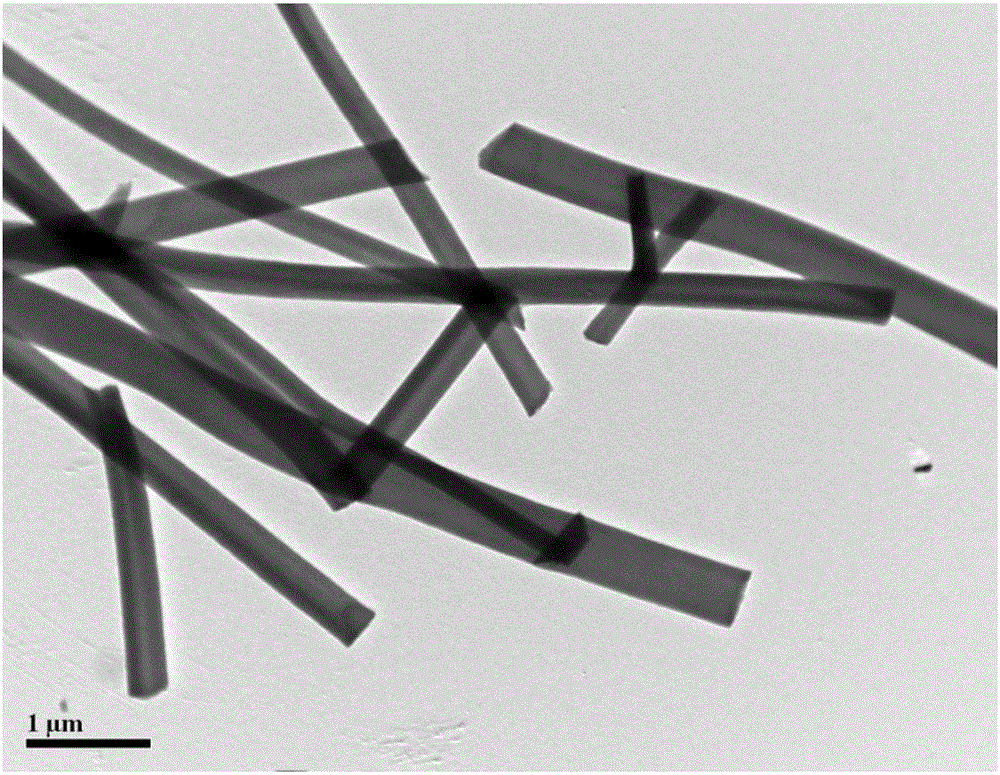

Active carbon nanofiber and preparation method thereof

A nanofiber and activated carbon technology, applied in the field of material science, can solve the problems of large amount of activator, inability to achieve uniform activation, and high cost, and achieve the effect of improving activation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Add 1 g of polyacrylonitrile to 10 g of N,N-dimethylformamide, stir at 60° C. for 2 hours, then cool naturally to obtain a yellow transparent and clear solution.

[0029] (2) Add 0.1 g of phosphorous acid into the above solution, and stir for 2 hours until the phosphorous acid is completely dissolved to obtain an electrospinning precursor liquid.

[0030] (3) The electrospinning method is adopted to prepare polyacrylonitrile nanofibers containing phosphorous acid, and the specific parameters are as follows: the syringe needle used is No. 25, the applied voltage is 20kV, a flat plate collector is adopted, the needle point is 15 cm away from the collector, and the injection speed 1mL / min, spinning time 12 hours.

[0031] (4) The polyacrylonitrile / phosphorous acid nanofibers prepared by the electrospinning method were pre-oxidized at 300° C. for 30 min in an air atmosphere.

[0032] (5) Put the pre-oxidized nanofibers into the atmosphere protection furnace, at 800 ° C...

Embodiment 2

[0036] (1) Add 1 g of polyacrylonitrile to 10 g of N,N-dimethylformamide, stir at 60° C. for 2 hours, then cool naturally to obtain a yellow transparent and clear solution.

[0037] (2) Add 0.05 g of phosphorous acid into the above solution, and stir for 2 hours until the phosphorous acid is completely dissolved to obtain an electrospinning precursor liquid.

[0038] (3) The electrospinning method is adopted to prepare polyacrylonitrile nanofibers containing phosphorous acid, and the specific parameters are as follows: the syringe needle used is No. 25, the applied voltage is 20kV, a flat plate collector is adopted, the needle point is 15 cm away from the collector, and the injection speed 1mL / min, spinning time 12 hours.

[0039] (4) The polyacrylonitrile / phosphorous acid nanofibers prepared by the electrospinning method were pre-oxidized at 300° C. for 30 min in an air atmosphere.

[0040] (5) Put the pre-oxidized nanofibers into the atmosphere protection furnace, at 800 ° ...

Embodiment 3

[0043] (1) Add 1 g of polyacrylonitrile to 10 g of N,N-dimethylformamide, stir at 60° C. for 2 hours and then cool naturally to obtain a yellow transparent and clear solution.

[0044] (2) Add 0.02 g of phosphorous acid into the above solution, and stir for 2 hours until the phosphorous acid is completely dissolved to obtain an electrospinning precursor liquid.

[0045] (3) Adopt electrospinning method to prepare the polyacrylonitrile nanofiber that contains phosphorous acid, concrete parameter is as follows: the syringe needle size that it is packed into adopting is No. 25, and applied voltage is 20kV, and needle point is apart from collector distance 15cm, and injection speed 1mL / min, spinning time 12 hours.

[0046] (4) The polyacrylonitrile / phosphorous acid nanofibers prepared by the electrospinning method were pre-oxidized at 300° C. for 30 min in an air atmosphere.

[0047] (5) Put the pre-oxidized nanofibers into the atmosphere protection furnace, at 1000°C, high-purit...

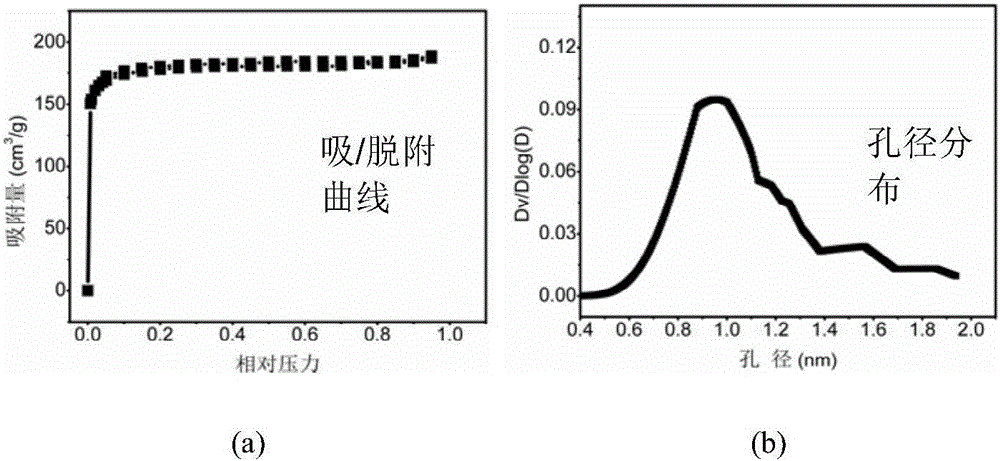

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com