Vortex rotary compressor

A scroll compressor and compressor technology, applied in the direction of rotary piston machinery, rotary piston pump, rotary piston/swing piston pump components, etc., can solve the problem of high installation accuracy, heavy mass, exhaust temperature Advanced problems, to achieve the effect of stable operation, simple structure and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

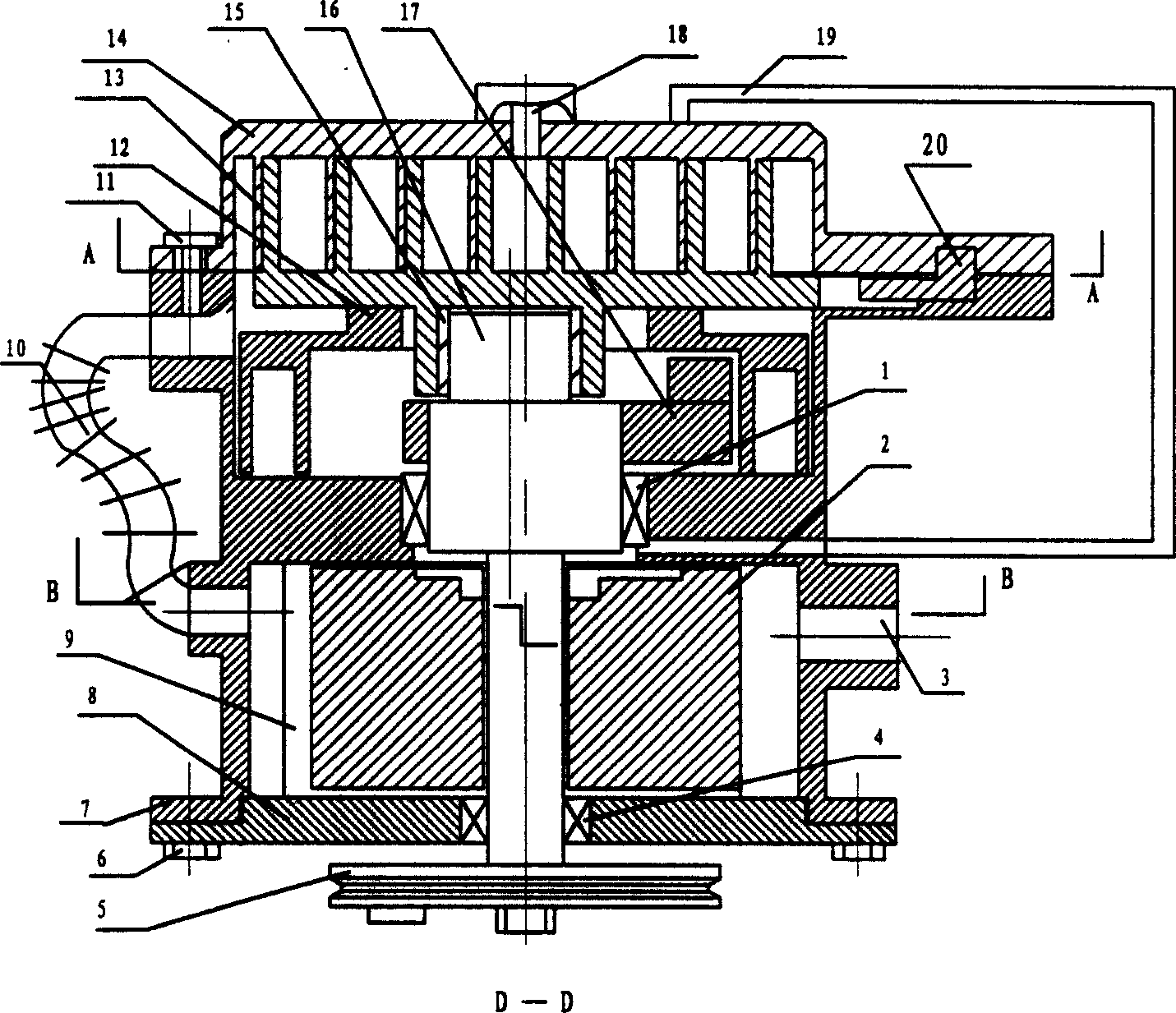

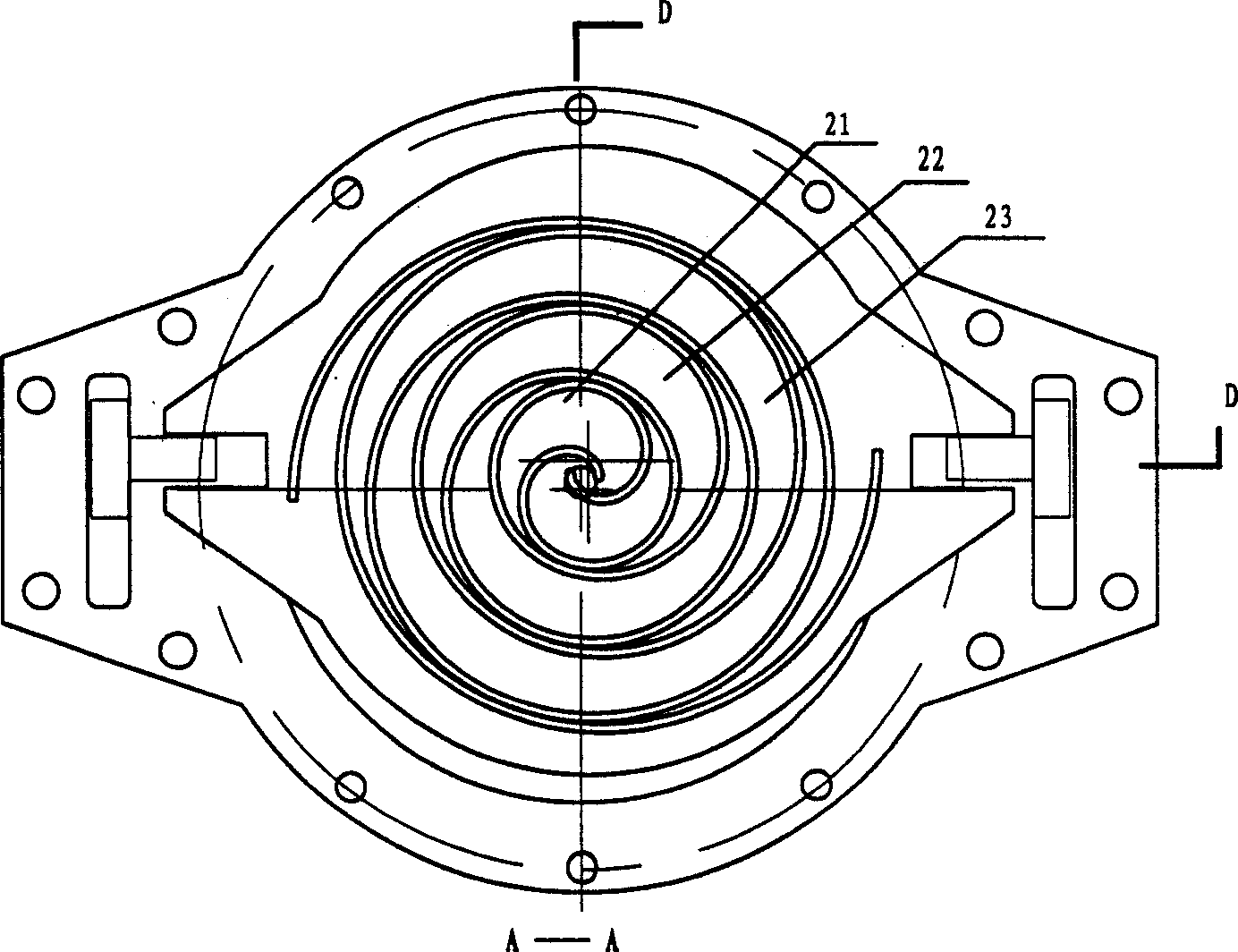

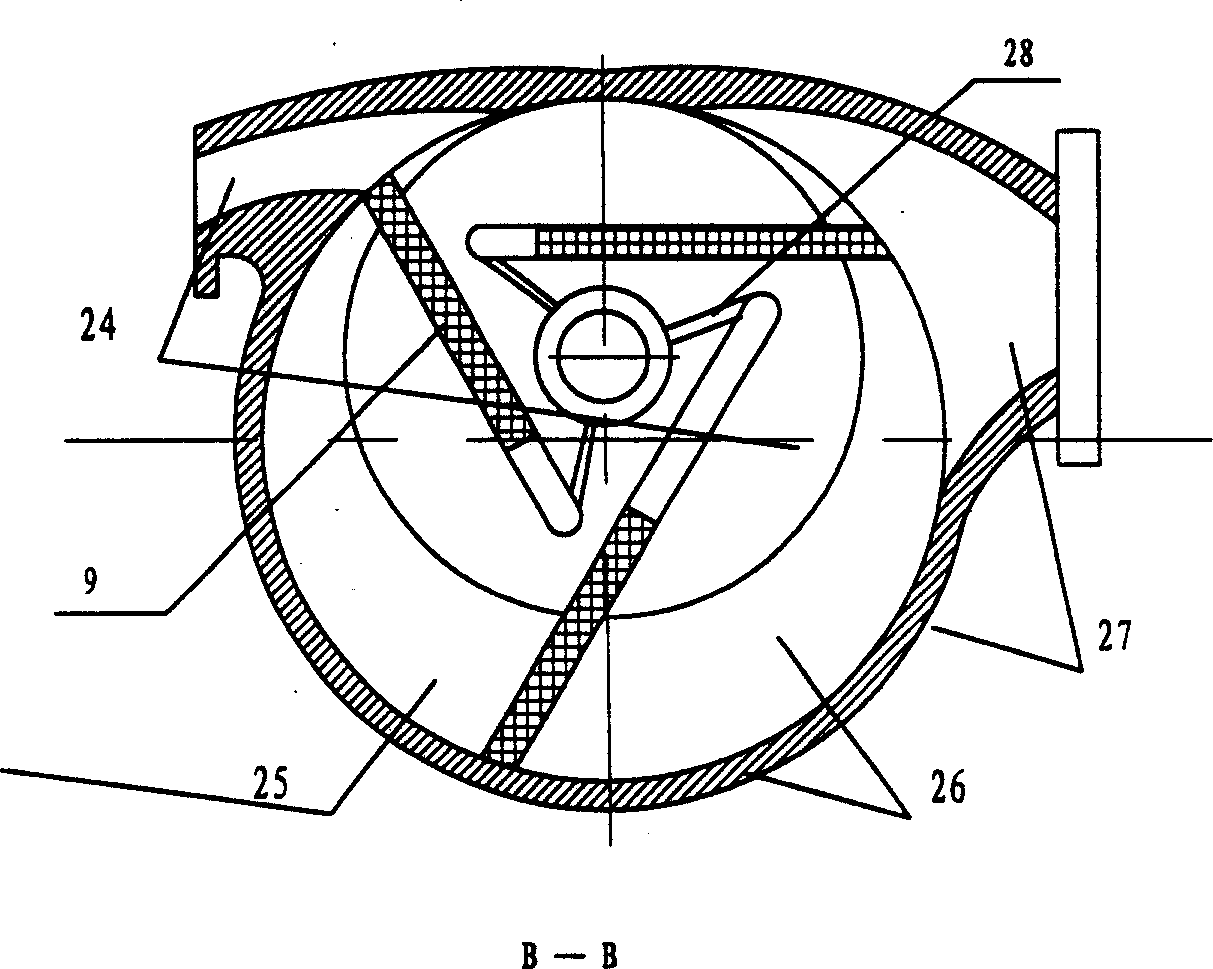

[0020] Such as Figure 1 ~ Figure 3 As shown, the scroll rotary compressor of the present invention has a main bearing 1 supporting a main shaft 16, an auxiliary bearing 4, and an orbiting scroll bearing 15, and a belt pulley 5, a main balancer 17, a fuselage 7 and an end cover are installed on the main shaft 8 are connected by screws 6, the lower end of the main shaft 16 is equipped with the rotor 2 contained in the fuselage 7, the rotor 2 is equipped with a sliding plate 9, the upper end of the main shaft 16 is equipped with a movable scroll 13, and the static vortex matched with the movable scroll 13 The roll 14 is fastened to the fuselage 7 with bolts 11 . In this way, the scroll and rotary compressors are connected in series.

[0021] The scroll rotary compressor of the present invention is equipped with T-shaped blocks 20 symmetrically on both sides of the movable scroll 13 and the static scroll 14. A part of the T-shaped blocks 20 is slidingly fitted with the chute of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com