A kind of ozone sensitive coating and preparation method thereof

An ozone gas and coating technology, applied in the coating, metal material coating process, melt spraying and other directions, can solve the problems of unstable coating structure, affecting the gas sensitivity of the coating, etc., and achieve low production cost and high performance. Superior, avoid the effect of grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

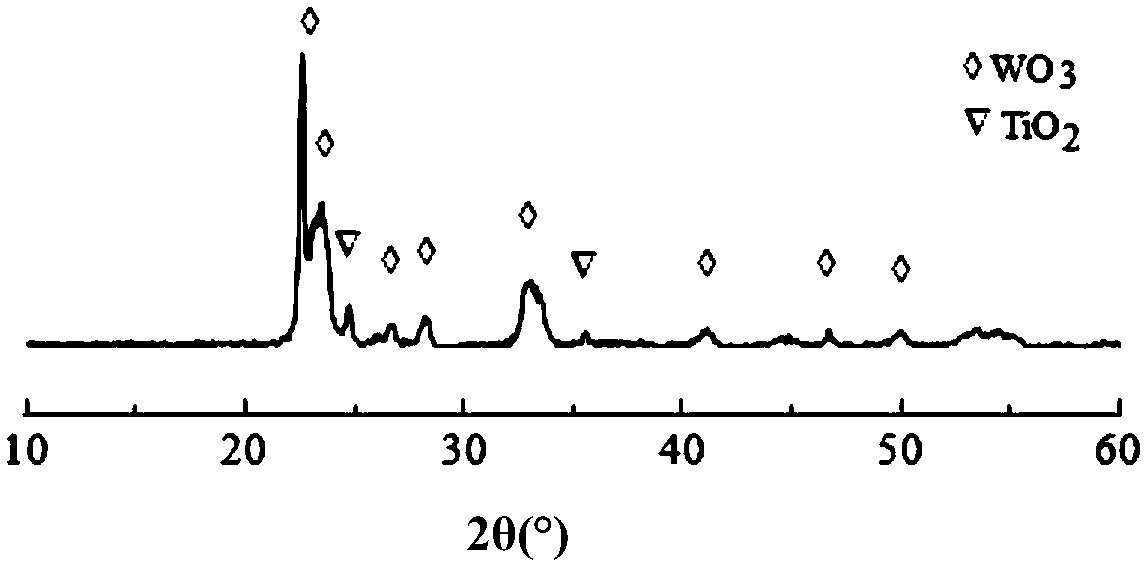

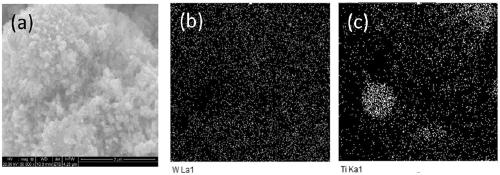

[0059] In this embodiment, the base material is a ceramic tube with a diameter of 2 mm and a hole diameter of about 1 mm, and the surface of the base is nano-TiO 2 -WO 3 The thickness of the nanocomposite coating is 1000nm, and the coating is well combined with the matrix material; the surface of the coating is a porous structure, mainly composed of nano-sized TiO 2 and WO 3 Grain stacking, in which WO 3 The grain size is about 10nm, TiO 2 The grain size range is about 25nm, and the specific preparation method of the ozone gas-sensitive coating is as follows:

