An Improved Electroplating Device for Zinc Alloy Zipper

An electroplating device and technology of zinc alloy, applied in the direction of electrodes, electrolysis components, electrolysis process, etc., can solve the problems of rough zipper elements, uneven zipper plating, scratched elements, etc., and achieve the effect of uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

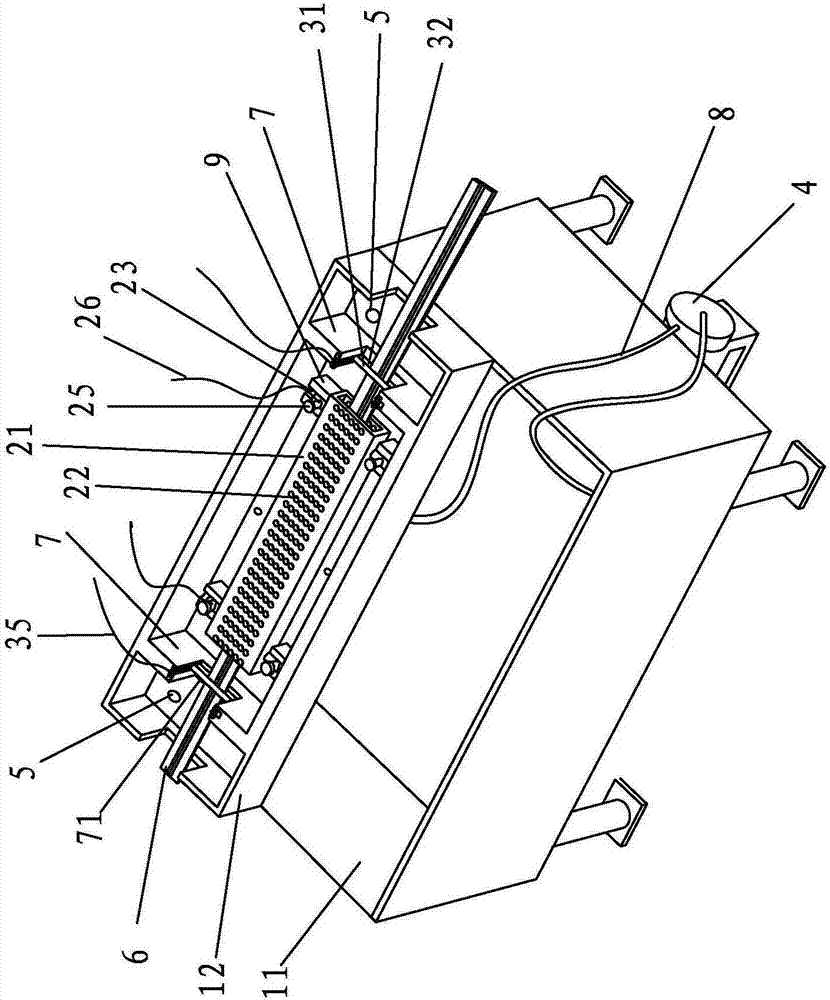

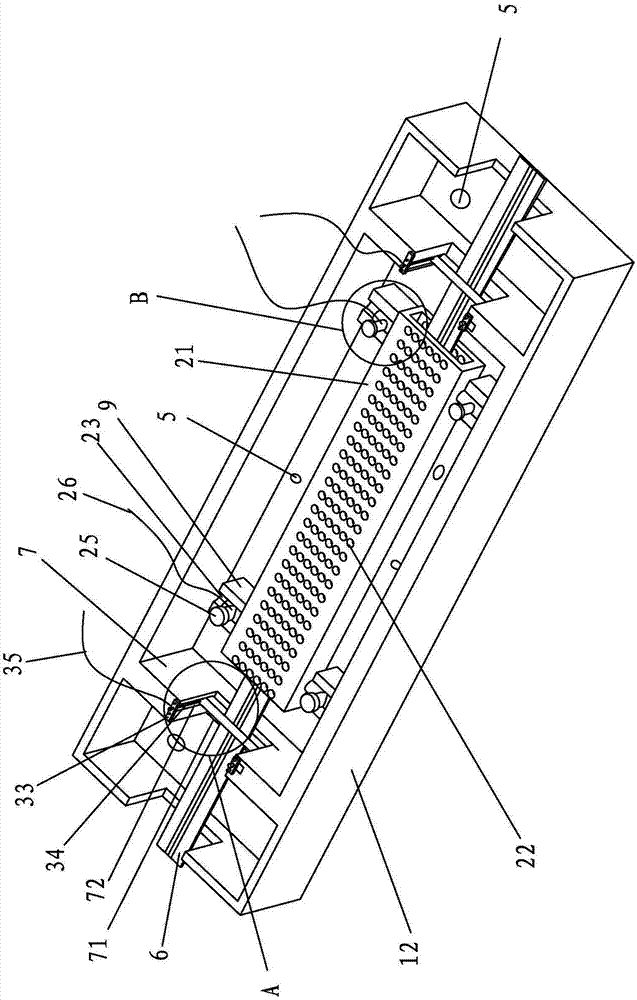

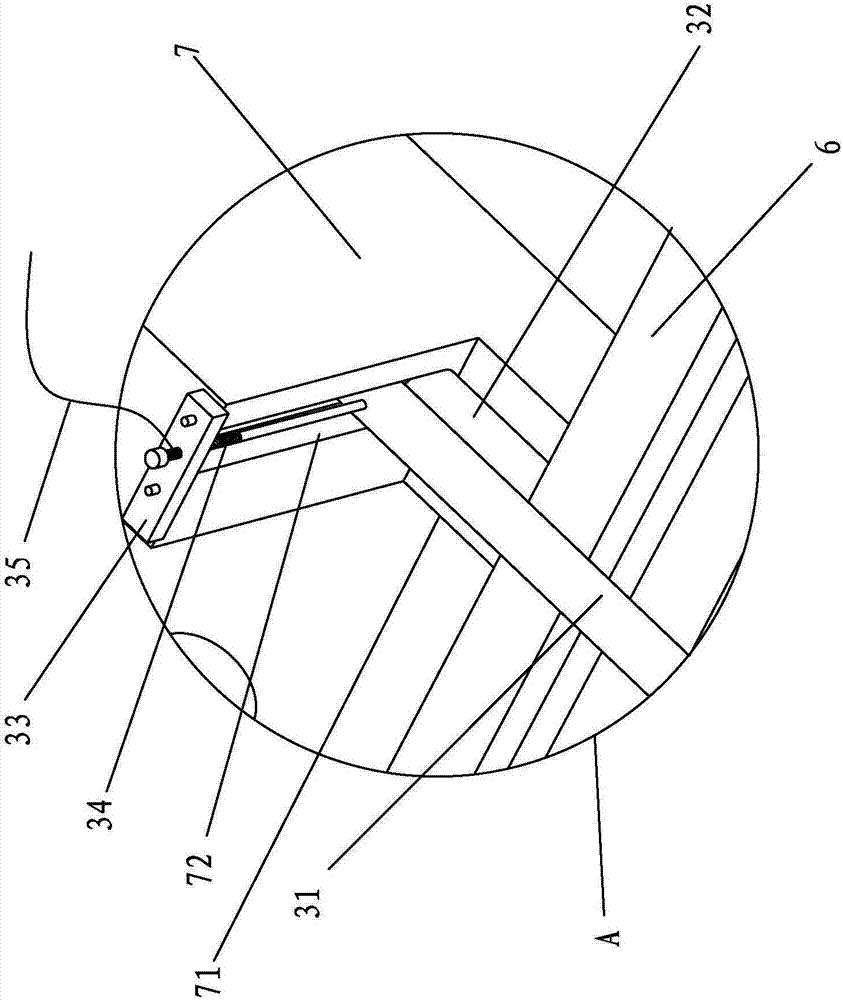

[0042] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

[0043] refer to Figure 1 to Figure 8 As shown, an improved zinc alloy zipper electroplating device includes a plating tank, an anode device, a cathode device in electrical contact with the zipper, and a zipper transmission device that drives the zipper 6 to move along the length of the plating tank. The plating tank consists of a liquid storage tank 11 and an electroplating tank 12 located above the liquid storage tank 11. The liquid storage tank 11 is used for placing electroplating solutions and adding electroplating chemicals. The bottom of the electroplating tank 12 is provided with a perforation (not shown), the perforation is arranged below the anode plate, and a conduit 8 is arranged between the perforation and the output port of the circulation pump. The bottom of the electroplating tank 12 is also p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com