Coal gas deamination and residual ammonia liquor vacuum distillation integrated production method and system

A technology of gas atomization nozzle and ammonia water, which is applied in combustible gas purification, chemical instruments and methods, combustible gas purification/transformation, etc., can solve the problems of difficult tail gas treatment, large equipment investment, environmental pollution, etc., and achieve reduction of equipment investment, The effect of reducing environmental pollution and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

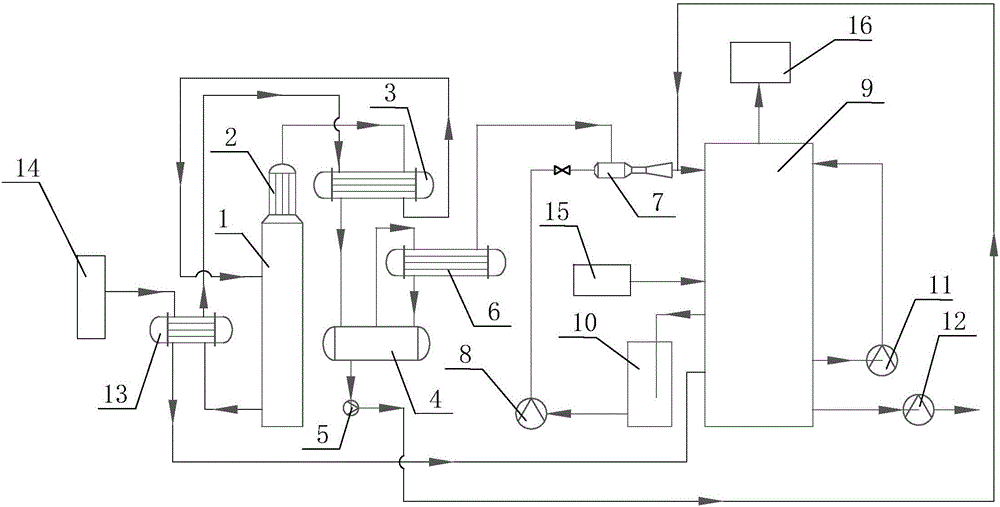

[0036] Such asfigure 1 as shown, figure 1 It is a schematic diagram of the working principle of the integrated production method of coal gas deammonization and residual ammonia water negative pressure ammonia distillation provided by the embodiment of the present invention.

[0037] The invention provides an integrated production method of deammonization of coal gas and negative pressure steaming of residual ammonia water, comprising the following steps:

[0038] 1) The ammonia vapor from the top of the ammonia distillation tower 1 in the remaining ammonia ammonia distillation process is sent to the ammonia splitter 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com