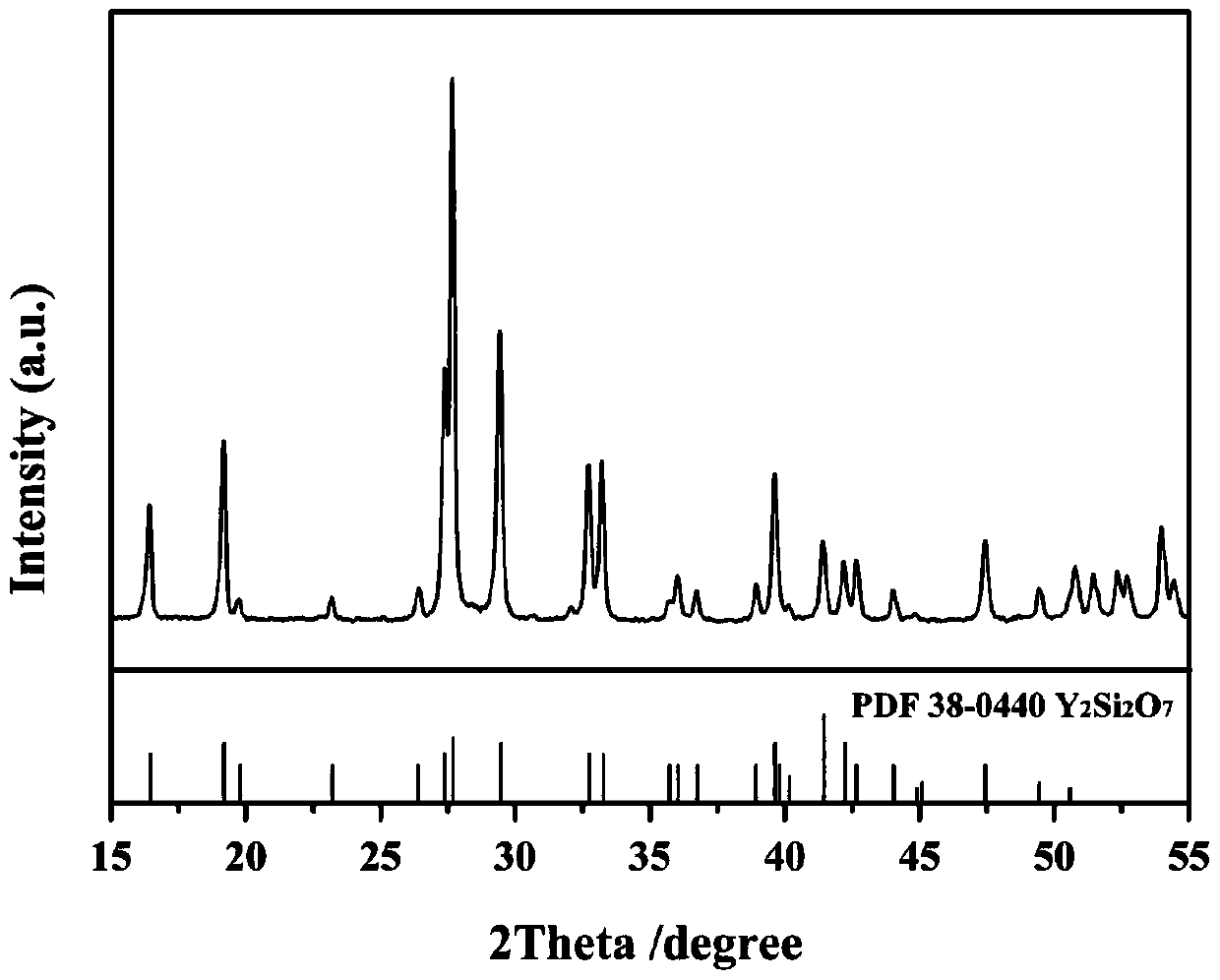

A kind of y2si2o7 whisker and preparation method thereof

The technology of whisker and yttrium silicate is applied in the field of Y2Si2O7 whisker and its preparation, and achieves the effects of improving diffusion rate, easy control, and facilitating the elimination of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] a Y 2 Si 2 o 7 The preparation method of whisker, comprises the following steps:

[0030] (1) Weigh analytically pure Y(NO) 3 ·6H 2 O in a beaker, in a fume hood as Y(NO) 3 ·6H 2 The molar ratio of O:TEOS=1:1 measures certain TEOS, stirs 30min to obtain the mixed solution of the two, then adds a certain amount of dehydrated alcohol, is mixed with the solution that concentration is 0.5mol / L, heats and stirs evenly, obtains Transparent yttrium silicate precursor mixture.

[0031] (2) Place the obtained yttrium silicate precursor mixture in a polytetrafluoroethylene-lined hydrothermal kettle, control the filling ratio to 30%, then put the reaction kettle into an oven, control the temperature at 100°C, and react for 12 hours . A wet gel of yttrium silicate was obtained.

[0032] (3) The obtained yttrium silicate wet gel was dried at 100°C, and then heat-treated in a muffle furnace at 350°C for 60 minutes to obtain yttrium silicate dry gel powder.

[0033] (4) Mix ...

Embodiment 2

[0036] a Y 2 Si 2 o 7 The preparation method of whisker, comprises the following steps:

[0037] (1) Weigh analytically pure Y(NO) 3 ·6H 2 O in a beaker, in a fume hood as Y(NO) 3 ·6H 2 The molar ratio of O:TEOS=1:1 measures certain TEOS, stirs 60min to obtain the mixed solution of the two, then adds a certain amount of dehydrated alcohol, is mixed with the solution that concentration is 0.75mol / L, heats and stirs evenly, obtains Transparent yttrium silicate precursor mixture.

[0038] (2) Place the obtained yttrium silicate precursor mixture in a polytetrafluoroethylene-lined hydrothermal kettle, control the filling ratio to 50%, then put the reaction kettle into an oven, control the temperature at 110°C, and react for 24h . A wet gel of yttrium silicate was obtained.

[0039] (3) The obtained yttrium silicate wet gel was dried at 80°C, and then heat-treated in a muffle furnace at 500°C for 30 minutes to obtain yttrium silicate dry gel powder.

[0040] (4) Mix the o...

Embodiment 3

[0043] a Y 2 Si 2 o 7 The preparation method of whisker, comprises the following steps:

[0044] (1) Weigh analytically pure Y(NO) 3 ·6H 2 O in a beaker, in a fume hood as Y(NO) 3 ·6H 2 O: TEOS = 1: 1 molar ratio Take a certain amount of TEOS, stir for 50 minutes to get a mixture of the two, then add a certain amount of absolute ethanol to prepare a solution with a concentration of 1mol / L, heat and stir evenly to obtain a transparent yttrium silicate precursor mixture.

[0045] (2) Place the obtained yttrium silicate precursor mixture in a polytetrafluoroethylene-lined hydrothermal kettle, control the filling ratio to 60%, then put the reaction kettle into an oven, control the temperature at 120°C, and react for 24h . A wet gel of yttrium silicate was obtained.

[0046] (3) The obtained yttrium silicate wet gel was dried at 90°C, and then heat-treated in a muffle furnace at 400°C for 50 minutes to obtain yttrium silicate dry gel powder.

[0047] (4) Mix the obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com