Rotating nozzle device, 3D printer and printing method

A technology of 3D printers and rotary nozzles, applied in the field of 3D printing, can solve problems such as difficult bracket separation of finished products, prolonging printing time, and damage to finished products, and achieve the effects of ensuring integrity, improving flexibility, and improving printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

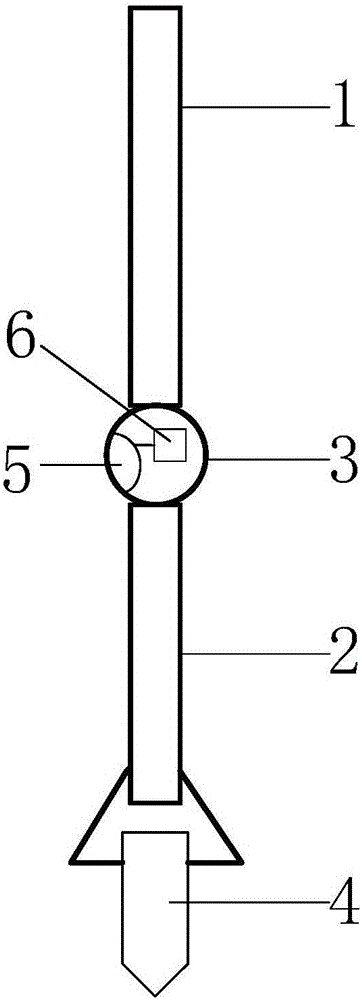

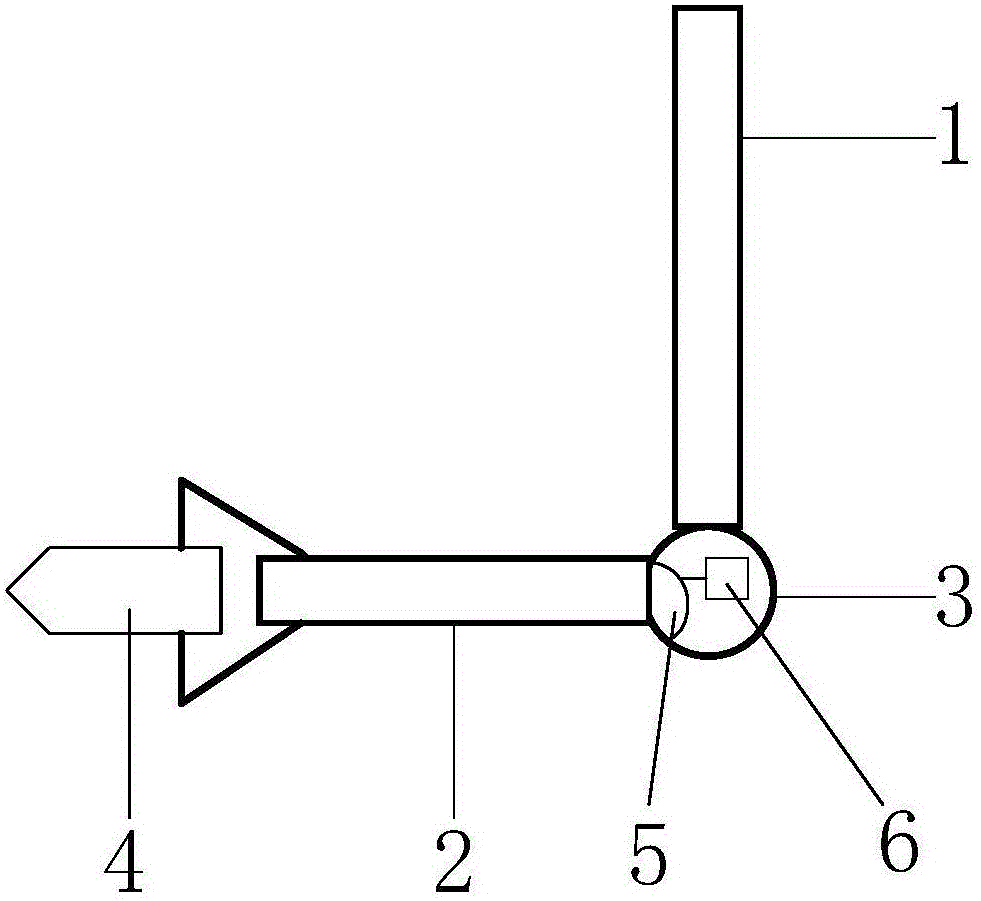

[0039] Example 1: Such as Figure 1-2 As shown, the present invention provides a rotating spray head device, including: a support shaft 1, a rotating shaft 2 and a spray head 4;

[0040] The supporting shaft 1 is installed at the bottom of the body of the 3D printer, one end of the rotating shaft 2 is connected to the supporting shaft 1 through a rotating node 3, and a nozzle 4 is installed on the other end;

[0041] A driver 5 and a sensor 6 are provided in the rotating node 3;

[0042] The sensor 6 is respectively connected to the 3D printer processor and the driver 5. The 3D printer processor is used for slicing processing, determines the rotation angle of the nozzle 4 when printing in the printing area to be supported, and sends the rotation angle to the sensor 6, and the sensor 6 transmits the rotation angle to Drive 5;

[0043] The driver 5 is connected to the rotating node 3, and the driver 5 drives the rotating node 3 to rotate a corresponding angle according to the rotation ...

