Full-closed type light trap sensing control unit and manufacturing method therefor

A technology of sensing control and manufacturing method, which is applied in the direction of measuring devices, instruments, measuring acceleration, etc., can solve the problems of large microcavity space, low particle capture efficiency, and inability to achieve stable particle capture for a long time, so as to isolate interference and Pollution, the effect of improving capture efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

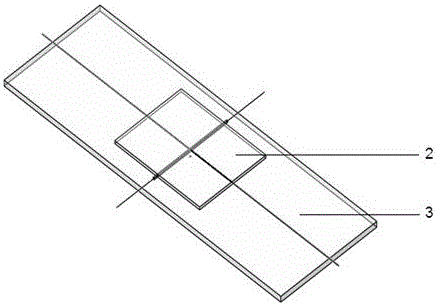

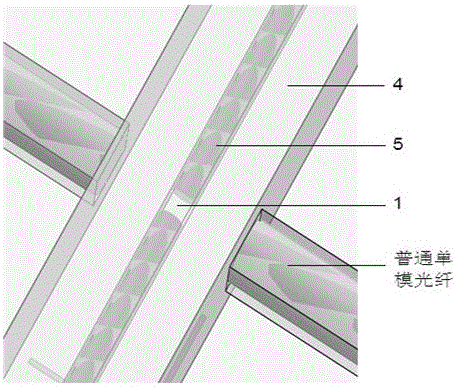

[0045] The invention provides a chip optical trap sensing control unit with high capture efficiency, high optical fiber alignment accuracy, easy processing, assembly and cleaning, such as figure 1 , 2 shown.

[0046] Its manufacturing process can be divided into the assembly of the square capillary 4, the preparation of the PDMS substrate and the overall packaging.

[0047] 1. Assembly of square capillary

[0048] The specific operation steps are:

[0049] 1) Strip the coating of two sections of ultra-fine optical fiber 5 with a diameter of tens of microns (here ultra-fine refers to the diameter of the optical fiber, and the diameter after stripping the coating is about 10-90 microns), and cut with ultra-fine optical fiber 5 Knife handles end faces.

[0050] 2) Use a butane blowtorch to burn off the protective layer on the outside of the square capillary 4, wipe i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com