A kind of iron ore circular classification beneficiation method and dry separation machine applied to the method

A beneficiation method and technology of dry separator, applied in chemical instruments and methods, solid separation, magnetic separation, etc., can solve problems such as increased cyclic load, and achieve low cyclic load, high system capacity utilization, and low tailings grade. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

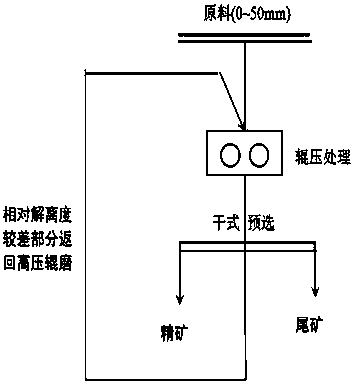

[0032] see figure 1 , a kind of iron ore circular classification ore dressing method, comprises the following steps:

[0033] Step 1: Input the raw ore with a particle size of 0 to 50mm into a high-pressure roller mill for rolling. After the rolling index reaches the standard, the rolled product is transported to a dry magnetic separator for dry separation. Mines and tailings are three products;

[0034] Step 2: Return the above medium ore to the feed bin of the high pressure roller mill, form a mixture with the new raw ore and continue rolling, repeat the above step 1, and form a closed circuit;

[0035] Step 3: The sorted concentrate and tailings obtained in Step 1 and Step 2 are transported to the concentrate stockpile and tailings stockpile respectively by the receiving belt to complete the ore dress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com