Residual pressure type circulating water system discharge water recycling device

A circulating water system and sewage discharge technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, natural water treatment, etc., can solve the problems of high energy consumption and high pressure, and achieve convenient operation and management. The effect of small filter layer thickness and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

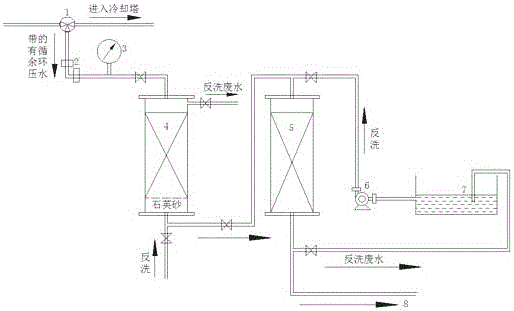

[0034] Example: such as figure 1 As shown, the residual pressure type circulating water system sewage regeneration and reuse device. The sewage is drawn from the three-way valve 1, and the three-way valve is connected to the water inlet of the shallow filter 4 through the pipeline through the pipeline valve 2 and the pressure gauge 3, and the water outlet of the shallow filter 4 is connected to the water outlet of the ion exchanger 5 The water inlets are connected, and the water outlet of the ion exchanger 5 is connected with the sump 8 under the cooling tower. Backwash circuit: the water inlet of the ion exchanger 5 is also connected to the water outlet of the regeneration liquid booster pump 6, the water inlet of the regeneration liquid booster pump 6 is connected to the ion exchange regeneration liquid pool 7, and the water outlet of the ion exchanger 5 It is connected with the water inlet of the ion exchange regeneration liquid pool 7, and the recycling of the ion exchang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com