Reinforced heat-resistant polylactic acid electrostatic spun fibrous membrane and preparation method therefor

A technology of electrospinning and electrospinning solution, which is applied in the field of reinforcing heat-resistant polylactic acid electrospinning fiber film and its preparation, can solve the problem of large addition of reinforcing materials, small increase in strength and heat resistance, and polylactic acid phase. problems such as poor capacitance, to achieve the effect of saving dissolution time, increasing heat resistance, and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 163 mg of graphene oxide ultrasonically dispersed in 100 mL of methanol, add 1.487 g of zinc nitrate hexahydrate, stir to fully mix and dissolve, and at the same time weigh 0.801 g of dimethylimidazole and dissolve in 100 mL of methanol, then mix the above two solutions. Stir it to react for 1h, let it stand for 3h, centrifuge, wash, and dry to prepare a composite enhancer.

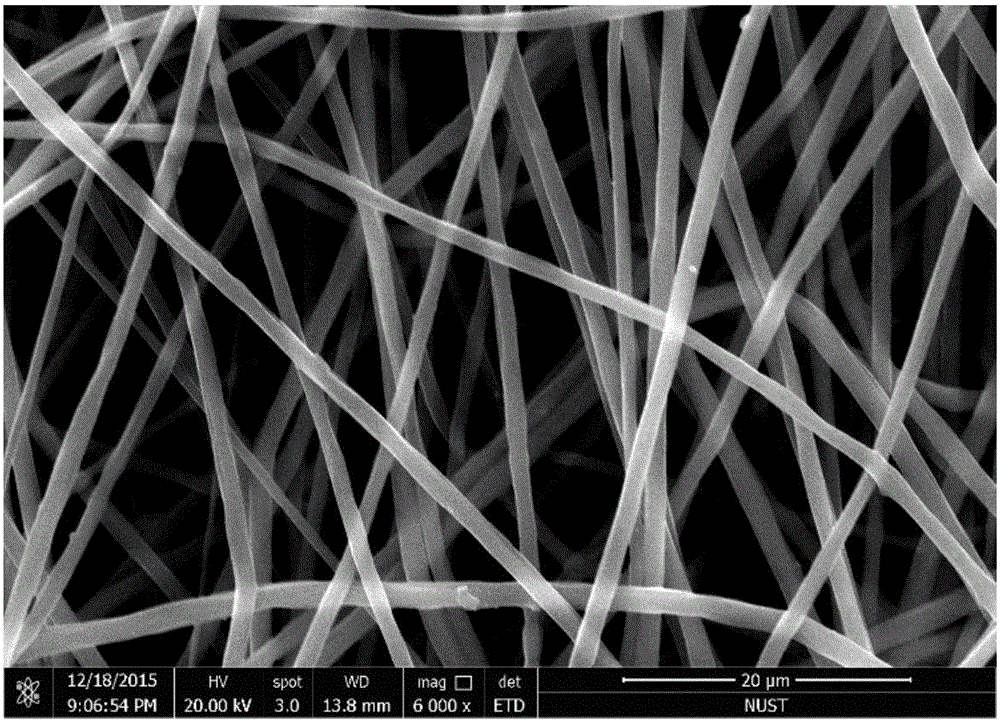

[0028] Weigh 1.09g of polylactic acid and dissolve it in 8mL of dichloromethane, and magnetically stir for 2h to fully dissolve it. Weigh 1.09 mg of the composite enhancer and disperse it in 2 mL of N’N-dimethylformamide, and sonicate it for 30 minutes to make it evenly dispersed. Subsequently, under stirring, the dispersion of the composite enhancer was added dropwise to the polylactic acid solution and mixed, and blended for 3 hours. Electrospinning of the electrospinning solution is carried out with an electrospinning device, the setting voltage is 17KV, the spinning solution advancing speed...

Embodiment 2

[0030] Weigh 163 mg of graphene oxide ultrasonically dispersed in 100 mL of methanol, add 1.487 g of zinc nitrate hexahydrate, stir to fully mix and dissolve, and at the same time weigh 1.602 g of dimethylimidazole to dissolve in 100 mL of methanol, and then mix the above two solutions. Stir to react for 1h, stand for 8h, centrifuge, wash, and dry to prepare a composite enhancer.

[0031] Weigh 1.55g of polylactic acid and dissolve it in 8mL of dichloromethane, and magnetically stir for 2h to fully dissolve it. Weigh 1.09 mg of the composite enhancer and disperse it in 2 mL of N’N-dimethylformamide, and sonicate it for 30 minutes to make it evenly dispersed. Subsequently, under stirring, the dispersion of the composite enhancer was added dropwise to the polylactic acid solution and mixed, and blended for 6 hours. Electrospinning of the electrospinning solution is carried out with an electrospinning device, the setting voltage is 24KV, the spinning solution advancing speed is 1mL...

