A hydraulic switching device applied to the processing of disk parts

A technology of hydraulic switching device and disc-type parts, applied in the direction of chuck, etc., can solve the problems of inability to guarantee processing safety and efficiency, out-of-tolerance tolerance of parts, and workpiece clamping deformation, so as to eliminate deformation and realize pressure relief. The effect of processing and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In the embodiments, parts of the same configuration are given the same reference numerals and descriptions are omitted.

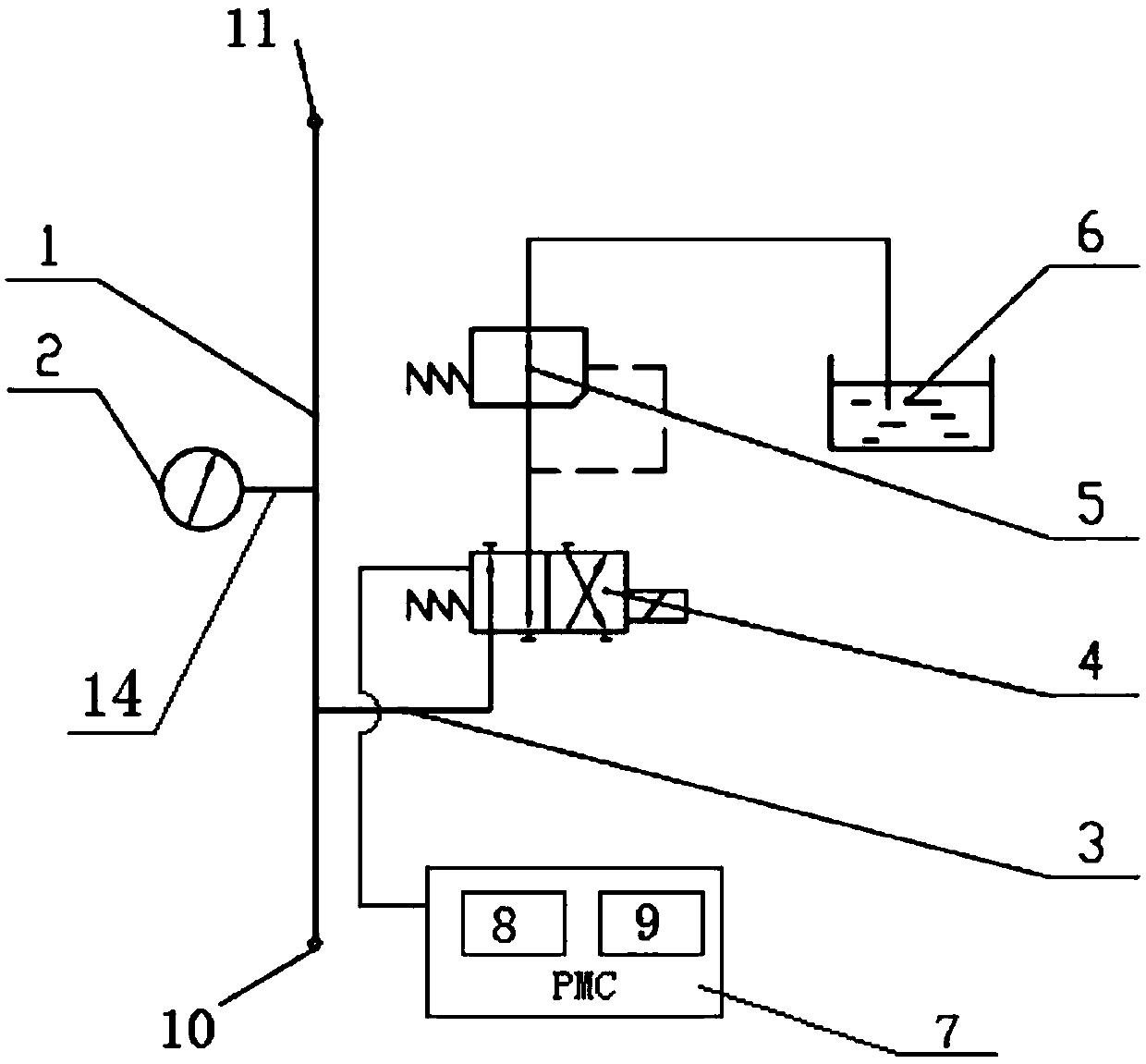

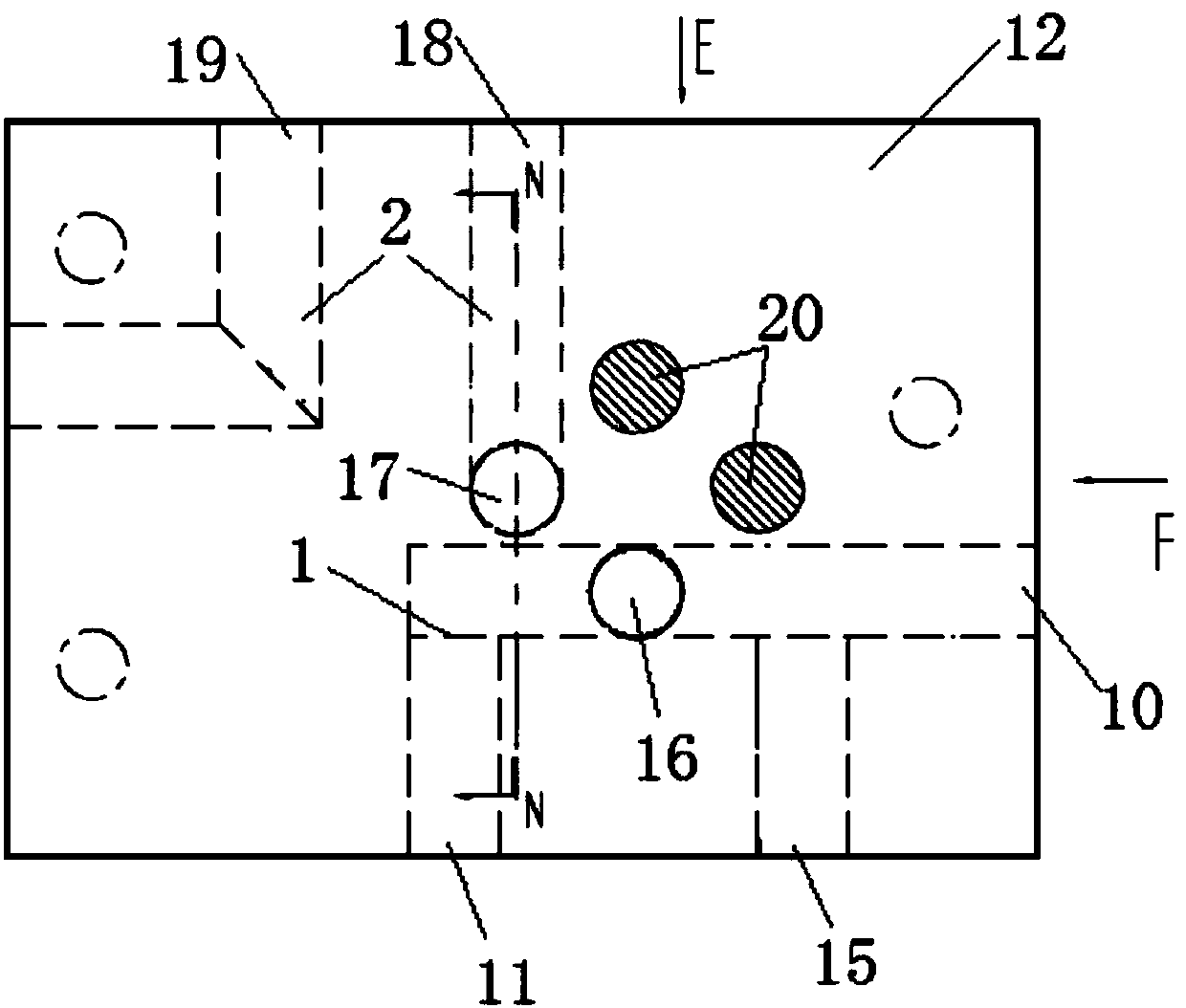

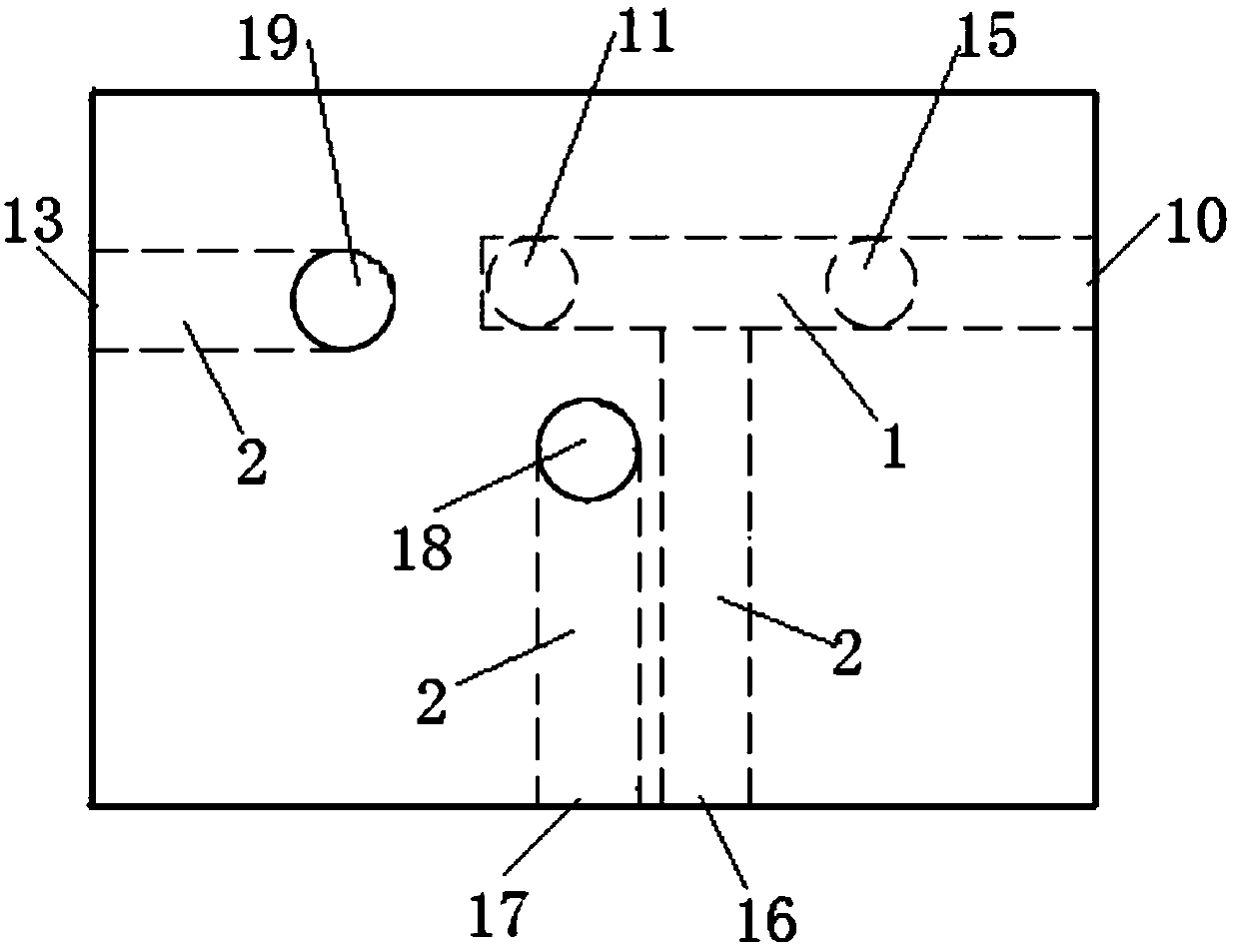

[0032] refer to figure 1 , is a structural schematic diagram of the hydraulic switching device applied to the processing of disk parts according to the present invention; and Figure 2a , is a structural schematic diagram of the distributor 12 of the hydraulic switching device applied to the processing of disk parts according to the present invention.

[0033] As shown in the figure, the hydraulic switching device is installed in an external machine tool for parts processing, including a distributor 12, a solenoid valve 4, and an overflow valve 5.

[0034] The distributor 12 is provided with a first oil passage 1 and a second oil passage 2 in communication. The outlets at both ends of the first oil passage 1 are the oil inlet 10 and the oil outlet 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com