Production method of nonpathogenic fusarium oxysporum-containing plant vaccine preparation

A technology of Fusarium oxysporum and plant vaccines, applied in botany equipment and methods, plant growth regulators, chemicals for biological control, etc., can solve the problems of tomato wilt difficult to control and reduce the use of chemical pesticides, etc. Achieve the effects of improving resource reuse efficiency, simple and easy preparation process, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

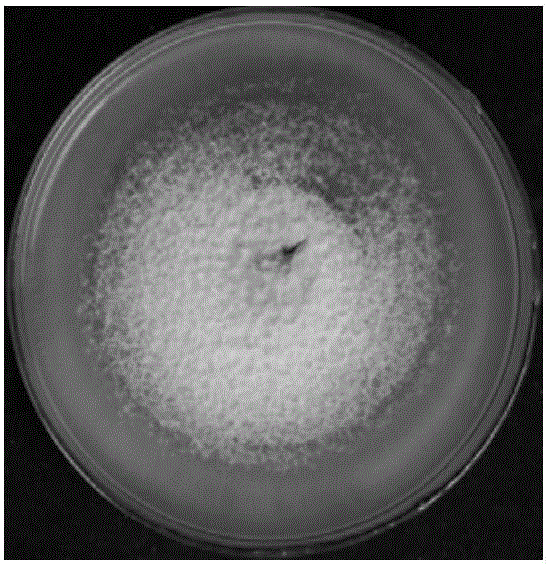

Image

Examples

preparation example Construction

[0032] Step (1) Preparation of liquid strains for production: use non-pathogenic Fusarium oxysporum FJAT-9290 (Fusariumoxysporum) as strains, and use potato dextrose agar PDA medium and Saccharomyces chabzie nutrient solution as liquid strains for cultivation base, to prepare liquid strains for production;

[0033] Step (2) Preparation of non-pathogenic Fusarium oxysporum plant vaccine preparation: the solid medium for plant vaccine production is prepared with pig manure waste as the main component, mixed with bran and wheat grains, and then packed in polypropylene In a plastic bag, after sterilization, inoculate the liquid strain prepared in step (1), culture and ferment at a constant temperature of 28-30°C for 18-20 days to prepare a solid fermentation product of plant vaccine, and mix it well after the fermentation to obtain non-toxic Pathogenic Fusarium oxysporum plant vaccines;

[0034] The Fusarium oxysporum FJAT-9290 (Fusariumoxysporum) was preserved on March 29, 2012 ...

Embodiment 1

[0065] (1) Preparation of liquid strains for production:

[0066] A. Activation of strains: Potato dextrose agar (PDA) medium was prepared, sterilized at 121°C for 20 minutes, cooled to 45-50°C and poured into a sterilized plate for later use. Take the non-pathogenic Fusarium oxysporum FJAT-9290 (Fusarium oxysporum) strain stored at -70°C and culture it by streaking on a PDA plate, and culture at a constant temperature of 28-30°C for 5-7 days;

[0067] The PDA medium: weigh 200g after peeling the potatoes, cut into small pieces of 1cm×1cm, boil for 30min, add 20g of sucrose and 17-20g of agar after filtering through eight layers of gauze, the pH is natural, fully dissolve and set the volume to 1000ml , according to the bottled volume of 200ml / 250ml, sub-package in Erlenmeyer flasks for sterilization;

[0068] B. Inoculate the mycelium in the picking step A in the potato glucose liquid medium, cultivate for 4 to 5 days at 28 to 30° C., and 170 to 200 rpm on a shaker;

[0069]...

Embodiment 2

[0079] (1) with embodiment 1 step (1)

[0080] (2) Utilize the same pig manure waste of embodiment 1 as main culture substrate to produce plant vaccine preparation:

[0081] C. mix by the pig manure waste of 900g and the bran of 100g as basal medium;

[0082] D. Add 400g of wheat grains, 30g of sucrose and 2g of sodium nitrate for every 1000g of basal medium, stir well, add appropriate amount of water, adjust the water volume ratio to 50%, transfer it to a polypropylene plastic bag, and sterilize ;

[0083] The wheat grains need to be soaked for 12-24 hours, so that the wheat grains can fully absorb water and swell.

[0084] F. After the culture medium is cooled, inoculate 5 volumes of the seed liquid (liquid strain) prepared in step (1), and ferment for 18-20 days at a constant temperature of 28 to 30°C, then the fermentation can be completed, and the fermentation product can be stirred evenly to obtain Non-pathogenic Fusarium oxysporum plant vaccine formulations.

[0085...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com