Secondary mixing method of epoxy resin composition for semiconductor encapsulation

An epoxy resin and secondary mixing technology, which is applied to the preparation field of epoxy resin compositions, can solve the problems of poor fluidity, low mold opening hardness, and many insolubles of epoxy resin compositions, and achieves improved curing characteristics, Improved mold opening hardness and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Components and contents in the epoxy resin composition for preparing semiconductor encapsulation are:

[0031] O-cresol novolac epoxy resin A1 ("N-665" manufactured by DIC Corporation of Japan) 15wt%

[0032] Phenol novolac resin B1 ("TD-2131" manufactured by DIC Corporation of Japan) 7wt%

[0033] 2-Methylimidazole C1 0.15wt%

[0034] 1,8-diazabicyclo(5,4,0)undecene-7C2 0.45wt%

[0035] Silica powder D (d50 is 25μm) 67wt%

[0036] Flame retardant (a mixture of zinc borate, magnesium hydroxide and aluminum hydroxide, wherein the weight ratio of zinc borate: magnesium hydroxide: aluminum hydroxide is 8:2:1; the particle size d50 ranges from 0.1 to 10 μm) E 8wt%

[0037] Carnauba Wax F 0.4wt%

[0038] γ-Glycidyl propyl ether trimethoxysilane G 0.5wt%

[0039] Inorganic ion scavenger H 0.2wt% (Japan TOAGOSEI Co., Ltd system IXE500 (Bi 2 o 3 ·3H 2 O))

[0040] Carbon black I 0.5wt%

[0041] Liquid silicone oil J 0.3wt%

[0042] Silicone rubber powder K 0.5wt% (d...

Embodiment 2~10

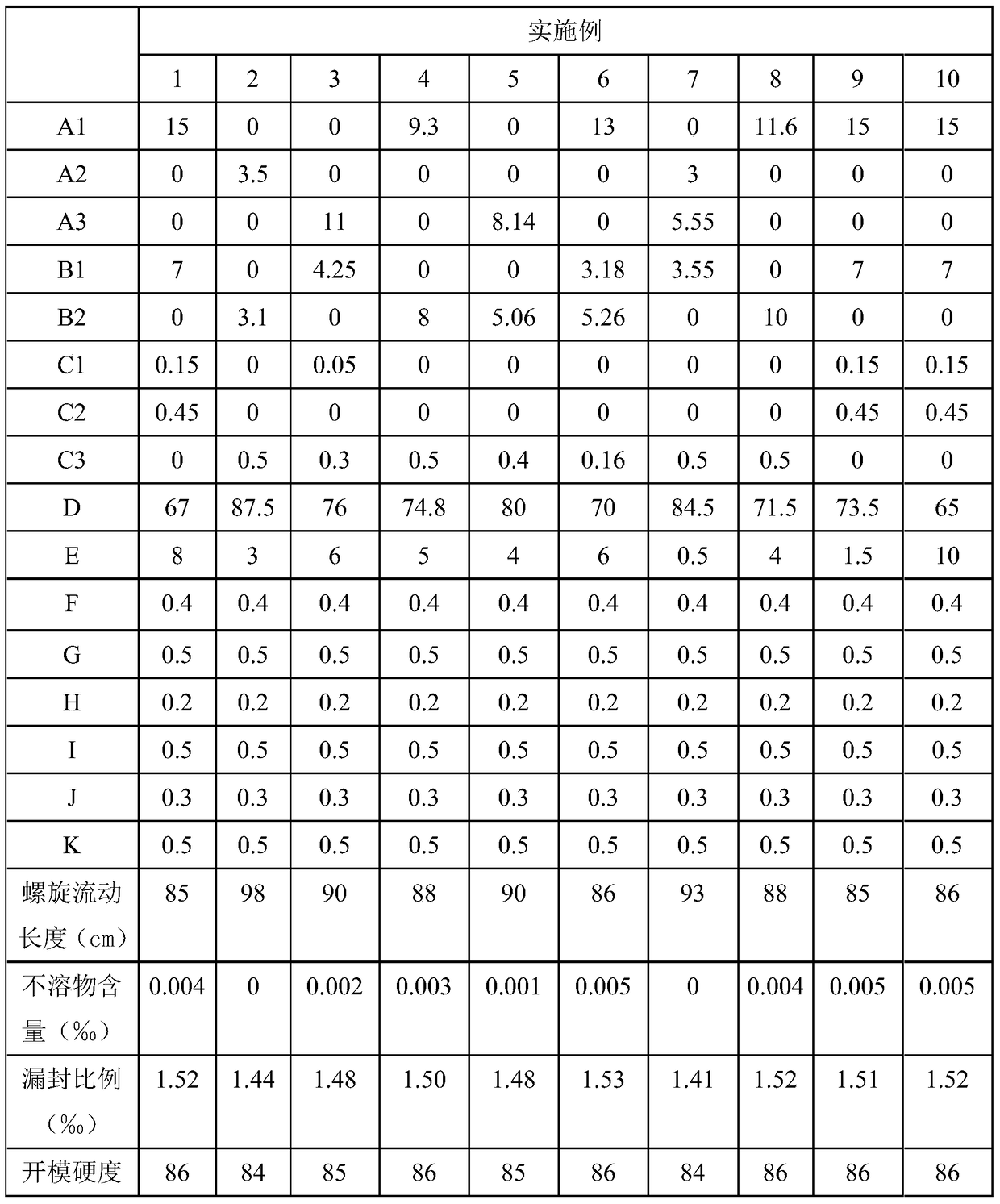

[0050] The composition and content of the epoxy resin composition for semiconductor encapsulation are shown in Table 1, the preparation method is the same as in Example 1, the evaluation method is the same as in Example 1, and the evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com