Multi-pole distribution combination type current inversion efficient electric precipitator

An electrostatic precipitator and combined technology, applied in the direction of external electrostatic separator, electrode structure, electrostatic separation, etc., can solve the problems of secondary dust, high-resistance particles cannot be absorbed by residence time, etc., to prevent back corona, improve effective Contact frequency, the effect of efficient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

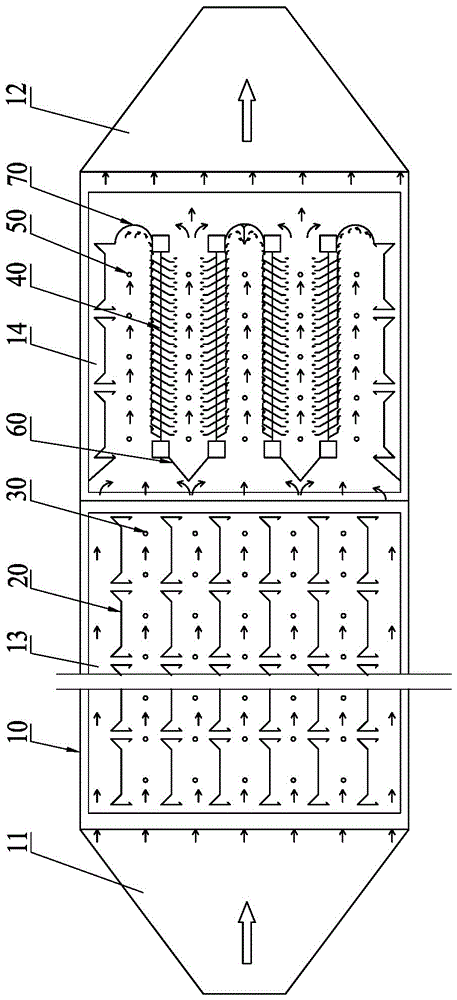

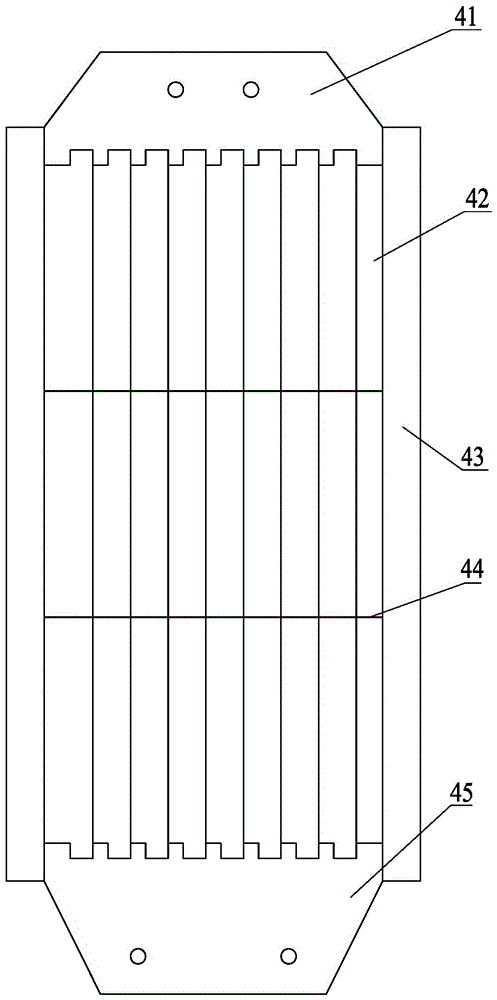

[0034] Please refer to figure 1 As shown, it shows the specific structure of the first preferred embodiment of the present invention, including housing 10, a plurality of common electric field anode plates 20, a plurality of common electric field cathodes 30, a plurality of grid shutter anode plates 40, A plurality of final electric field cathodes 50 , a plurality of front baffles 60 and a plurality of rear baffles 70 .

[0035] The front end of the housing 10 has a smoke inlet 11, the rear end of the housing 10 has a smoke outlet 12, and the housing 10 has a front accommodating cavity 13 and a rear accommodating cavity 14 communicating with each other, the front accommodating cavity 13 It communicates with the smoke inlet 11 , and the rear accommodating cavity 14 communicates with the smoke outlet 12 .

[0036] The plurality of common electric field anode plates 20 and the plurality of common electric field cathode plates 30 are all arranged in the front accommodating cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com