An automatic wire feeding device on a mechanical welding arm

A technology of mechanical welding and wire feeding device, used in tin feeding device, welding equipment, metal processing equipment and other directions, can solve the problems of physical injury of welding personnel, production efficiency and production volume can not meet production needs, etc., to improve welding The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

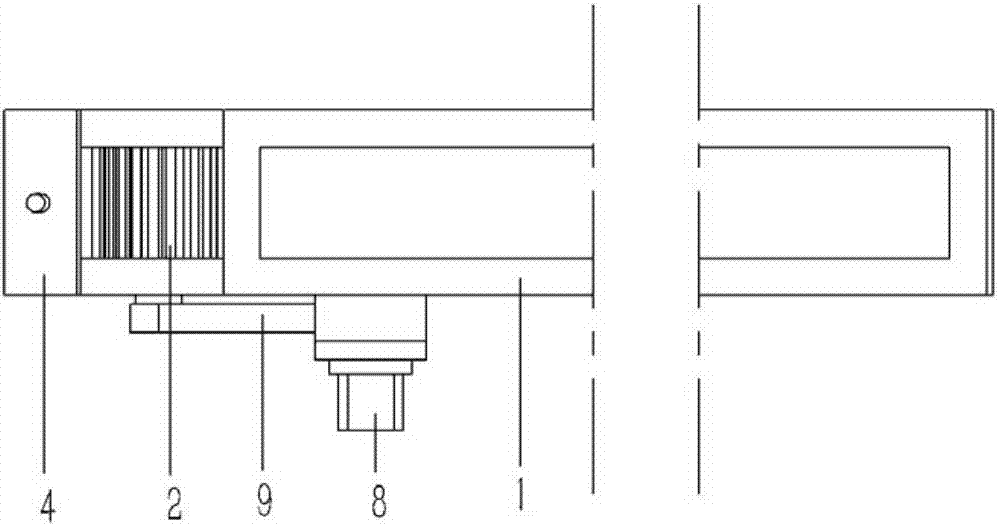

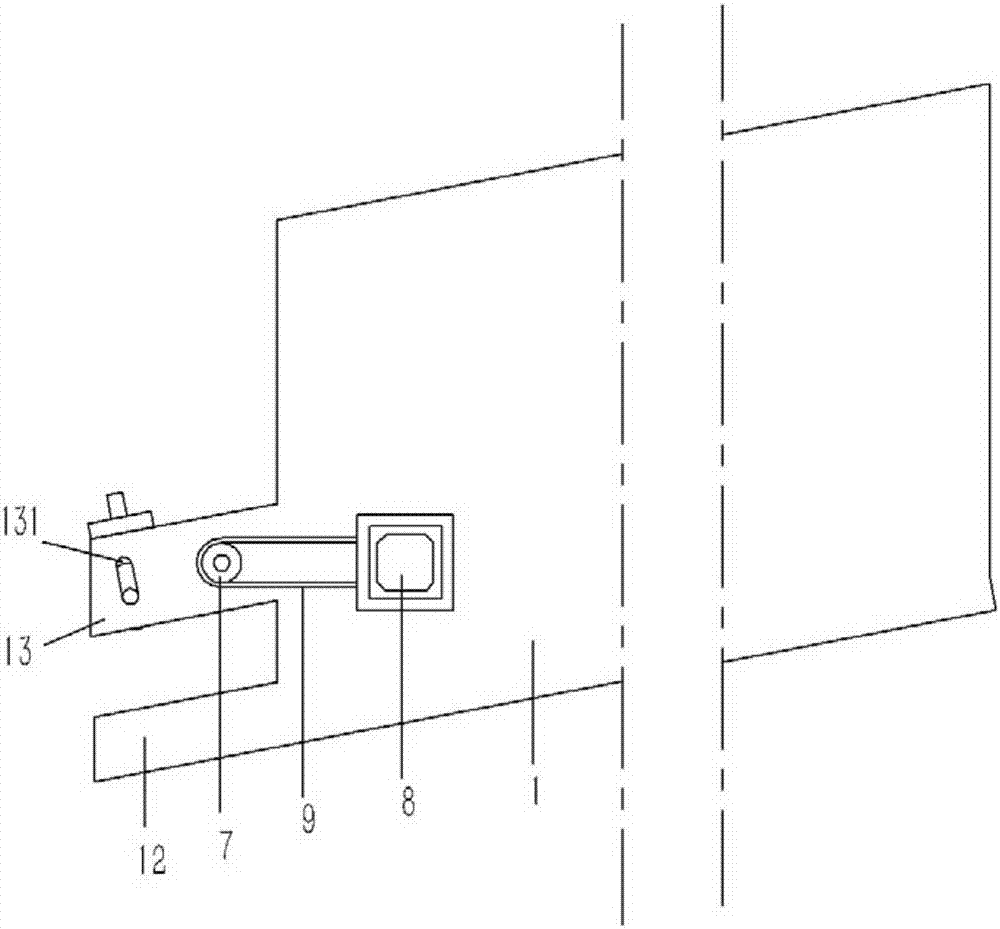

[0014] Example: see Figures 1 to 4 As shown, an automatic wire feeding device on a mechanical welding arm, including a flat wire feeding box 1, an inclined inner bottom surface is formed inside the wire feeding box 1, and the inner side of the lower end side of the inner bottom surface of the wire feeding box 1 is A wire feeding port 11 is formed on the wall, and an inclined wire feeding channel 12 is formed on the outer side of the wire feeding material box 1 outside the wire feeding port 11. A driving wheel 2 and a positioning wheel 3 are arranged above the wire feeding channel 12 to drive There are several triangular sawtooths 21 formed on the outer wall of the wheel 2, and the two ends of the mandrel of the driving wheel 2 are hinged on the lugs 13, and the lugs 13 are formed on the outer wall of the wire feeding box 1, and the lugs 13 are Formed with a waist-shaped hole 131, the two ends of the mandrel of the positioning wheel 3 are plugged in the waist-shaped hole 131 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com