A high-quality dust-proof motor

A motor and dustproof technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of poor dustproof effect, poor heat dissipation performance, high noise, etc., to achieve simple design, improve dustproof effect, and reduce noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

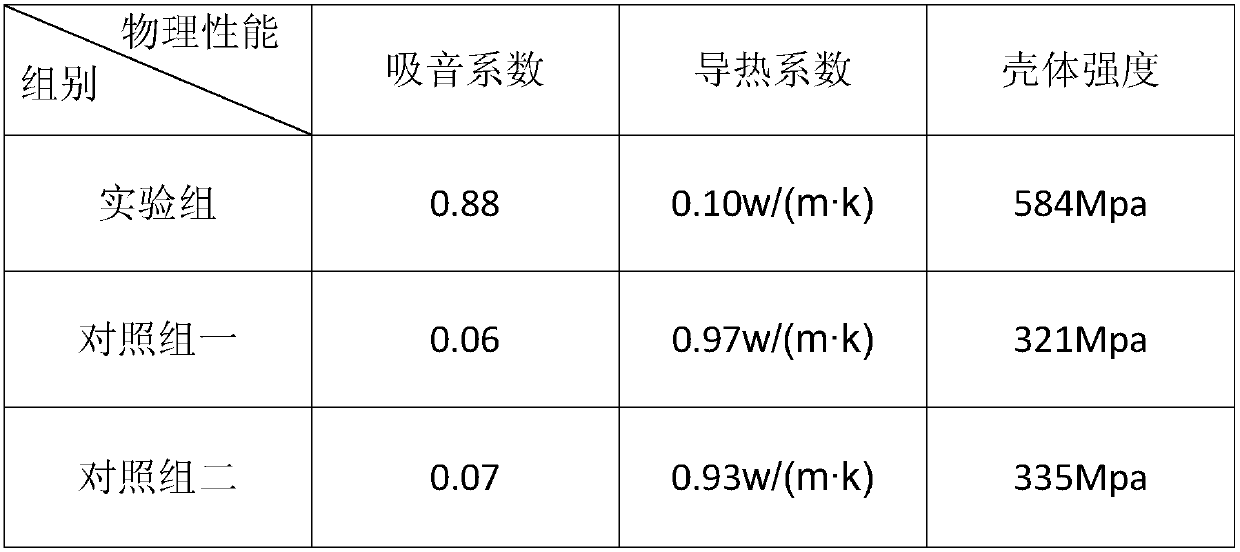

Embodiment 1

[0024] refer to figure 1 As shown, a high-quality dust-proof motor includes a motor housing 1, a front end cover 2 and a rear end cover 3, the front end cover 2, the motor housing 1 and the rear end cover 3 are connected in sequence, and the motor housing 1 It consists of three layers, from the outside to the inside are the outer layer 6, the sound insulation layer 7 and the inner layer 8, the outer layer 6 is provided with reinforcing ribs 13, and the motor housing 1 is provided with a rotor 4 and a stator 5, so The surface of the motor housing 1 is provided with a semiconductor cooling chip 9, and the semiconductor cooling chip 9 is provided with more than one, and the rear end cover 3 and the front end cover 2 are provided with a bearing 14, and the bearing 14 and the rotor 4 are rotating Connected, the rear end cover 3 is provided with a windshield 10, the inside of the windshield 10 is provided with a fan 11, and the windshield 10 is provided with a dustproof net 12.

[...

Embodiment 2

[0041] refer to figure 1 As shown, a high-quality dust-proof motor includes a motor housing 1, a front end cover 2 and a rear end cover 3, the front end cover 2, the motor housing 1 and the rear end cover 3 are connected in sequence, and the motor housing 1 It consists of three layers, from the outside to the inside are the outer layer 6, the sound insulation layer 7 and the inner layer 8, the outer layer 6 is provided with reinforcing ribs 13, and the motor housing 1 is provided with a rotor 4 and a stator 5, so The surface of the motor housing 1 is provided with a semiconductor cooling chip 9, and the semiconductor cooling chip 9 is provided with more than one, and the rear end cover 3 and the front end cover 2 are provided with a bearing 14, and the bearing 14 and the rotor 4 are rotating Connected, the rear end cover 3 is provided with a windshield 10, the inside of the windshield 10 is provided with a fan 11, and the windshield 10 is provided with a dustproof net 12.

[...

Embodiment 3

[0058] refer to figure 1 As shown, a high-quality dust-proof motor includes a motor housing 1, a front end cover 2 and a rear end cover 3, the front end cover 2, the motor housing 1 and the rear end cover 3 are connected in sequence, and the motor housing 1 It consists of three layers, from the outside to the inside are the outer layer 6, the sound insulation layer 7 and the inner layer 8, the outer layer 6 is provided with reinforcing ribs 13, and the motor housing 1 is provided with a rotor 4 and a stator 5, so The surface of the motor housing 1 is provided with a semiconductor cooling chip 9, and the semiconductor cooling chip 9 is provided with more than one, and the rear end cover 3 and the front end cover 2 are provided with a bearing 14, and the bearing 14 and the rotor 4 are rotating Connected, the rear end cover 3 is provided with a windshield 10, the inside of the windshield 10 is provided with a fan 11, and the windshield 10 is provided with a dustproof net 12.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com