sheet-like blocking body 508 is completely rotated to the opening of the limit observation port 504 (eg Figure 5 Right), indicating that the grouting sleeve is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com