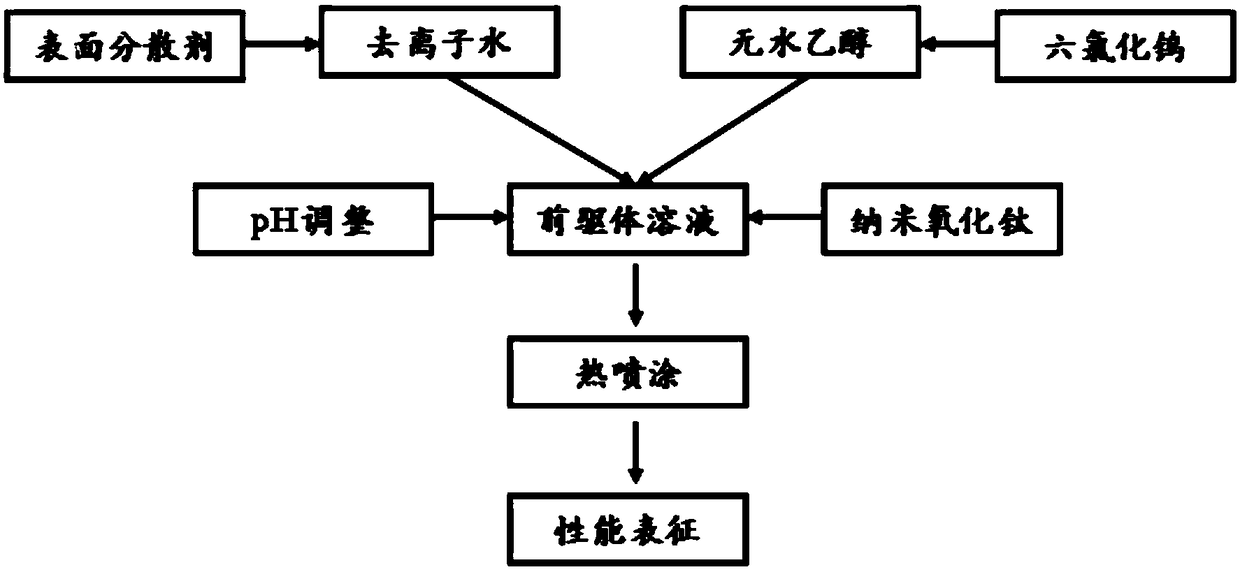

[0060] 1. Preparation of nano-TiO 2 -WCl 6 Precursor solution: fully dissolve the surface dispersant and deionized water, fully dissolve tungsten hexachloride and anhydrous ethanol, then mix the above two solutions and stir magnetically for 30min to make them evenly mixed. A certain amount of nano-P25 is added to the above uniform mixed solution, and the pH value is adjusted with ammonia water to obtain spraying r...

Embodiment 2

[0068] In this embodiment, the base material is a ceramic tube with a diameter of 2 mm and a hole diameter of about 1 mm, and the surface of the base is nano-TiO 2 -WO 3 The thickness of the nanocomposite coating is 300nm, and the coating is well combined with the matrix material; the surface of the coating is a porous structure, mainly composed of nano-sized TiO 2 and WO 3 Grain stacking, in which WO 3 The grain size is about 15nm, TiO 2 The grain size range is about 30nm, and the specific preparation method of the ozone gas-sensitive coating is as follows:

[0069] 1. Preparation of nano-TiO 2 -WCl 6 Precursor solution: fully dissolve the surface dispersant and deionized water, fully dissolve tungsten hexachloride and anhydrous ethanol, then mix the above two solutions and stir magnetically for 30min to make them evenly mixed. Add a certain amount of anatase phase nano-TiO to the above uniform mixture 2 , and adjust the pH value with ammonia water to obtain spraying r...

Embodiment 3

[0077] In this embodiment, the base material is a ceramic tube with a diameter of 2 mm and a hole diameter of about 1 mm, and the surface of the base is nano-TiO 2 -WO 3 The thickness of the nanocomposite coating is 1000nm, and the coating is well combined with the matrix material; the surface of the coating is a porous structure, mainly composed of nano-sized TiO 2 and WO 3 Grain stacking, in which WO 3 The grain size is 15.18nm, TiO 2 The grain size range is 25nm, and the specific preparation method of the ozone gas-sensitive coating is as follows:

[0078] 1. Preparation of nano-TiO 2 -WCl 6 Precursor solution: fully dissolve the surface dispersant and deionized water, fully dissolve tungsten hexachloride and anhydrous ethanol, then mix the above two solutions and stir magnetically for 30min to make them evenly mixed. A certain amount of nano-P25 is added to the above uniform mixed solution, and the pH value is adjusted with ammonia water to obtain spraying raw materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com