Embodiment 3

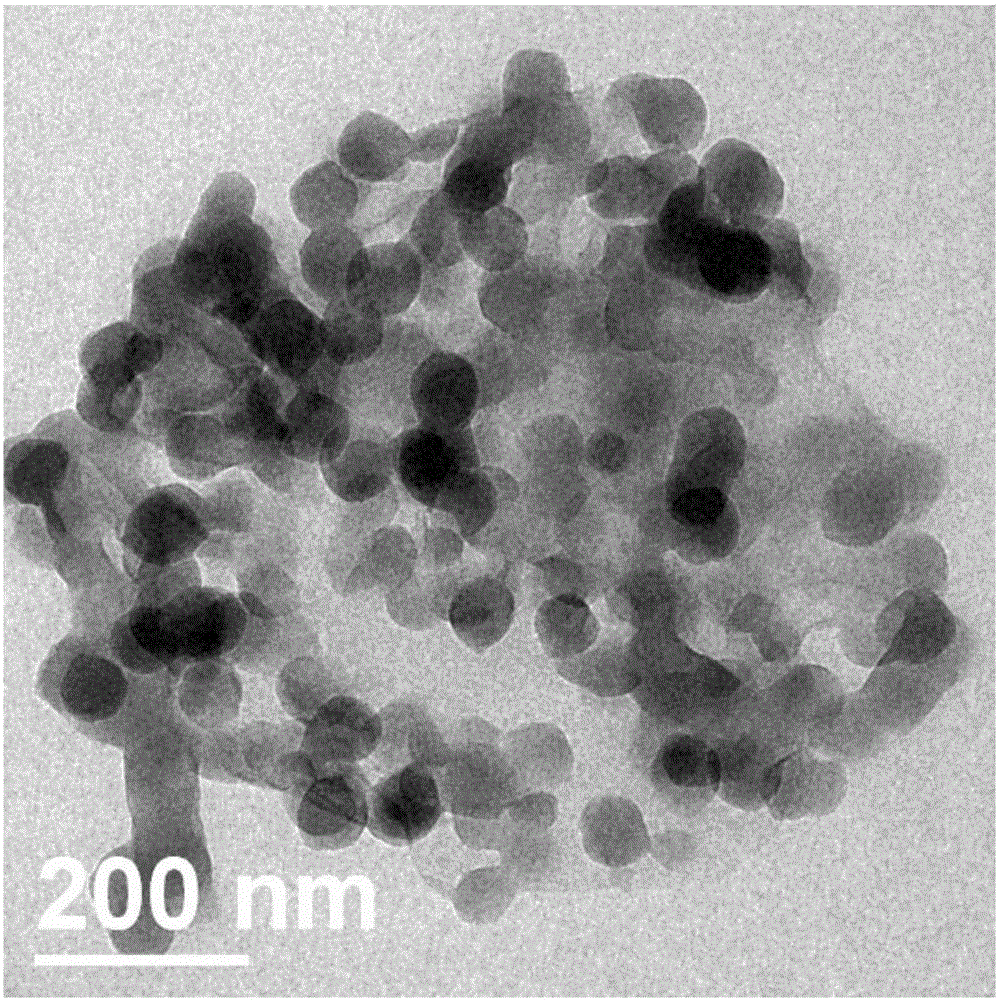

[0033] Weigh 163 mg of graphene oxide ultrasonically dispersed in 100 mL of methanol, add 1.487 g of zinc nitrate hexahydrate, stir to fully mix and dissolve, and at the same time weigh 1.602 g of dimethylimidazole to dissolve in 100 mL of methanol, and then mix the above two solutions. Stir it to react for 1h, leave it to stand for 6h, centrifuge, wash, and dry to prepare a composite enhancer. figure 1 It shows that ZIF-8 is successfully loaded on graphene oxide sheet.

[0034] Weigh 1.39 g of polylactic acid and dissolve it in 8 mL of dichloromethane, and magnetically stir for 2 hours to fully dissolve it. Weigh 1.39 mg of the composite enhancer and disperse it in 2 mL of N’N-dimethylformamide, and sonicate it for 30 minutes to make it uniformly dispersed. Subsequently, under stirring, the ZIF-8 dispersion was added dropwise to the polylactic acid solution and mixed, and blended for 3 hours. Electrospinning of the electrospinning solution is carried out with an electrospinning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com