Ultrafast X-ray Diffraction Imaging Method and System Based on Flash X-ray Machine

An imaging system and imaging method technology, applied in the field of ultrafast X-ray diffraction imaging, can solve the problems of high background density and difficult adjustment of the diffraction optical path, and achieve the effects of simple composition, solving adjustment difficulties, and easy movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

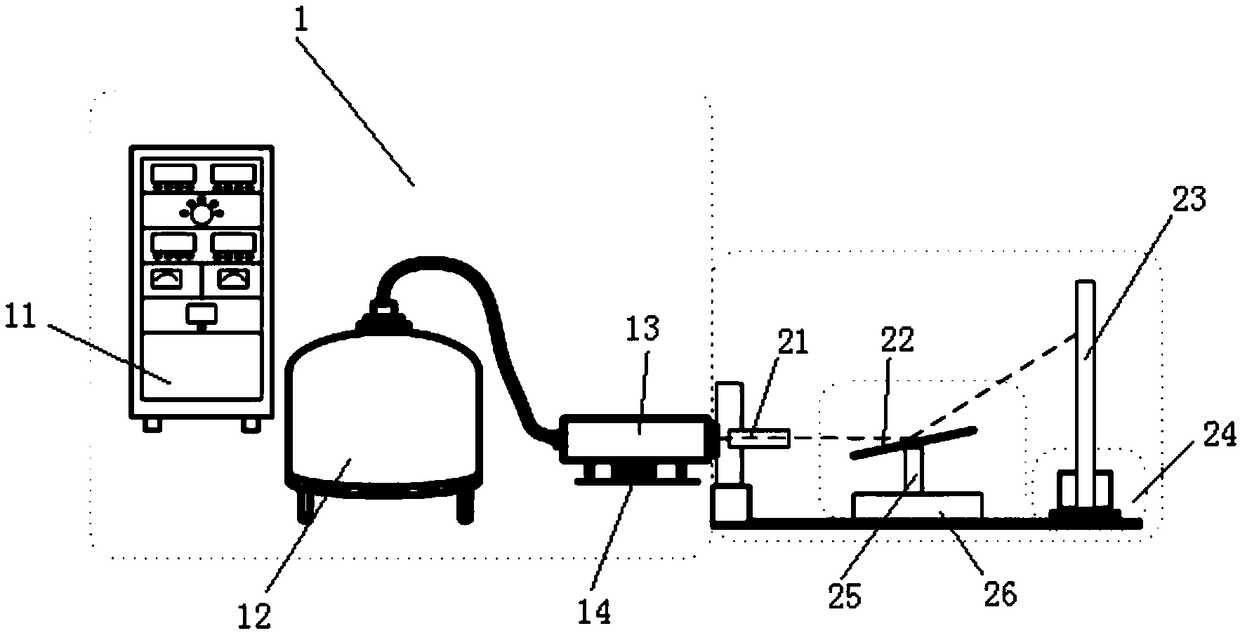

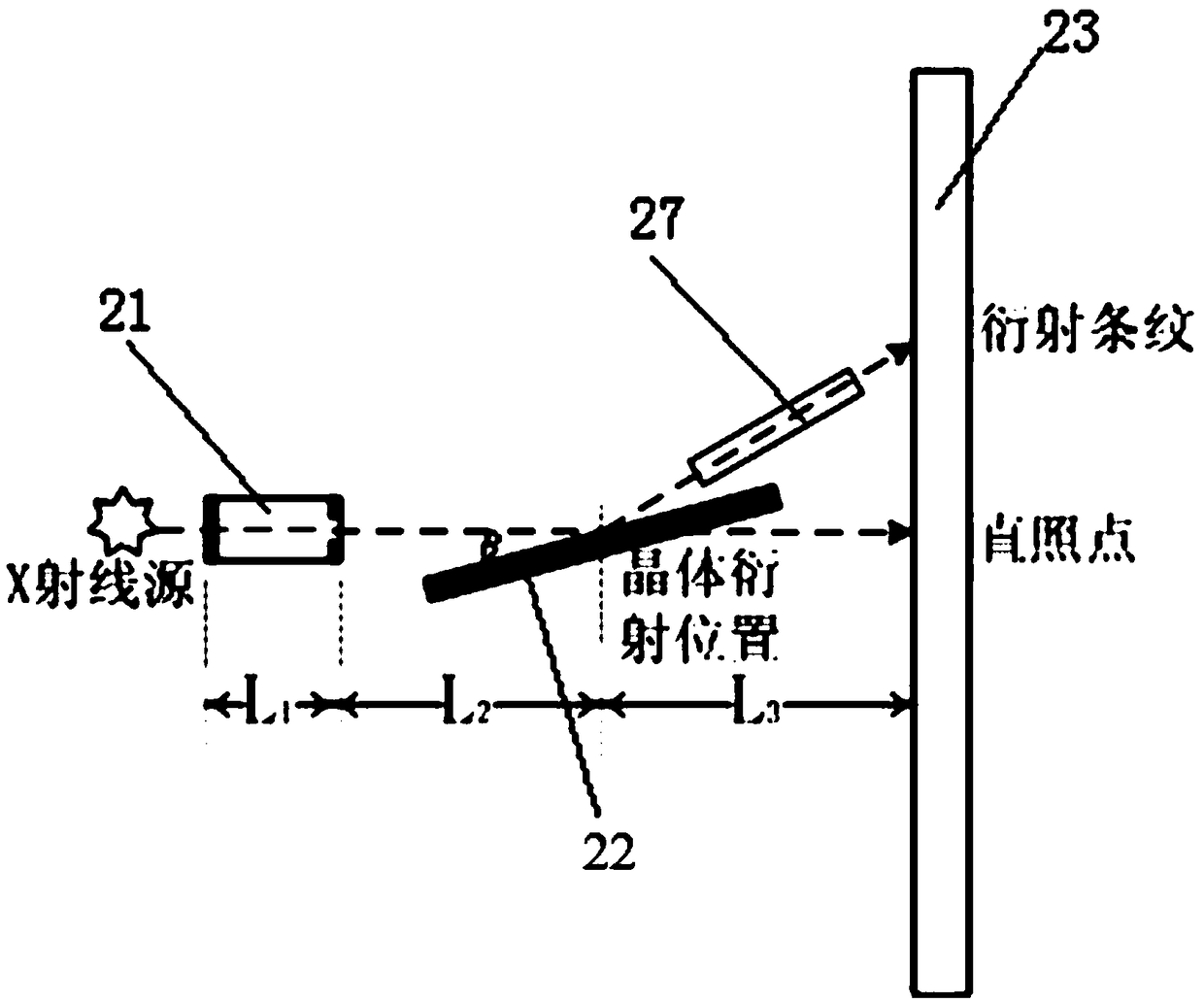

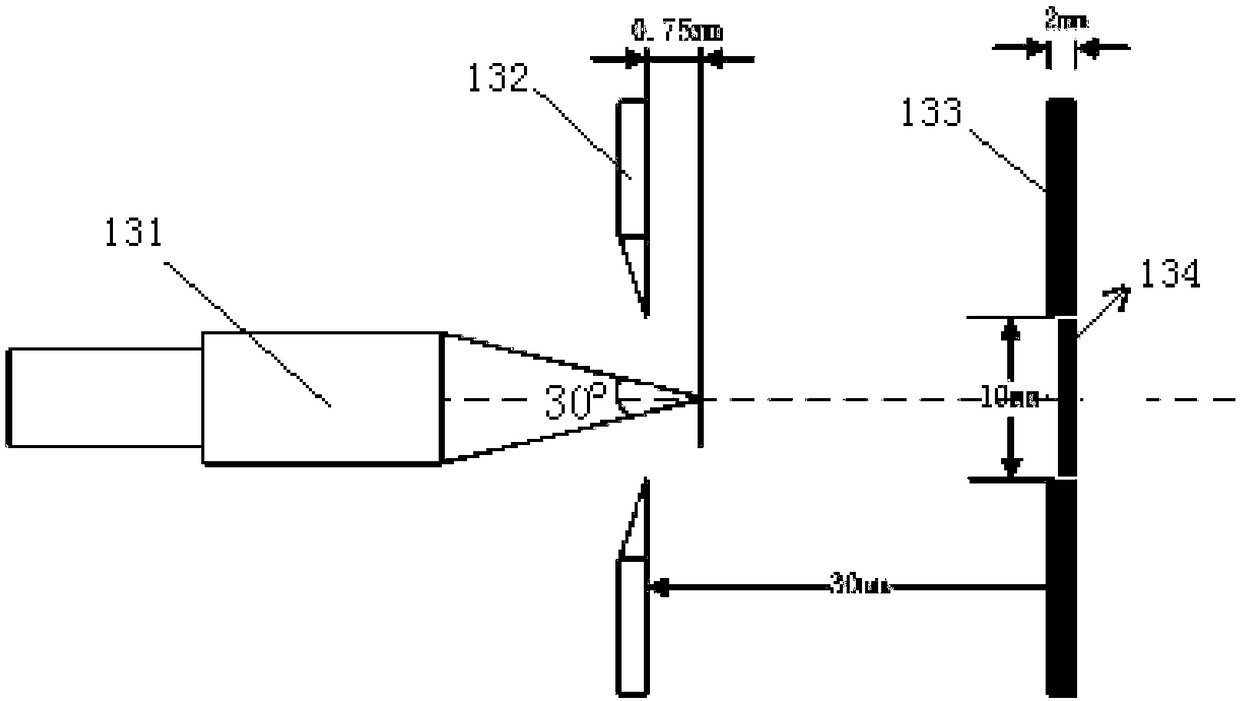

[0052] The specific implementation manners of the present invention will be further described in detail below. The design system of the present invention consists of figure 1 As shown, it includes a flash X-ray machine, a diffraction adjustment subsystem and a detector subsystem. The flash X-ray machine 1 usually consists of three parts, including a high voltage generator 12 , a console 11 and a flash X-ray diode 13 . The flash X-ray diode 13 is based on a diode structure, and the material and shape of the anode 131 determine the proportion of characteristic X-rays in the output energy spectrum. The diffraction adjustment subsystem consists of a front collimator 21, a diffraction angle adjuster and a detector adjustment mechanism. The rear collimator 27 is a cylindrical lead tube, which is used as an optional component to reduce the influence of the scattering background on the imaging results. . The front collimator 21 can choose double tungsten pinholes, and the size and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com