Preparation method of zirconium-based microporous coordination polymer

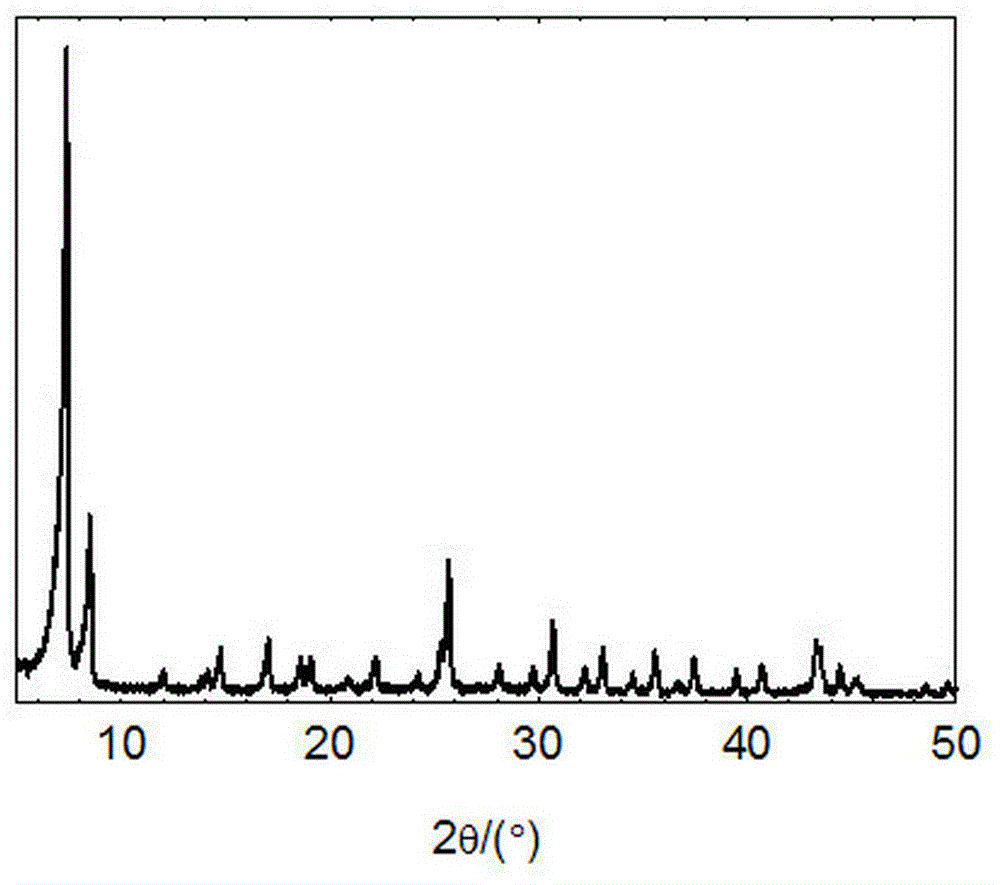

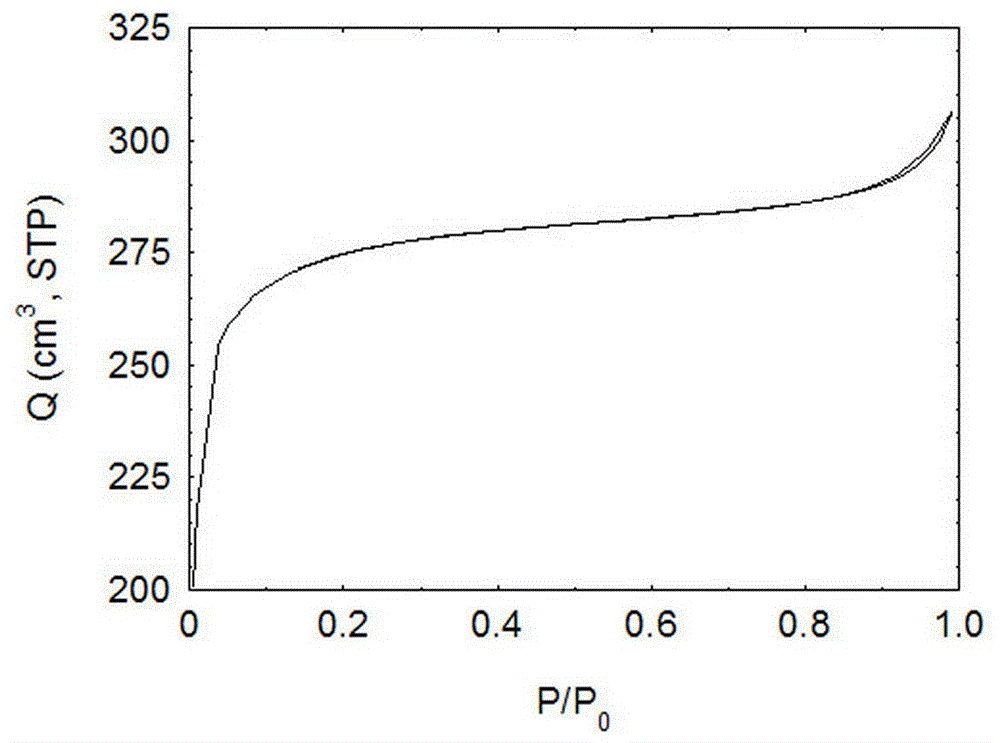

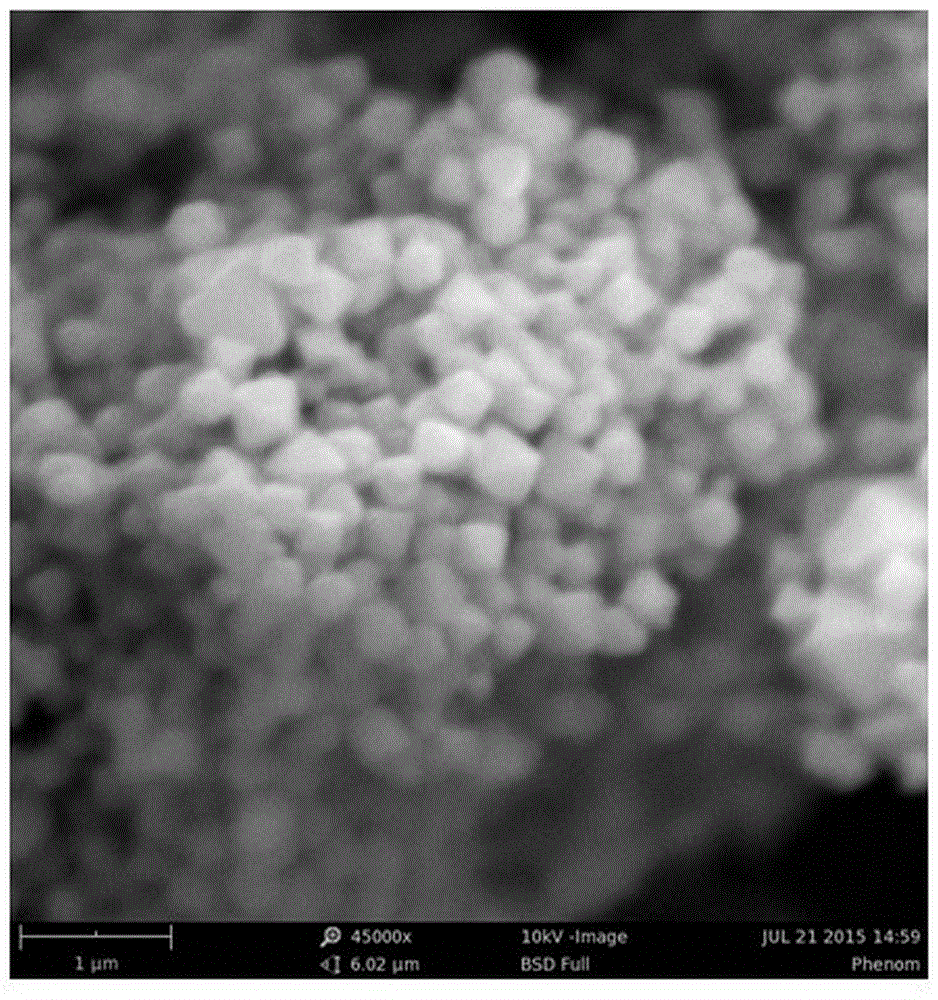

A coordination polymer and microporous technology, applied in chemical instruments and methods, compounds of group 4/14 elements of the periodic table, organic compounds of group 4/14 without C-metal bonds, etc., can solve the problem of small grain size Poor morphology, unfavorable large-scale production, low yield unfavorable large-scale production and other problems, to achieve the effect of complete morphology, improved solvent utilization, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 A preparation method of a zirconium-based microporous coordination polymer, the steps and conditions are as follows: Step 1, under stirring at normal temperature and pressure, as a base material, 51.9g of ZrOCl was mixed in a 50L reaction kettle 2 ·8H 2 O (0.160mol) and 29.2g terephthalic acid (0.176mol) were added to a mixed solvent of 1.2L acetic acid (20.8mol) and 10L of N,N'-dimethylformamide (128mol) to prepare a mixed solution ; ZrOCl 2 ·8H 2 The molar ratio of O: terephthalic acid: acetic acid: N,N'-dimethylformamide is 1:1.1:130:800.

