Rotary welding device

A welding device and rotary technology, applied in welding equipment, resistance welding equipment, transportation and packaging, etc., can solve the problems of lower welding yield and welding efficiency, sticking needle phenomenon, unsightly surface, etc., and improve the quality of welding process , meet high technical requirements, overcome the effect of sticking needle phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

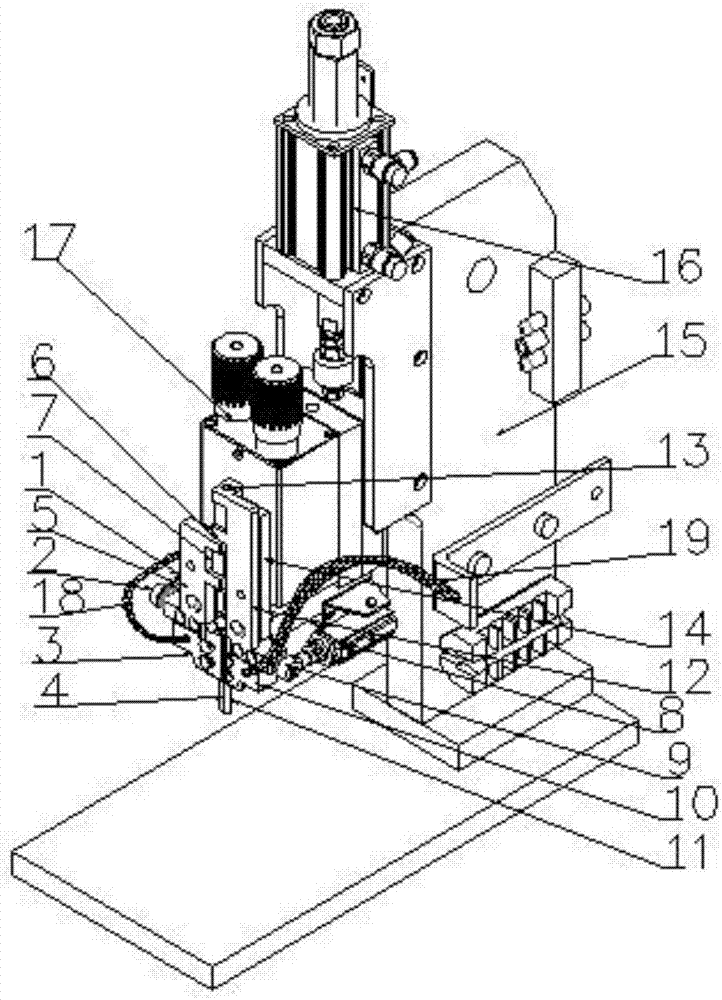

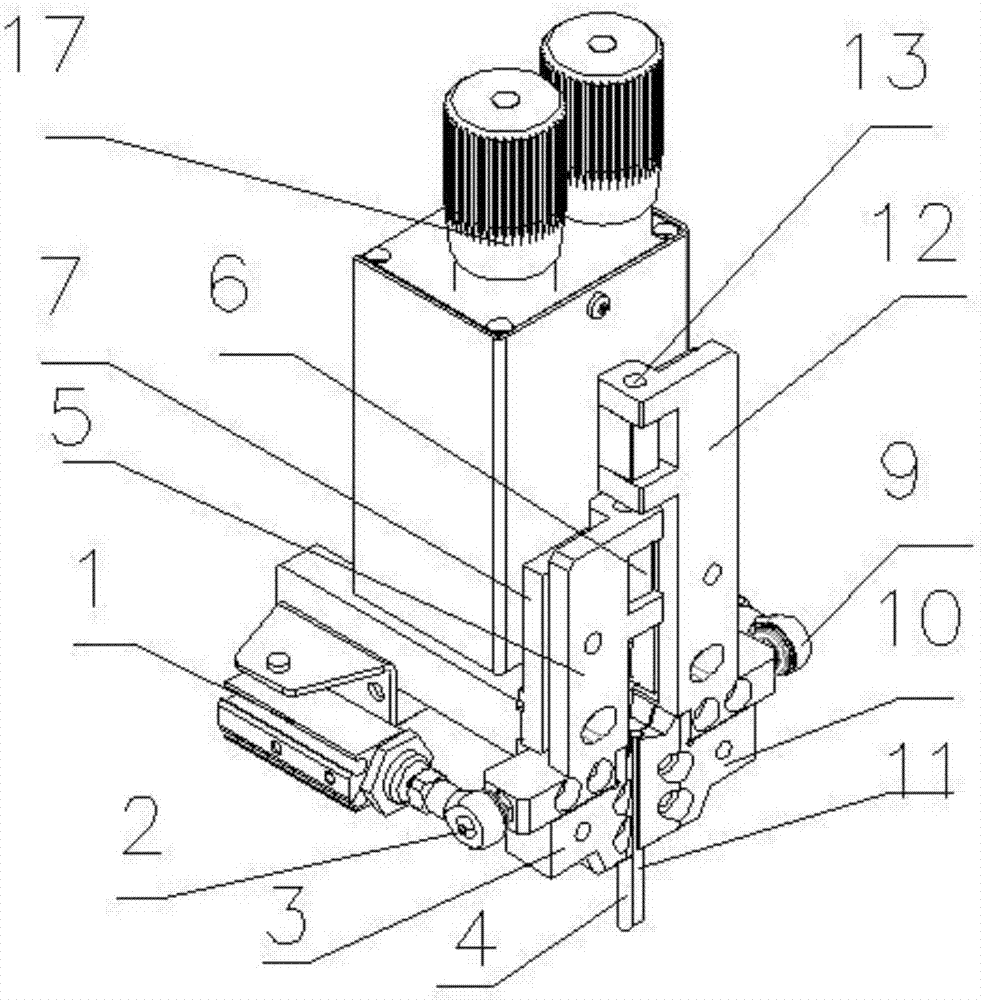

[0020] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-2 As shown, a rotary welding device includes a bracket main body 15, a welding head 17 and a stroke cylinder 16, the left and right sides of the welding head 17 are respectively equipped with a small cylinder A1 and a small cylinder B8, and the center of the front side of the welding head 17 A fixed hinge A7 and a fixed hinge B14 are respectively installed on both sides of the line; the fixed hinge A7 is connected to the rotary hinge A5 through the rotating shaft A6, and the rotary hinge A5 is connected to the small cylinder A1 through the movable joint A2; The bottom of the above-mentioned rotary hinge A5 is connected with the electrode holder A3; the above-mentioned electrode holder A3 clamps the electrode welding pin A4; the above-mentioned fixed hinge B14 is connected to the rotary hinge B12 through the rotating shaft B13, B12 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com