High-sensitivity self-feedback type alarm circuit for gas sensor

A gas sensor and alarm circuit technology, applied in the electronic field, can solve the problem of not having self-feedback function and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

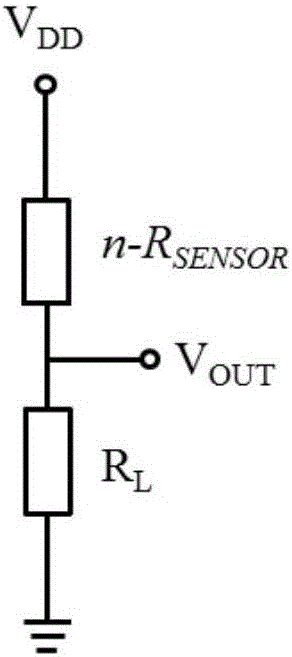

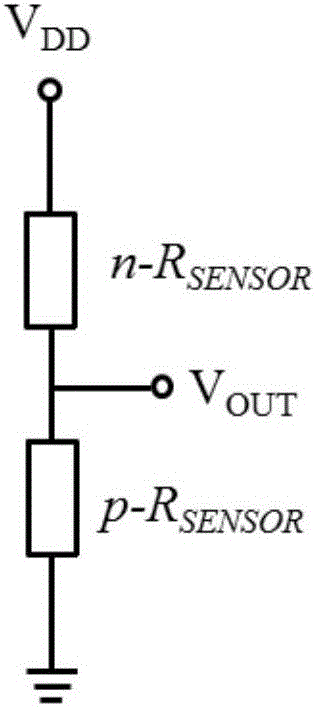

Method used

Image

Examples

example 1

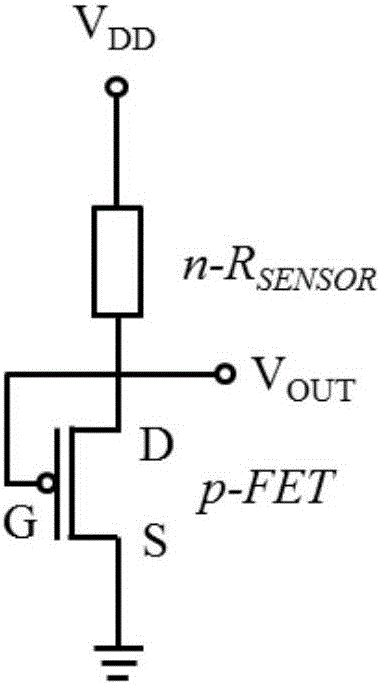

[0024] Example 1, n-type oxide semiconductor SnO 2 The gas sensor is connected in series with the p-type field effect transistor, and one end of the sensor is connected to the positive pole of the test voltage V DD , the source of the transistor is grounded, the gate is short-circuited to the drain, and the voltage across the transistor is taken as the output voltage, such as image 3 shown. When the sensor encounters alcohol, its resistance decreases, causing the current in the circuit to rise and the voltage on the drain of the transistor to increase. At the same time, since the gate and drain of the transistor are short-circuited, the gate voltage and the drain voltage increase synchronously, resulting in a decrease in the current in the p-type transistor. The reduction of the current in the series circuit further leads to a decrease in the voltage division on the sensor, and an increase in the voltage division on the transistor, which is the self-feedback effect. Throug...

example 2

[0025] Example 2, p-type oxide semiconductor Cu 2 O The gas sensor is connected in series with the p-type field effect transistor, and one end of the sensor is connected to the positive pole of the test voltage V DD , the source of the transistor is grounded, the gate is short-circuited to the drain, and the voltage across the sensor is taken as the output voltage, such as Figure 4 shown. When the sensor encounters hydrogen, its resistance increases, causing the current in the circuit to decrease and the voltage between the source and drain of the transistor to decrease. At the same time, since the gate and drain of the transistor are short-circuited, the gate voltage decreases synchronously with the drain voltage, resulting in an increase in the current in the p-type transistor. The increase of the current in the series circuit further leads to the increase of the partial voltage on the sensor, which is the self-feedback effect. Through continuous self-feedback adjustment...

example 3

[0026] Example 3, p-type oxide semiconductor LaFeO 3 The gas sensor is connected in series with the n-type field effect transistor, and the drain of the transistor is connected to the positive pole of the test voltage V DD , the other end of the sensor is grounded, and the gate passes through a fixed series resistor R 0 Short-circuit the source, take the divided voltage of the sensor as the output voltage, such as Figure 5 shown. When the sensor encounters formaldehyde, its resistance increases, causing the current in the circuit to decrease and the voltage between the source and drain of the transistor to decrease. At the same time, since the gate and source of the transistor are short-circuited through a fixed resistor, the decrease in current leads to an increase in the gate voltage, which eventually leads to an increase in the current in the n-type transistor. The increase of the current in the series circuit further leads to the increase of the partial voltage on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com