Variable-flow single-working medium cascade heat pump system with parallel heat exchangers

A heat pump system and heat exchanger technology, which is applied to compressors with cascade work, fluid circulation arrangements, lighting and heating equipment, etc. The effect of inter-stage energy regulation, simple system structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

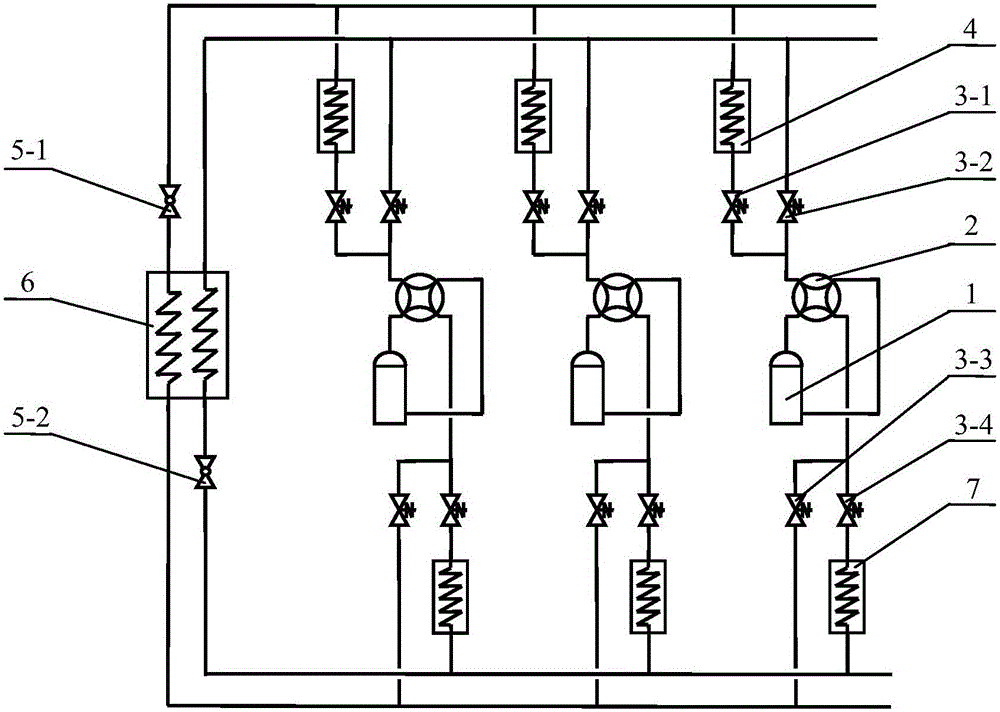

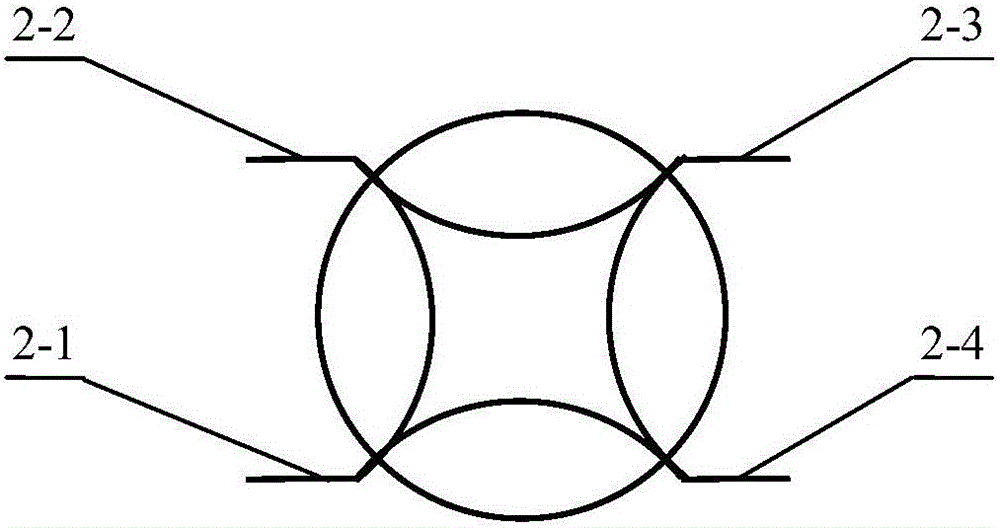

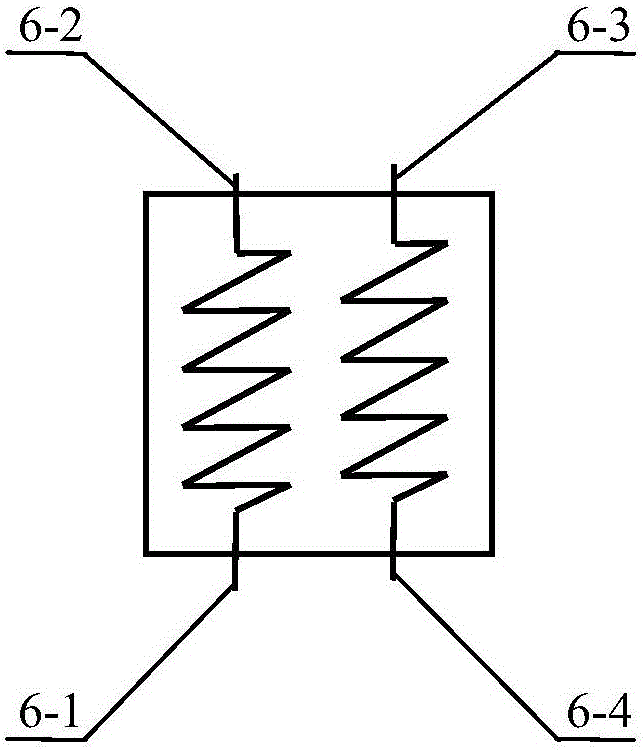

[0024] figure 1 It is a schematic diagram of a cascaded heat pump system with a variable flow single working medium in parallel connection of the first heat exchanger and the second heat exchanger of the present invention, including multiple sets of compressor units connected in parallel, a condensing evaporator 6, a first throttle valve 5-1 and The second throttle valve 5-2, each group of compressors includes a compressor 1, a four-way reversing valve 2, a first solenoid valve 3-1, a second solenoid valve 3-2, a third solenoid valve 3-3, and a second solenoid valve 3-3. Four solenoid valves 3-4, the first heat exchanger 4, and the second heat exchanger 7, the exhaust end of the compressor 1 is connected to the first interface 2-1 of the four-way reversing valve, and the compressor suction connected to the third port 2-3 of the four-way reversing valve, and the first solenoid valve 3-1 is connected in parallel with the second solenoid valve 3-2 to the second port of the four-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com