Modified fiber toughened cement-based material and preparation method thereof

A technology of cement-based materials and modified fibers, which is applied in the field of building materials, can solve the problems of high-toughness cement-based materials attenuation of mechanical properties, brittle cracking, etc., and achieve good slip-pullout effect, attenuation improvement, crack resistance and The effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a modified fiber toughened cement-based material, comprising the following steps: 1). Soak the toughened fiber in an acidic film-forming substance dilution, filter the liquid after 15 minutes, and place it in an environment of 65°C After drying for 20 minutes, rinse and disperse with water and then dry to obtain modified toughened fibers;

[0030] 2). Preparation of toughened cement-based material slurry:

[0031] ① Selection of raw materials: cement, admixture, sand, water, water reducing agent, thickener in parts by mass: 25 parts of cement, 20 parts of admixture, 30 parts of sand, 15 parts of water, 0.1 part of water reducing agent , 0.05 part of thickening agent, choose cement, admixture, sand, water, water reducer and thickening agent, for subsequent use; Step 1) the addition of the modified toughening fiber obtained is 2% of the total volume of the above-mentioned materials, Select modified toughening fiber;

[0032] ②After uniformly mixin...

Embodiment 2

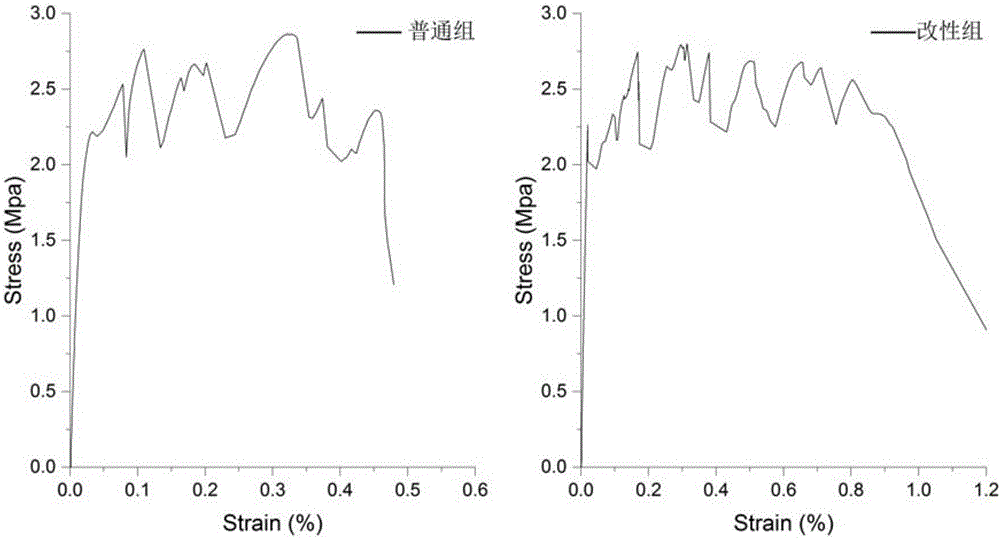

[0041] Embodiment 2 (to domestic fiber modification):

[0042] A method for preparing a modified fiber toughened cement-based material, comprising the following steps: 1). Soak the toughened fiber in an acidic film-forming substance dilution, and after 0.5 min, filter the liquid and place it in an environment of 30°C After drying for 2 hours, rinse and disperse with water and then dry to obtain modified toughened fibers;

[0043] 2). Preparation of toughened cement-based material slurry:

[0044] ① Raw material selection: cement, admixture, sand, water, water reducer, thickener in parts by mass: 20 parts of cement, 10 parts of admixture, 20 parts of sand, 10 parts of water, 0.6 part of water reducer , 0.1 part of thickening agent, select cement, admixture, sand, water and water reducer, standby; Step 1) the addition of the modified toughening fiber obtained is 0.3% of the total volume of the material, select the modified toughening fiber;

[0045] ②After uniformly mixing th...

