Method for filtering and recovering solid particles in mother solution at PTA oxidation stage and filter using method

A solid particle, oxidation stage technology, applied in fixed filter element filters, chemical instruments and methods, filtration and separation, etc., can solve the problems of many process links, high operating costs, cumbersome and other problems, so as to solve the problem of poor filtration effect and save money. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

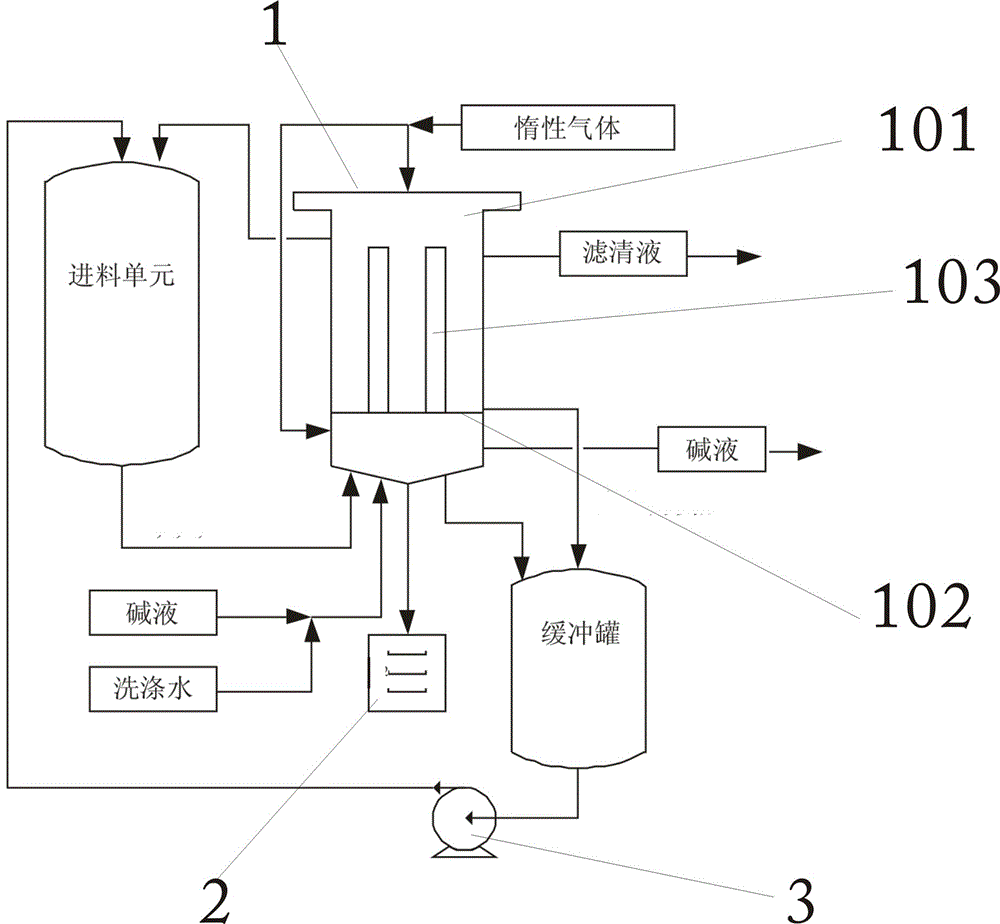

[0047] like figure 1 As shown, the present invention provides a system for filtering and recovering solid particles in the mother liquor of the PTA oxidation stage, including a filter 1, a feed unit, an alkali washing solution supply unit, a gas supply unit, a buffer tank and a drying unit. The alkaline cleaning solution supply unit includes an alkaline solution unit and a cleaning solution unit that share a set of pipelines connected to the filter, so as to facilitate alkaline cleaning of the equipment after a certain working period. The filter includes an inner cavity 101, a tube plate 102 and a filter element 103; the tube plate is arranged in the inner cavity and divides the inner cavity into two parts; the filter element is fixedly installed on the tube plate; There are also r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com