Embodiment 2

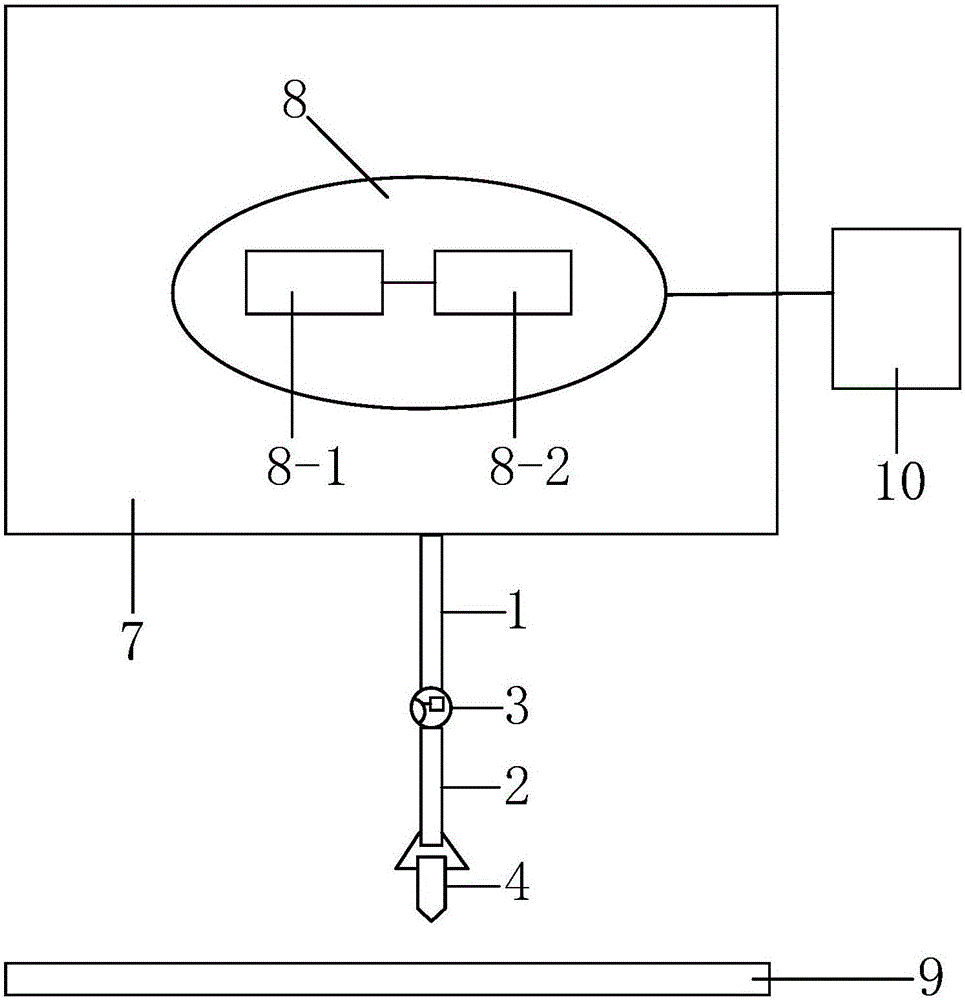

[0044] Example 2: Such as image 3 As shown, the present invention provides a 3D printer, including: the above-mentioned rotating nozzle device, a body 7, a printing base 9 and a scanner 10;

[0045] A processor 8 is provided in the body 7. The processor 8 includes a slicing unit 8-1 and a picture storage unit 8-2, and the picture storage unit 8-2 is connected to the slicing unit 8-1;

[0046] The supporting shaft 1 of the rotating nozzle device is vertically installed at the bottom of the body 7, and the supporting shaft can realize two-dimensional movement on the bottom plane of the body 7, while the supporting shaft 1 remains perpendicular to the bottom of the body 7 during the movement; the sensor 6 of the rotating nozzle device It is connected to the slicing unit 8-1, and is used to receive the information about the rotation angle of the node that needs to be supported in the printing area calculated by the slicing unit 8-1 when slicing; the nozzle 4 of the rotating nozzle devi...

Embodiment 3

[0048] Example 3: Such as Figure 4 As shown, the present invention provides a 3D printer printing method, which can realize the shape of the printed object such as Figure 5 Shown, but the shape of the printed object is not limited to Figure 5 Several object structures shown; including:

[0049] S1. Turn on the printer, and the user judges whether the picture to be printed is in the picture storage unit. If it is in the picture storage unit, the picture to be printed is transferred to the slicing unit for size scaling and slicing; if the picture to be printed is not in the picture storage unit, The image storage unit scans the object to be printed through the scanner, and performs corresponding scaling processing on the scanned image and stores it in the image storage unit or imports the object image to be printed into the image storage unit.

[0050] S2. Analyze the posture of the printed model before slicing, and place it according to the optimal posture of the printed model (th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com