Embodiment 3

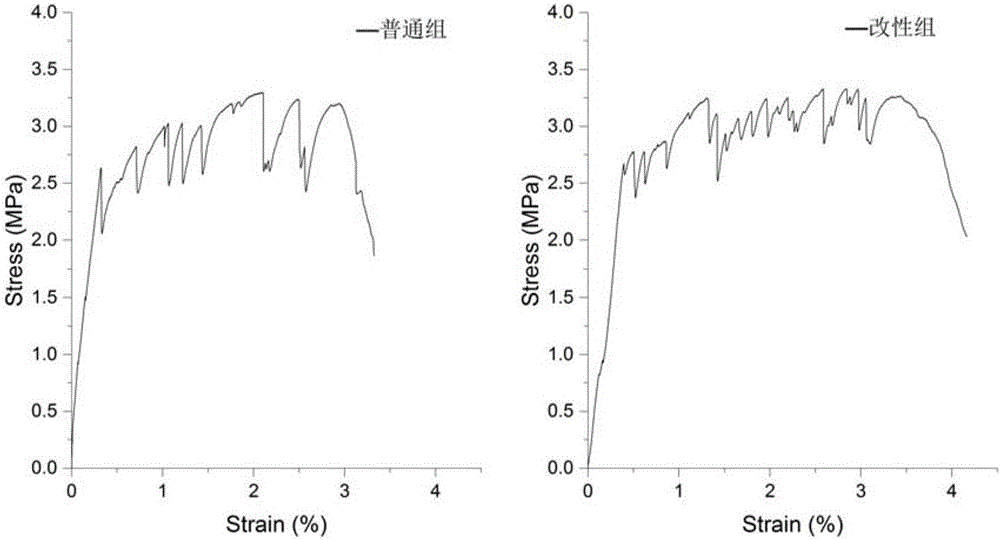

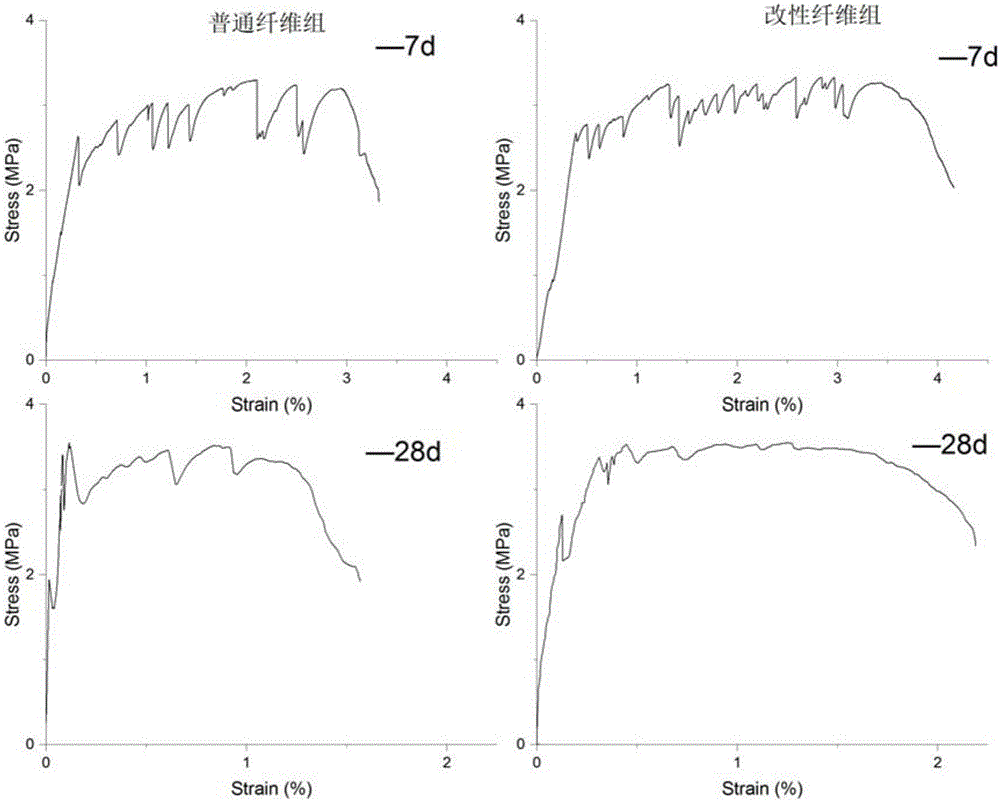

[0053] Example 3: Comparison of the attenuation of mechanical properties of imported fiber modified and unmodified

[0054] Basically the same as Example 1, the difference is:

[0055] The acidic film-forming substance dilution is obtained by mixing boric acid anhydride, styrene-butadiene emulsion and water, and the parts by mass of each raw material are: 1 part of boric acid anhydride, 48 parts of styrene-butadiene emulsion, and 51 parts of water.

[0056] The admixture is metakaolin and silica fume, and the mass ratio of metakaolin to silica fume is 1:1.

[0057] The sand is sand with a particle size less than 0.6 mm.

[0058] The thickener is hydroxypropyl methylcellulose ether.

[0059] The experimental method is the same as that in Example 1, and the results show that the present invention further improves the toughness of existing high-toughness cement-based materials and reduces the decay of mechanical properties of high-toughness cement-based materials over time. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com