A production line sand return system

A production line and sand blasting technology, applied in the field of sand return system, can solve the problems of increased complexity of sand blasting machines, increased procurement costs, etc., and achieve the effect of a reliable and complete processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

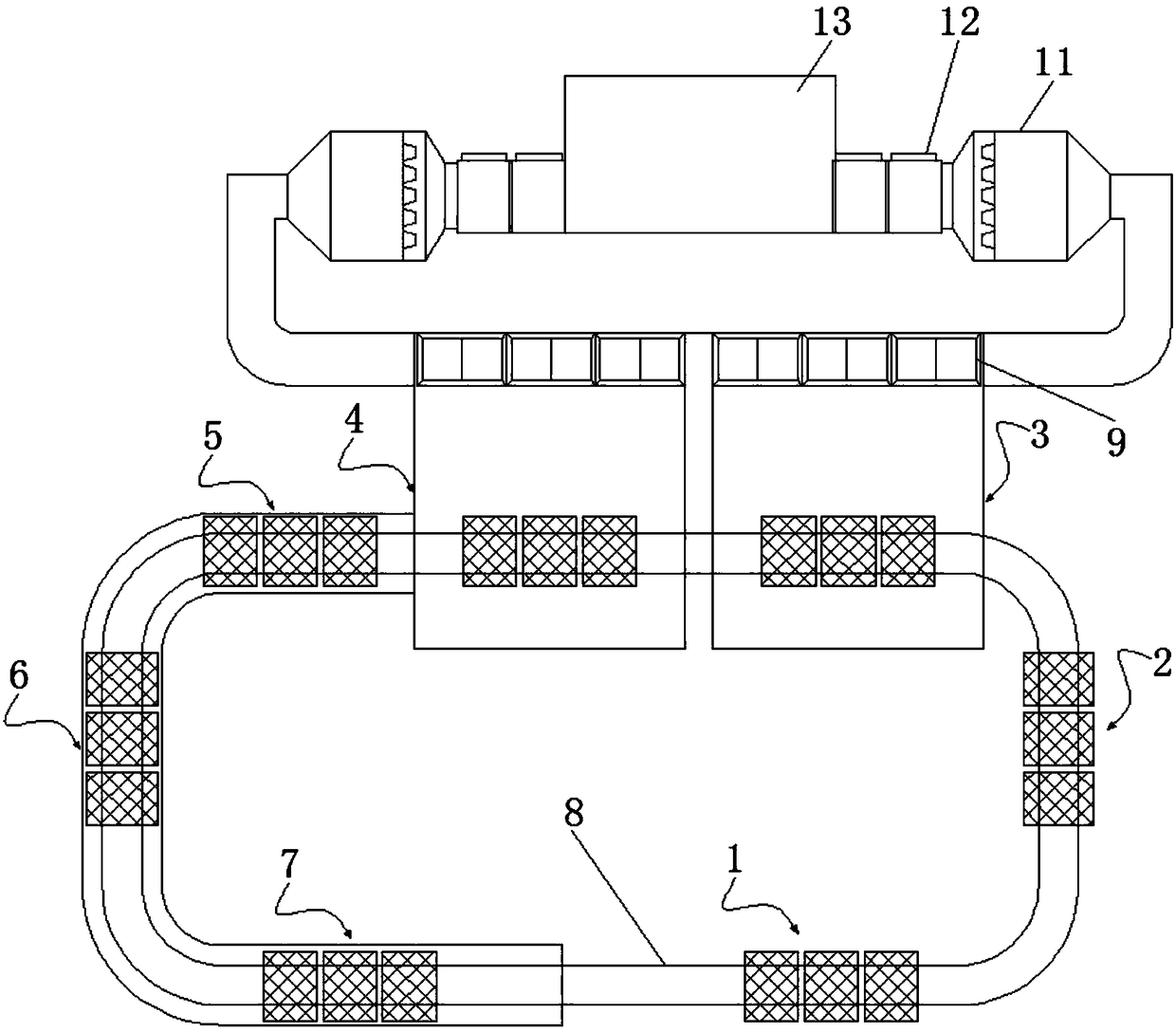

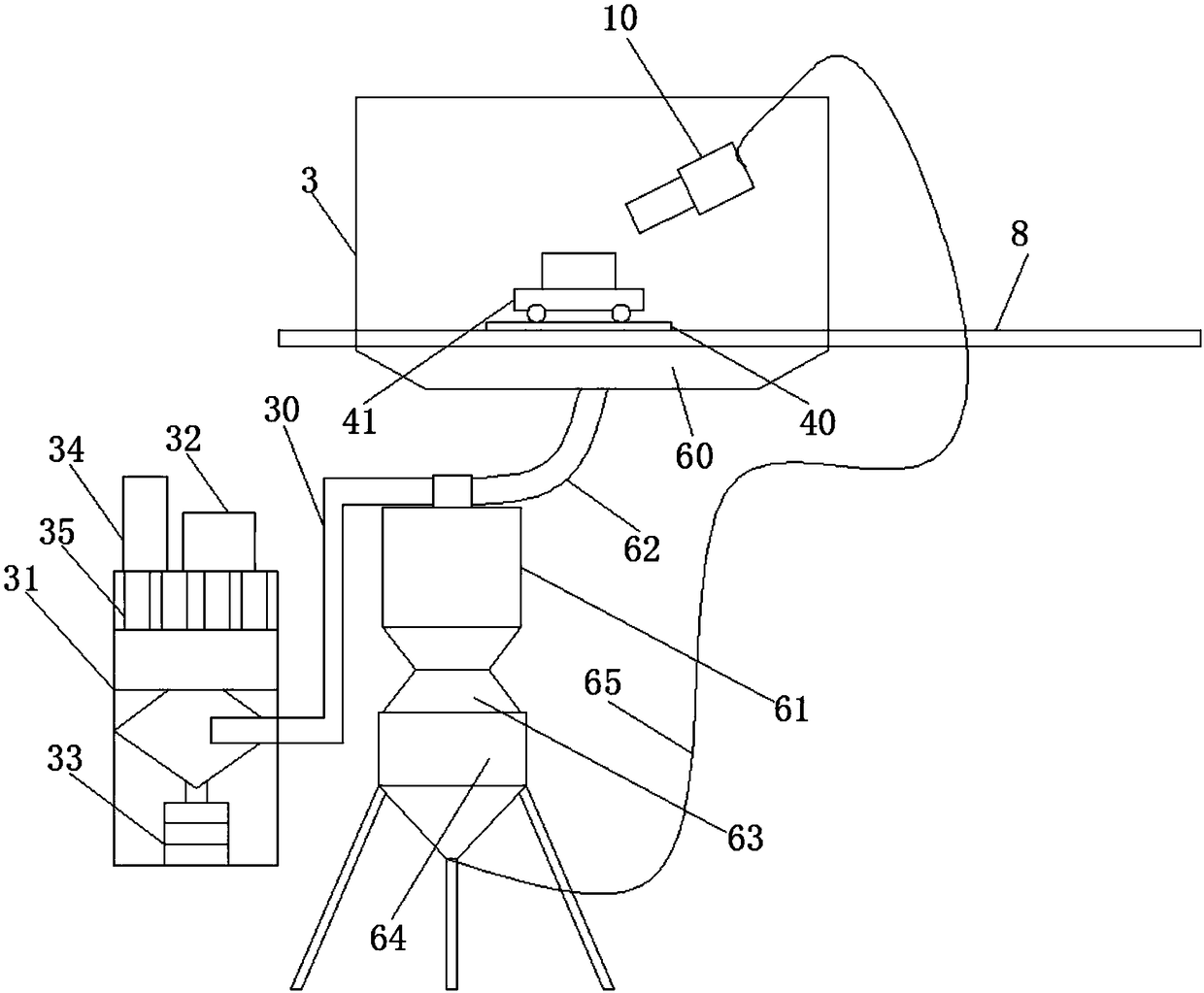

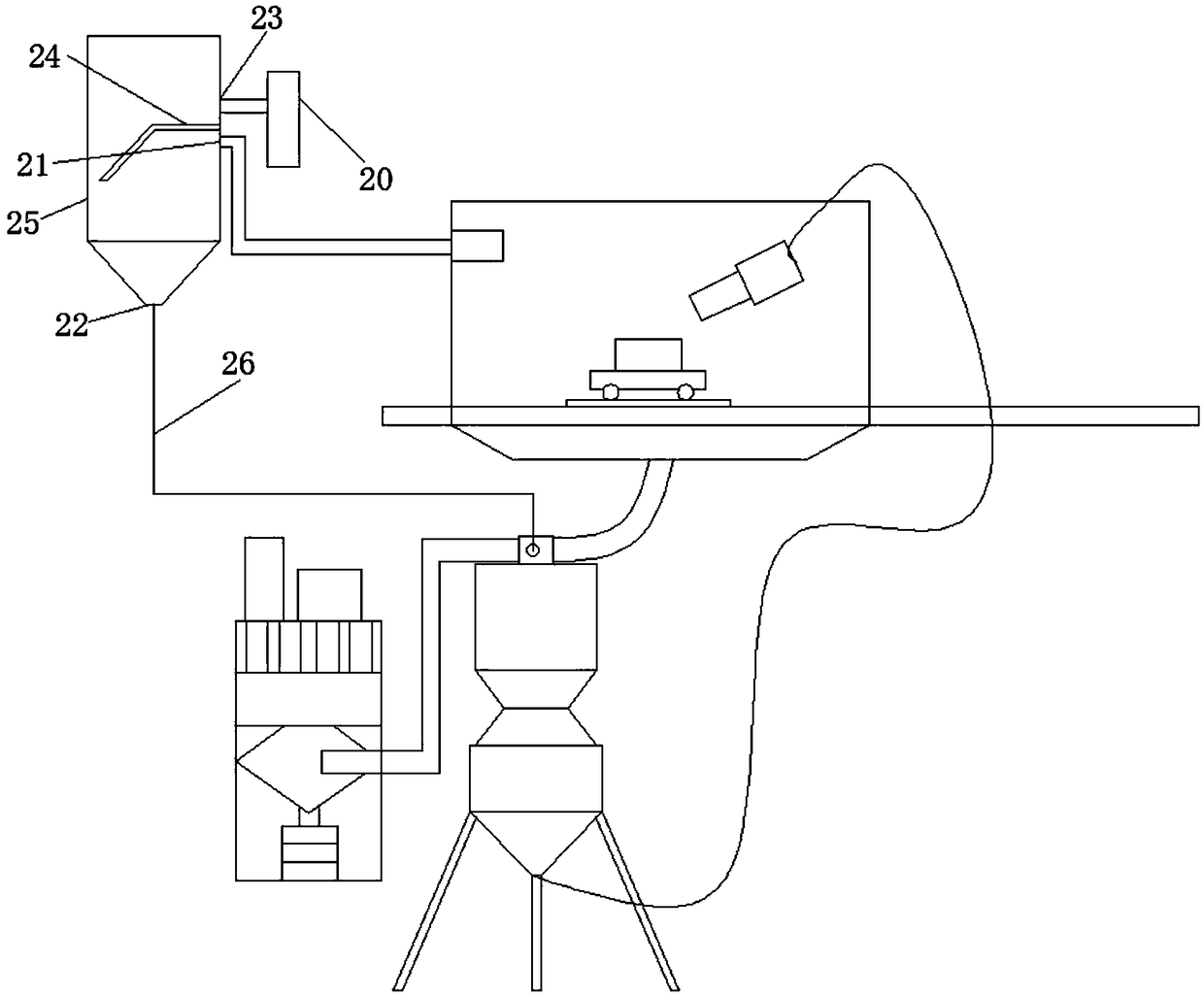

[0031] like Figure 1~3 As shown, it shows the specific implementation of the present invention. As shown in the figure, the present invention discloses a sand return system for a production line, which is used to recycle the waste sand generated in the workpiece sand blasting system; the workpiece sand blasting system includes A processing flow line 8 for transferring workpieces. The processing flow line is provided with a loading area 2, a sandblasting room 3 for sandblasting devices, a paint spraying room 4, a preheating area 5, a baking area 6, The cooling zone 7 and the next piece zone 1; the entire processing flow line is in a ring structure;

[0032] As shown in the figure, a sandblasting device 10 is set in the sandblasting room; the workpiece is set on a mobile trolley 41, and the moving car is set on a fixed seat 40, and the fixed seat is driven by the processing flow line ;

[0033] As shown in the figure, a sand return tank 60 for collecting waste sand is set und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com