Method for gathering platinum and palladium in solution

A solution, platinum-palladium technology, applied in the field of separation and recovery of platinum-palladium-containing solution, can solve the problems of poor separation effect, low efficiency, high cost, etc., and achieve the effects of reduced use cost, shortened reaction time, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

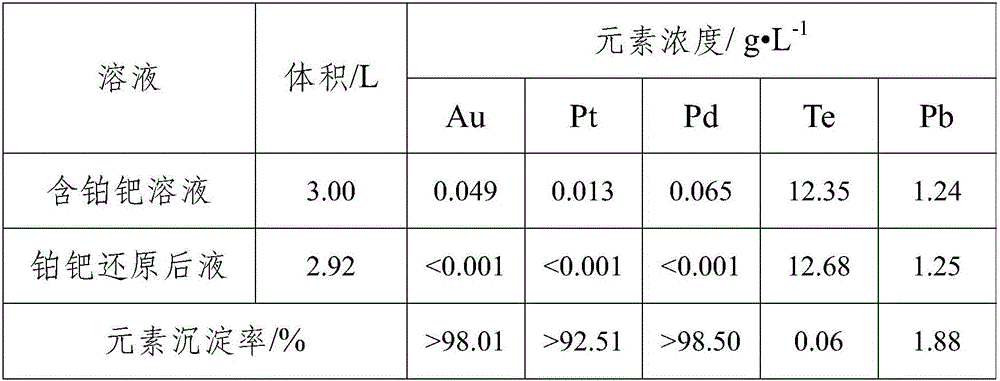

[0018] Accurately measure 3.00L of platinum-palladium-containing solution into a 5L reactor, stir and adjust the solution to acidity, heat up to 75°C, and then add sodium sulfite solution with a concentration of 100g / L to the reaction solution at a rate of 50mL / min In, and monitor the potential of the reaction solution with a potentiometer, stop when the potential of the solution reaches 535mV. After the solution is cooled, the solid and liquid are separated to obtain platinum-palladium-reduced liquid and platinum-palladium concentrate. The volume, main element concentration and precipitation rate of the solution before and after the reaction are shown in Table 1, and the composition of the platinum palladium concentrate is shown in Table 2.

[0019] Table 1 Elemental analysis results before and after platinum palladium solution reduction

[0020]

[0021] Table 2 The element composition analysis results of platinum palladium concentrate

[0022] the element

[...

Embodiment 2

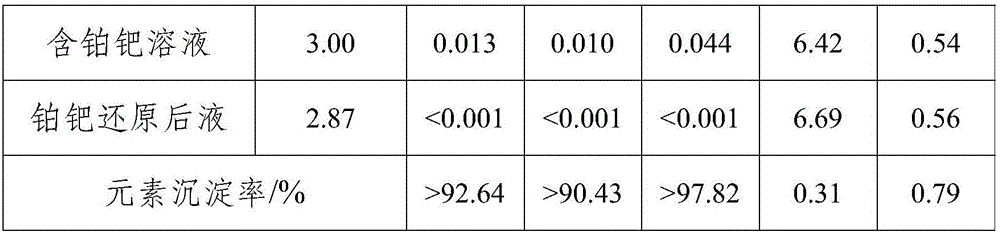

[0025] Accurately measure 3.00L of platinum-palladium-containing solution and pour it into a 5L reactor, stir and adjust the solution to acidity, heat up to 65°C, and then feed SO at a flow rate of 50mL / min 2 Gas, and monitor the potential of the reaction solution with a potentiometer, and stop when the potential of the solution reaches 505mV. After the solution is cooled, the solid and liquid are separated to obtain platinum-palladium-reduced liquid and platinum-palladium concentrate. The volume, main element concentration and precipitation rate of the solution before and after the reaction are shown in Table 3, and the composition of the platinum palladium concentrate is shown in Table 4.

[0026] Table 3 Elemental analysis results before and after platinum palladium solution reduction

[0027]

[0028]

[0029] The element composition analysis result of table 4 platinum palladium concentrate

[0030] the element

[0031] .

Embodiment 3

[0033] Accurately measure 3.00L of platinum-palladium-containing solution and pour it into a 5L reactor, stir and adjust the solution to acidity, heat up to 85°C, then add solid oxalic acid at a rate of 8g / min, and monitor the potential of the reaction solution with a potentiometer. Stop when the solution potential reaches 480mV. After the solution is cooled, the solid and liquid are separated to obtain platinum-palladium-reduced liquid and platinum-palladium concentrate. The volume, main element concentration and precipitation rate of the solution before and after the reaction are shown in Table 5, and the composition of the platinum palladium concentrate is shown in Table 6.

[0034] Table 5 Elemental analysis results before and after platinum palladium solution reduction

[0035]

[0036] The element composition analysis result of table 6 platinum palladium concentrate

[0037] the element

[0038] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com