[0030] In step 2, the temperature of the mixed solution in step 1 is raised to 120°C. The total reaction time is 28 hours. The base material is first reacted for 4 hours, and then according to the same ratio as the base material, 51.9g of ZrOCl is added every 4 hours 2 ·8H 2 O (0.160mol) and 29.2g terephthalic acid (0.176mol) were added 5 times in total, and then reacted for 4 hours to stop the reaction. Zr-MOF was s...

Embodiment 2

[0032] Example 2 A preparation method of a zirconium-based microporous coordination polymer, the steps and conditions are as follows: Step 1, under normal temperature and pressure stirring, as a base material, in a 50L reaction kettle, 51.9gZrOCl 2 ·8H 2 O (0.160mol) and 29.2g terephthalic acid (0.176mol) were added to a mixed solvent of 0.6L acetic acid (10.4mol) and 5L of N,N'-dimethylformamide (64mol) to prepare a mixed solution ; ZrOCl 2 ·8H 2 The molar ratio of O: terephthalic acid: acetic acid: N,N'-dimethylformamide is 1:1.1:65:400.

[0033] Step 2, the temperature of the mixed solution in step 1 is raised to 120°C, the total reaction time is 27 hours, the bottom material is reacted for 3 hours first, and then the ZrOCl 2 ·8H 2 : The mol ratio of terephthalic acid is 1:0.45, and feed 103.8gZrOCl is added every 3 hours 2 ·8H 2 O (0.320mol) and 23.9g terephthalic acid (0.144mol) were added 6 times in total, and then reacted for 6 hours to stop the reaction. Zr-MOF w...

Embodiment 3

[0035] Example 3 A preparation method of a zirconium-based microporous coordination polymer, the steps and conditions are as follows: Step 1, under normal temperature and pressure stirring, as a base material, in a 50L reaction kettle, 37.3gZrCl 4 (0.160mol) and 24.3g2-aminoterephthalic acid (0.144mol) were added to a mixed solvent of 0.717L propionic acid (9.6mol) and 10L of N,N'-dimethylformamide (128mol) to obtain Mixed solution; ZrCl 4 : The molar ratio of terephthalic acid: acetic acid: N,N'-dimethylformamide is 1:0.9:60:800.

[0036] In step 2, the temperature of the mixed solution in step 1 is raised to 140°C, and the total reaction time is 30 hours. The base material is first reacted for 6 hours, and then according to the same ratio as the base material, 37.3g of ZrCl is added every 6 hours 4 (0.160mol) and 24.3g 2-aminoterephthalic acid (0.144mol), add a total of 3 times, react for another 6 hours to stop the reaction, separate by centrifugation or filtration, wash t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com