Copper alloy slide fastener heat tinting solution stirrer apparatus

A stirring device and mixer technology, which is applied in the coating process of metal materials, etc., can solve the problems of slow neutralization speed, high labor intensity, and difficult storage of liquid medicine, and achieve the effect of low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

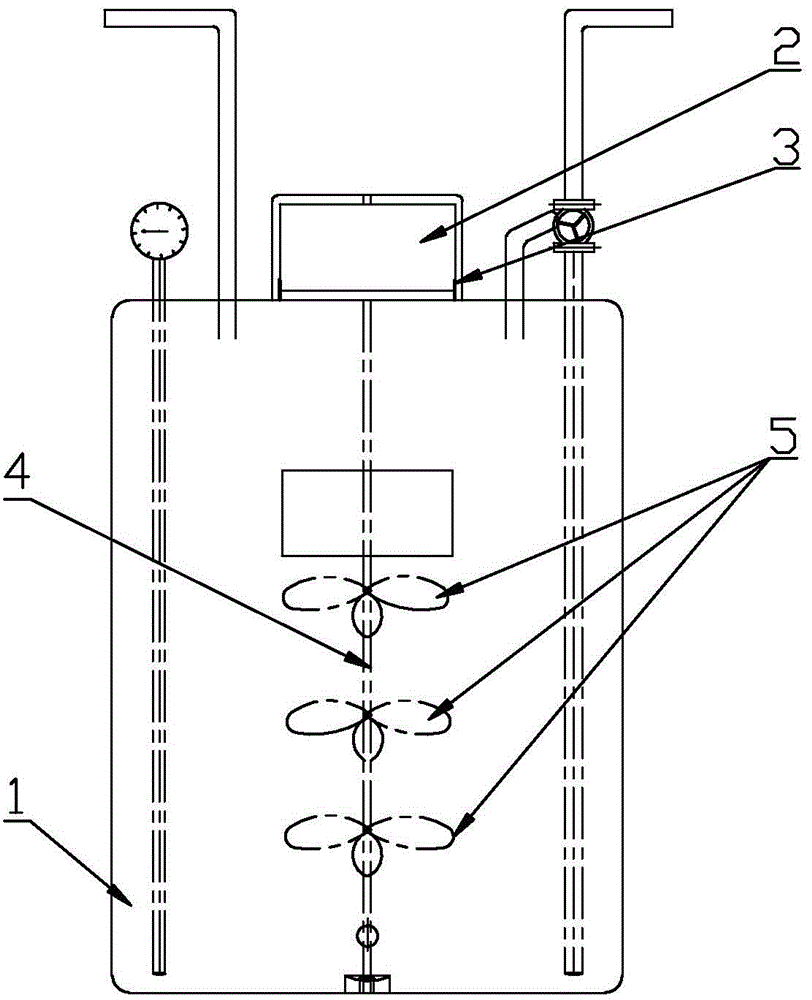

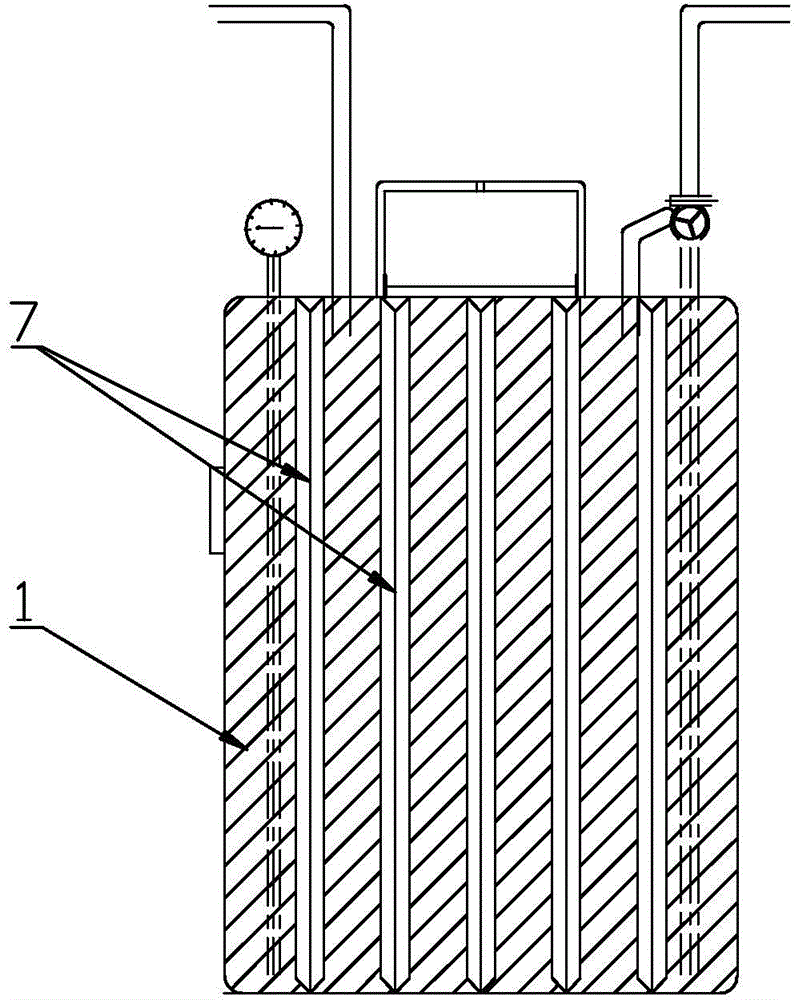

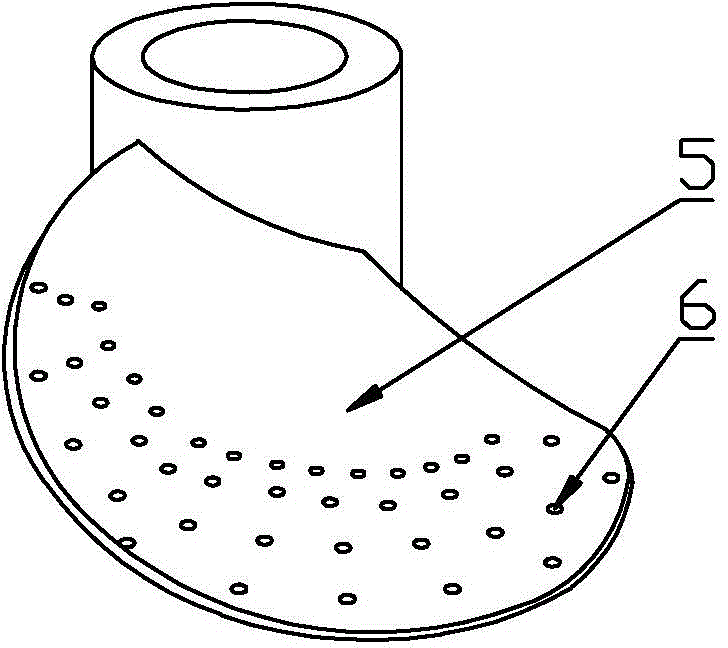

[0021] Such as Figure 1-3 Shown, a kind of copper alloy zipper oxidation coloring solution stirrer device, it comprises hollow medicine storage tank 1, motor 2 and stirring device, described motor 2 is fixed on the top of medicine storage tank by motor protection frame 3, and described motor The protective shell frame 3 is a rectangular frame structure, the motor 2 is fixedly installed in the center of the motor protective shell frame 3, the stirring device is fixed inside the medicine storage tank through the main shaft 4, and one end of the main shaft 4 is fixedly connected to the motor 2, so The other end of the main shaft 4 is fixedly connected to a stirring device, the stirring device includes a three-stage stirring blade 5, and the three-stage stirring blade 5 is fixedly sleeved on the lower part of the main shaft 4 side by side up and down, and the spiral direction of the three-stage stirring blade 5 is different. , the outer edge of each stage of the stirring blade 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com