Potato-sour milk tablets

A technology of potato and yogurt slices, applied in the directions of milk preparations, dairy products, applications, etc., can solve the problems of difficulty in promoting gastrointestinal motility, the cost of a lot of manpower and financial resources, and the decline in functionality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

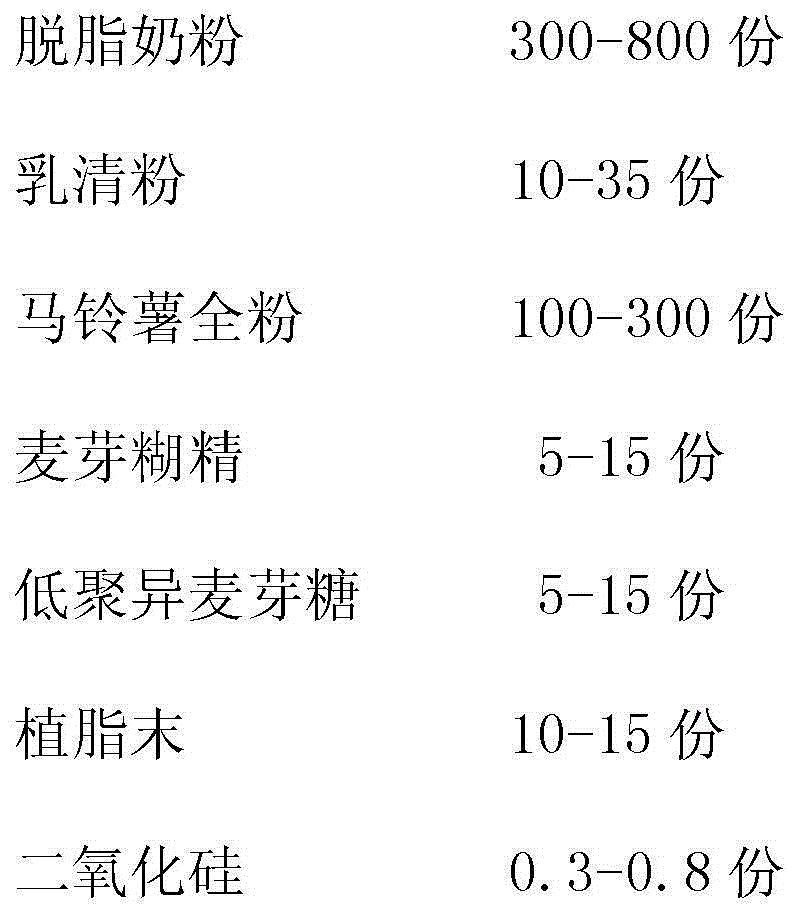

Method used

Image

Examples

Embodiment 1

[0012] This embodiment provides a method for preparing potato yogurt slices. In terms of parts by weight of the potato yogurt slices, the raw material of the potato yogurt slices is composed of: 410 parts of skim milk powder; 20 parts of whey powder; 210 parts of whole potato powder; 10 parts of maltodextrin; 13 parts of fat powder; 0.15 parts of sugar; 0.20 parts of fruit powder, 0.05 parts of essence, and 0.5 parts of silicon dioxide.

[0013] The preparation method of this potato yoghurt sheet comprises the following steps:

[0014] 1. Fermentation: Dissolve skimmed milk powder in warm water at 22°C, filter and sterilize it, put it into a fermenter, mix with an appropriate amount of bacteria, and stir for 12 minutes, stop fermentation when the pH value is 4.2, and then stir for 5 minutes get fermented milk;

[0015] 2. Spray drying: heat the fermented milk to 65°C after homogenization, and keep it for 18 minutes for sterilization, then adjust the temperature of the feed l...

Embodiment 2

[0019] This embodiment provides a method for preparing potato yogurt slices. In terms of parts by weight of potato yogurt slices, the raw material composition of the potato yogurt slices is: 680 parts of skimmed milk powder; 32 parts of whey powder; 300 parts of whole potato powder; 5 parts of maltodextrin; 5 parts of isomaltooligosaccharide; 10 parts fat powder; 5 parts sugar; 2 parts fruit powder, 1 part essence, 0.5 parts silicon dioxide.

[0020] The preparation method of this potato yoghurt sheet comprises the following steps:

[0021] 5. Fermentation: Dissolve skimmed milk powder in warm water at 25°C, filter and sterilize it, put it into a fermenter, mix with an appropriate amount of bacteria, and stir for 10 minutes, stop fermentation when the pH value is 4.5, and then stir for 10 minutes get fermented milk;

[0022] 6. Spray drying: heat the fermented milk to 70°C after homogenization, and keep it for 20 minutes for sterilization, then adjust the temperature of the ...

Embodiment 3

[0026] This embodiment provides a method for preparing potato yogurt slices. In terms of parts by weight of potato yogurt slices, the raw material composition of the potato yogurt slices is: 750 parts of skim milk powder; 35 parts of whey powder; 300 parts of whole potato powder; 12 parts of maltodextrin; 15 parts of isomaltooligosaccharide; 10 parts of fat powder; 8 parts of sugar; 3 parts of fruit powder, 0.08 parts of essence, and 0.7 parts of silicon dioxide.

[0027] The preparation method of this potato yoghurt sheet comprises the following steps:

[0028] 9. Fermentation: Dissolve skimmed milk powder in warm water at 30°C, filter and sterilize it, put it into a fermenter, mix with an appropriate amount of bacteria, and stir for 15 minutes, stop fermentation when the pH value is 5.0, and then stir for 5 minutes get fermented milk;

[0029] 10. Spray drying: heat the fermented milk to 65°C after homogenization, and keep it for 20 minutes for sterilization, then adjust t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com