Automatic gas valve assembly line

A gas valve and assembly line technology, which is applied in the direction of assembly machines, measuring devices, instruments, etc., can solve the problems of increasing the difficulty of production management, affecting product reliability and cost rate, and low processing efficiency, so as to reduce labor costs and human factors. The impact of products, improving production assembly efficiency and detection accuracy, and realizing the effect of automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

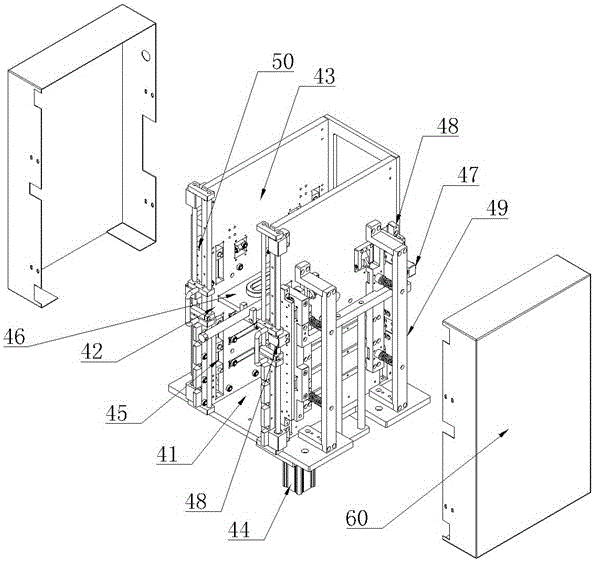

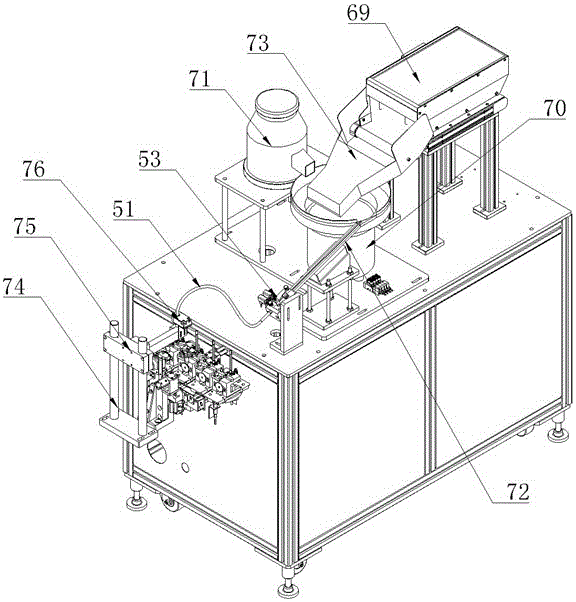

[0026] Such as Figure 1 to Figure 12 As shown, the present invention includes a frame body 1, an assembly part and a detection part arranged on the frame body 1, a connecting conveyor belt 2 is arranged between the assembly part and the detection part, and a connecting conveyor belt 2 is arranged in the assembly part. There is a closed-loop conveyor belt, and the assembly part includes an inner nozzle assembly station 3, a valve core loading station 4, a spring feeding station 5, a valve cover installation station 6, and a screwing station 7, and the inner nozzle assembly station Between the station 3 and the valve core feeding station 4, between the valve core feeding station 4 and the spring feeding station 5, a valve body blowing station 35 and a grease filling station are respectively arranged. Station 36 and uniform grease station 8 are also provided with a spring detection station 9 and a screw detection station 31 beside the screw station 7, and an LP nozzle installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com