Multi-fuel electronic injection engine for forklift

A technology for engines and engine cylinders, applied to combustion engines, internal combustion piston engines, engine components, etc., to achieve the effect of increasing air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

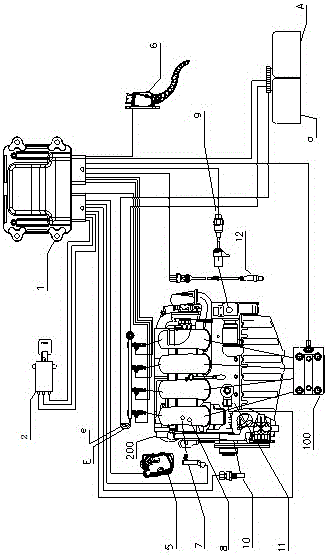

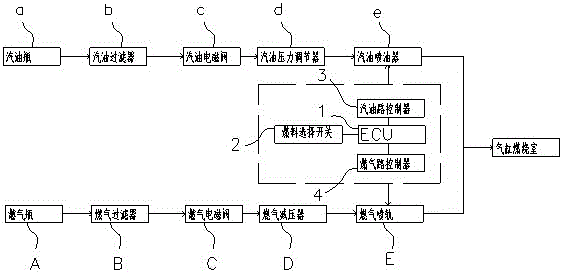

[0014] With reference to the accompanying drawings, a multi-fuel EFI engine for a forklift includes a fuel supply system for supplying gasoline or natural gas to the engine cylinder combustion chamber, an electronic control system for controlling the fuel supply,

[0015] The gasoline fuel supply system is sequentially arranged with gasoline bottle a, gasoline filter b, gasoline solenoid valve c, gasoline pressure regulator d, gasoline injector e; the described natural gas fuel supply system is sequentially arranged with gas cylinder A, Gas filter B, gas solenoid valve C, gas pressure reducer D, gas injection rail E;

[0016] Described electronic control system controls the supply of engine gasoline and natural gas fuel, comprises the ECU1 that controls gasoline, natural gas fuel channel switch and switching, fuel selection switch 2, the gasoline circuit controller 3 that controls gasoline injector e injection quantity, Gas circuit controller 4, electronic throttle valve 5, el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com