Full-temperature process pressure swing adsorption method for preparing pure methane from natural gas

A pressure swing adsorption, natural gas technology, applied in adsorption purification/separation, chemical instruments and methods, hydrocarbon purification/separation, etc., can solve the problems of difficult desorption, inability to desorb, high energy consumption and investment, and save heat and energy. The effect of regeneration gas, low investment and operating costs, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

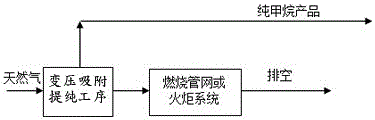

[0034] Such as figure 1 Shown, a kind of whole temperature range pressure swing adsorption method of preparing pure methane from natural gas, the steps of this method are as follows:

[0035] (1) PSA purification process;

[0036] a. In the pressure swing adsorption system, 1000m3 / h raw natural gas enters from the bottom of the adsorption tower and then adsorbed. The adsorption pressure is 0.05~1.5Mpa, the operating temperature is 60~80℃, and multiple adsorption towers are alternately cycled to ensure natural gas Continuous entry; the pressure swing adsorption system is composed of 6 adsorption towers; 1 to 5 adsorption towers are in the adsorption state, and the rest of the adsorption towers are in the regeneration state. one or more kinds;

[0037] b. Unadsorbed CH4 is discharged from the top of the adsorption tower to obtain pure methane products;

[0038] c. The hydrocarbon components such as C2 and above components in the adsorption phase are concentrated to 15~30%, an...

Embodiment 2

[0047] Such as figure 1 Shown, a kind of whole temperature range pressure swing adsorption method of preparing pure methane from natural gas, the steps of this method are as follows:

[0048] (1) PSA purification process;

[0049] a. In the pressure swing adsorption system, 10000m3 / h raw natural gas enters from the bottom of the adsorption tower and then adsorbed. The adsorption pressure is 2.0~3.0Mpa, the operating temperature is 80~110℃, and multiple adsorption towers are alternately cycled to ensure natural gas Continuous entry; the pressure swing adsorption system is composed of 10 adsorption towers; 1 to 9 adsorption towers are in the adsorption state, and the rest of the adsorption towers are in the regeneration state. one or more kinds;

[0050] b. Unadsorbed CH4 is discharged from the top of the adsorption tower to obtain pure methane products;

[0051] c. The hydrocarbon components such as C2 and above components in the adsorption phase are concentrated to 15~30%, ...

Embodiment 3

[0060] Such as figure 2 Shown, a kind of whole temperature range pressure swing adsorption method of preparing pure methane from natural gas, the steps of this method are as follows:

[0061] (1) PSA purification process;

[0062] a. Carry out in pressure swing adsorption system, described pressure swing adsorption system is made up of 10 adsorption towers, wherein 1~9 adsorption towers are in adsorption state, and all the other adsorption towers are in regeneration state, and the packing in adsorption tower is activated carbon, silica gel, One or more of activated alumina and molecular sieves; natural gas is used as raw material, the natural gas enters from the bottom of the adsorption tower and then adsorbed, the adsorption pressure is 3.0~3.5Mpa, the operating temperature is 120~150°C, and multiple adsorption towers are operated alternately and cyclically , to ensure the continuous entry of natural gas;

[0063] b. Unadsorbed CH4 is discharged from the top of the adsorpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com